At its core, vacuum heat treatment is about achieving ultimate control over the metallurgical process. By removing the atmosphere from the heating chamber, this technology fundamentally prevents undesirable surface reactions like oxidation and decarburization. This results in components with a superior surface finish, enhanced and more uniform mechanical properties, and a level of process repeatability that is difficult to achieve with traditional atmospheric methods.

The primary benefit of vacuum heat treatment is not just one single advantage, but how the vacuum environment systematically eliminates variables. By removing atmospheric gases, you gain precise control over the material's surface chemistry and internal structure, leading to higher quality, more consistent, and often more cost-effective results.

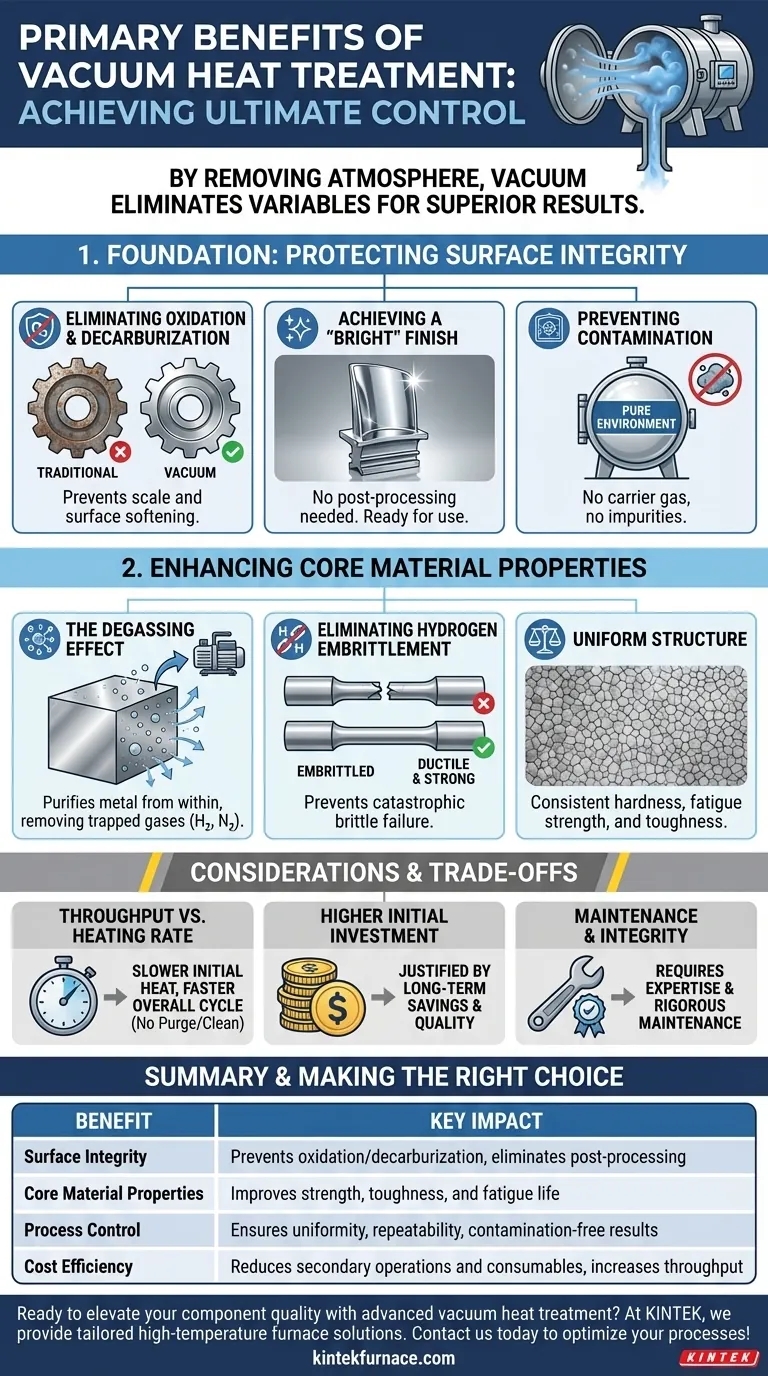

The Foundation: How Vacuum Protects Surface Integrity

The most immediate and obvious benefit of vacuum heat treatment occurs at the surface of the workpiece. By removing air, you remove the reactive elements that cause degradation at high temperatures.

Eliminating Oxidation and Decarburization

In a traditional furnace, the oxygen in the air reacts with the hot metal surface, forming an oxide layer, or scale. Similarly, carbon can be drawn out of the steel's surface, a process called decarburization, which softens the material.

A vacuum environment is virtually free of oxygen, completely preventing oxidation. This ensures the part's dimensions and surface chemistry remain unchanged, just as you designed them.

Achieving a "Bright" Finish Without Post-Processing

Because no oxidation occurs, parts emerge from a vacuum furnace with a clean, bright, and often shiny surface.

This eliminates the need for costly and time-consuming secondary operations like sandblasting, pickling, or grinding to remove scale. The part is often ready for use or final assembly immediately after treatment.

Preventing Contamination from Impure Gases

Even controlled atmosphere furnaces can introduce contaminants if the protective gases (like nitrogen or argon) are not perfectly pure.

Vacuum treatment inherently avoids this risk. There is no carrier gas to introduce impurities, ensuring the environment is exceptionally clean and non-reactive.

Enhancing Core Material Properties

The benefits of a vacuum extend deep into the material itself, improving its fundamental mechanical properties by purifying the metal from within.

The Degassing Effect: Purifying the Metal from Within

At high temperatures and under vacuum, trapped gases within the metal—primarily hydrogen and nitrogen—are drawn out to the surface and removed by the vacuum system.

This degassing effect results in a cleaner, purer base material with improved internal integrity. This is especially critical for high-performance alloys.

Eliminating Hydrogen Embrittlement

Hydrogen is a notorious impurity that can cause catastrophic, brittle failure in high-strength steels.

Because vacuum heat treatment actively removes hydrogen from the metal, it completely eliminates the risk of hydrogen embrittlement, a critical safety and reliability advantage for high-stress components.

Uniform Structure for Predictable Performance

Vacuum furnaces primarily heat parts using thermal radiation. This method is inherently slow and exceptionally uniform, ensuring the entire part, regardless of its complexity, reaches temperature evenly.

This uniform heating and controlled cooling lead to a more consistent grain structure and hardness throughout the component, improving properties like fatigue strength, toughness, and plasticity.

Understanding the Trade-offs and Considerations

While powerful, vacuum technology is not a universal solution. A trusted advisor must acknowledge its specific operational context and limitations.

Throughput vs. Heating Rate

The reliance on radiation means initial heating cycles can be slower than forced convection in an atmosphere furnace.

However, the overall process time, or throughput, is often faster. This is because you eliminate lengthy purge cycles required for atmosphere furnaces and the extensive post-treatment cleaning operations.

Higher Initial Capital Investment

Vacuum furnaces are complex machines that represent a significant capital investment compared to many conventional atmosphere furnaces.

This higher upfront cost is typically justified by long-term savings from reduced post-processing, lower consumables (no process gas), higher yields, and improved product quality.

Maintenance and Vacuum Integrity

Operating a vacuum furnace requires specific expertise. Maintaining vacuum integrity is paramount, as even a small leak can compromise the entire process.

This necessitates rigorous maintenance schedules and skilled technicians to ensure the pumps, seals, and chamber remain in perfect working order.

Making the Right Choice for Your Application

Selecting the right heat treatment method depends entirely on your material, component requirements, and production goals.

- If your primary focus is surface quality and aesthetics: Vacuum is unparalleled for parts requiring a clean, scale-free finish directly from the furnace, eliminating downstream cleaning costs.

- If your primary focus is ultimate mechanical performance: Vacuum's degassing and uniform quenching are critical for high-stress components where fatigue life and toughness are non-negotiable.

- If you are working with reactive materials (e.g., Titanium, refractory metals): Vacuum is often the only viable choice to prevent the surface embrittlement that occurs in the presence of oxygen or nitrogen.

- If your primary focus is process consistency and automation: The highly controllable and repeatable nature of modern vacuum furnaces is ideal for high-volume production where part-to-part uniformity is essential.

By removing the atmosphere from the equation, vacuum heat treatment empowers you with direct control over the final properties of your components.

Summary Table:

| Benefit | Key Impact |

|---|---|

| Surface Integrity | Prevents oxidation and decarburization, eliminates post-processing |

| Core Material Properties | Improves mechanical strength, toughness, and fatigue life |

| Process Control | Ensures uniformity, repeatability, and contamination-free results |

| Cost Efficiency | Reduces secondary operations and consumables, increasing throughput |

Ready to elevate your component quality with advanced vacuum heat treatment? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide tailored high-temperature furnace solutions, including Vacuum & Atmosphere Furnaces, Muffle, Tube, Rotary Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure we meet your unique experimental and production needs, delivering enhanced performance, consistency, and cost savings. Contact us today to discuss how we can optimize your heat treatment processes!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance