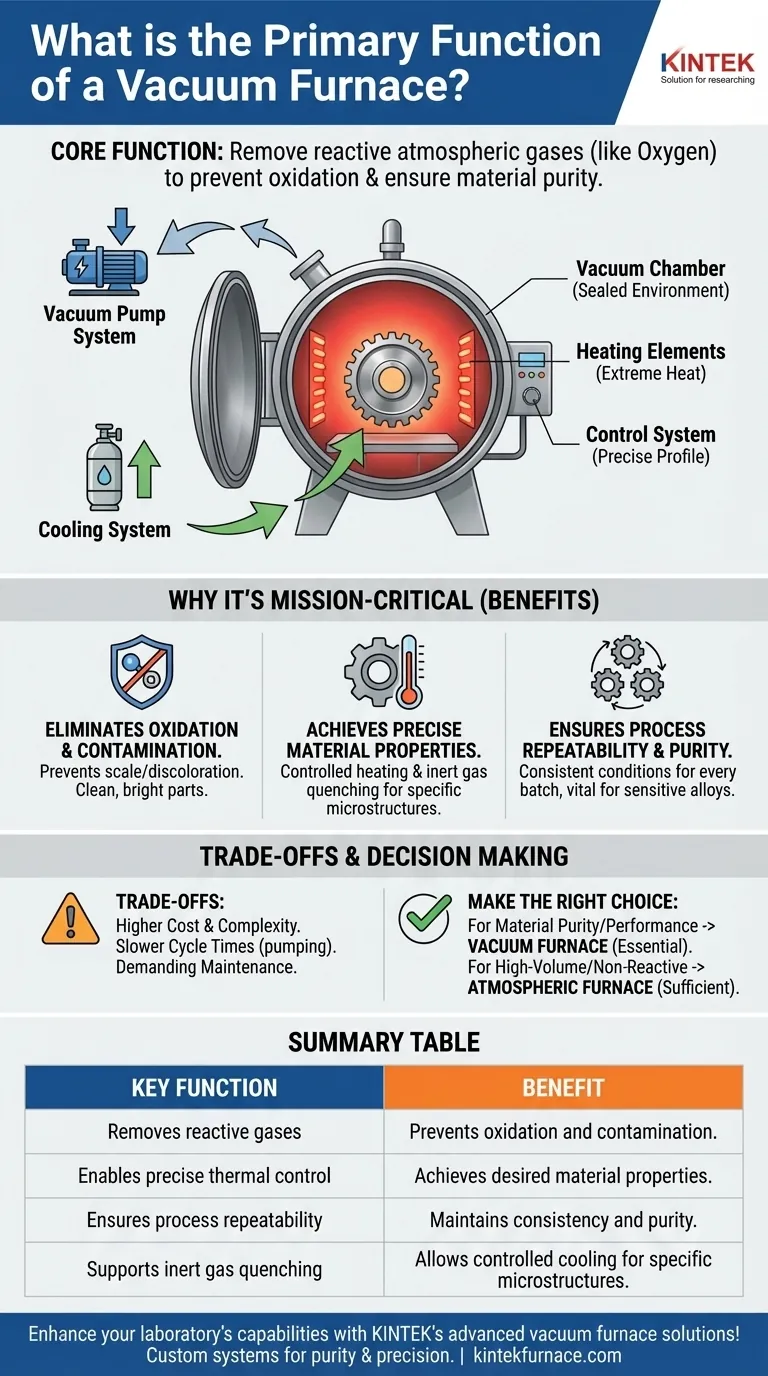

At its core, a vacuum furnace is a highly specialized oven designed to heat materials, typically metals, to extreme temperatures within a controlled, low-pressure environment. Its primary function is to remove reactive atmospheric gases, like oxygen, from the heating chamber. This prevents unwanted chemical reactions, chiefly oxidation, ensuring the material's integrity and purity are maintained throughout the process.

The essential purpose of a vacuum furnace is not merely to heat materials, but to create an exceptionally clean environment. By removing the atmosphere, it eliminates the risk of oxidation and contamination, enabling the production of higher-quality components with superior material properties.

Why a Vacuum is Mission-Critical for Heat Treatment

Using a vacuum is a deliberate choice to solve specific problems that arise when heating reactive materials in a normal air atmosphere. It fundamentally changes the outcome of the heat-treating process.

Eliminating Oxidation and Contamination

When metals are heated in the presence of oxygen, they oxidize, forming a layer of scale or discoloration on the surface. This oxidation can alter the dimensions of a part, compromise its surface finish, and weaken its structural integrity.

A vacuum furnace physically removes the vast majority of air and other gases from the chamber before heating begins. This starves the process of the oxygen required for these destructive reactions to occur.

The result is a bright, clean part that requires little to no post-process cleaning, preserving its precise specifications and material purity.

Achieving Precise Material Properties

Heat treatment is not just about heating; it is about the entire thermal cycle, including cooling. A vacuum furnace offers unparalleled control over this entire process.

The integrated cooling system, often using inert gas quenching, allows for precisely managed cooling rates. This control is critical for developing specific microstructures within the metal, which in turn determines final properties like hardness, ductility, and strength.

Ensuring Process Repeatability and Purity

By operating in a sealed, controlled environment, a vacuum furnace ensures that every batch is processed under the exact same conditions. This level of consistency is vital for industries where even minor variations are unacceptable.

For processes like vacuum sintering, where fine metal powders are fused into a solid mass, a vacuum is essential. It prevents the particles from oxidizing, which would inhibit proper bonding and lead to a defective final part.

Deconstructing the Vacuum Furnace System

A vacuum furnace is a complex system where several key components work in unison to create the ideal processing environment.

The Vacuum Chamber and Pump System

The vacuum chamber is the sealed vessel that contains the workpiece. It is built to withstand both extreme temperatures and the pressure differential between the inside and outside.

The vacuum system, composed of one or more pumps, is the heart of the operation. Its job is to evacuate air from the chamber to achieve the required low-pressure (vacuum) level and maintain it during the cycle.

The Heating and Control Systems

Heating elements, typically made of graphite or refractory metals, generate the intense heat required for the process.

A sophisticated temperature control system precisely manages the rate of heating, the holding time at a specific temperature, and the initiation of the cooling cycle. This ensures the material undergoes the exact thermal profile needed for the desired outcome.

The Integrated Cooling System

After the heating phase, the cooling system takes over. This system rapidly introduces a high-purity inert gas, like nitrogen or argon, into the chamber to cool the workpiece at a controlled rate, a process known as gas quenching.

Understanding the Trade-offs

While powerful, vacuum furnaces are not the solution for every application. Understanding their limitations is key to making an informed decision.

Higher Initial Cost and Complexity

Vacuum furnaces represent a significant capital investment compared to conventional atmospheric furnaces. Their complex pump systems, seals, and control instrumentation also require a higher level of technical expertise to operate and maintain.

Potentially Slower Cycle Times

The process of pumping the chamber down to the required vacuum level adds time to each cycle. For high-volume production of simple parts, this can make vacuum processing slower than continuous atmospheric furnace operations.

Demanding Maintenance Requirements

The integrity of the vacuum system is paramount. Seals, gaskets, and pumps require regular, specialized maintenance to prevent leaks and ensure the furnace can consistently reach and hold the target vacuum level.

Making the Right Choice for Your Goal

Your decision to use a vacuum furnace versus a conventional furnace should be driven entirely by the required quality and properties of the final product.

- If your primary focus is material purity and performance: A vacuum furnace is non-negotiable for eliminating oxidation and achieving specific metallurgical properties in reactive metals.

- If your primary focus is creating complex alloys or sintered parts: The pristine, controlled environment of a vacuum furnace is essential for ensuring process repeatability and preventing defects.

- If your primary focus is high-volume, low-cost processing of non-reactive materials: A conventional atmospheric furnace may be a more efficient and cost-effective solution where surface oxidation is not a critical concern.

Understanding this core function empowers you to select the precise manufacturing process that meets your standards for quality, performance, and reliability.

Summary Table:

| Key Function | Benefit |

|---|---|

| Removes reactive gases | Prevents oxidation and contamination |

| Enables precise thermal control | Achieves desired material properties like hardness and strength |

| Ensures process repeatability | Maintains consistency and purity in production |

| Supports inert gas quenching | Allows controlled cooling for specific microstructures |

Enhance your laboratory's capabilities with KINTEK's advanced vacuum furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements for purity, precision, and repeatability. Contact us today to discuss how our tailored solutions can optimize your heat treatment processes and deliver superior results!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today