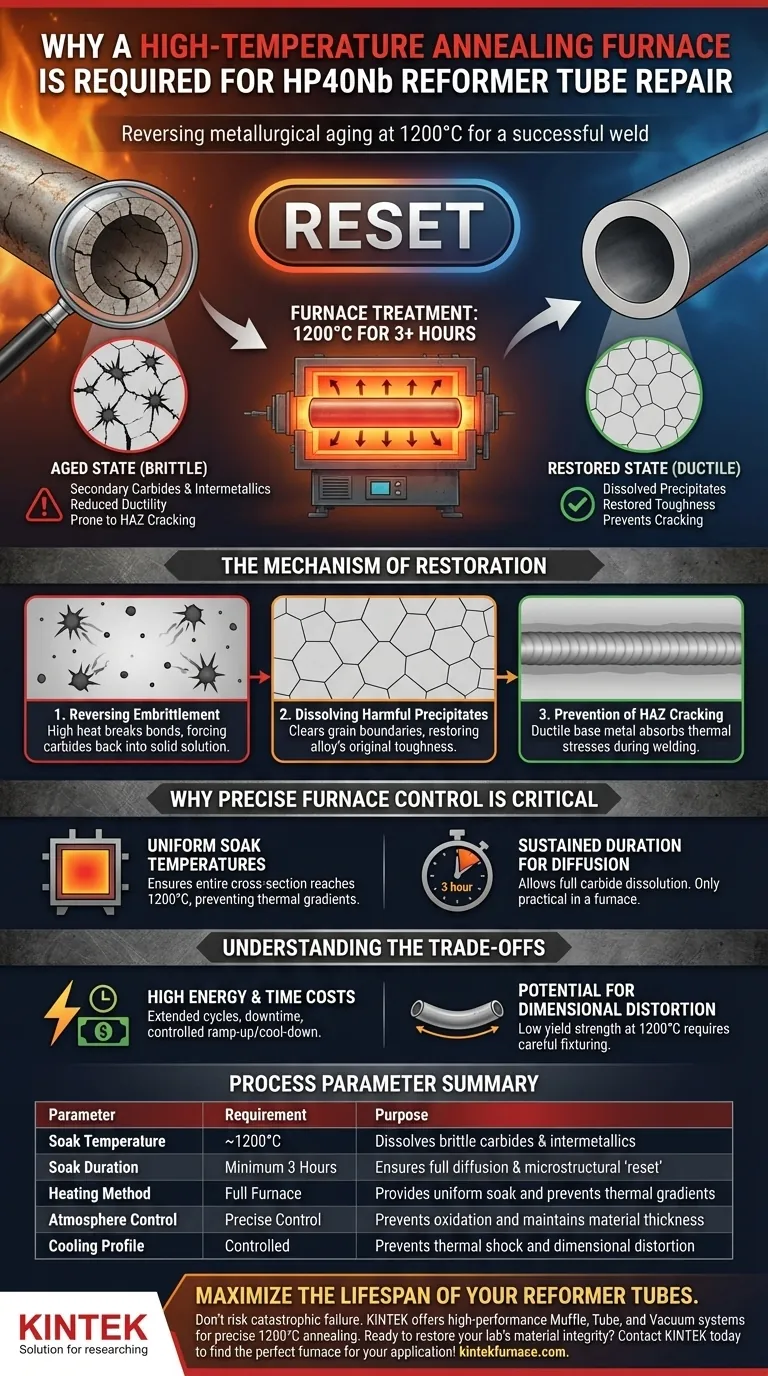

A high-temperature annealing furnace is strictly required to reverse the metallurgical aging that occurs in HP40Nb reformer tubes during long-term service. By sustaining a precise temperature of approximately 1200°C for at least 3 hours, the furnace dissolves brittle secondary carbides and intermetallic compounds back into the metal matrix, restoring the ductility necessary for a successful repair.

Core Insight: The annealing furnace functions as a microstructural "reset button." It transforms the material from a brittle, aged state—prone to immediate cracking during welding—back to a ductile state that closely mimics the alloy's original manufacturing condition.

The Mechanism of Microstructural Restoration

To understand the necessity of the furnace, you must first understand the degradation of the material. The following sections detail why this thermal intervention is non-negotiable.

Reversing Service-Induced Embrittlement

During their service life, HP40Nb tubes are exposed to extreme heat and pressure. This causes carbon and other elements to precipitate out of the solid solution, forming secondary carbides and intermetallic compounds.

These precipitates accumulate at the grain boundaries, significantly reducing the ductility of the alloy. Without treatment, the material becomes brittle and incapable of withstanding the thermal expansion and contraction stresses inherent in welding.

Dissolving Harmful Precipitates

The solid solution treatment relies on specific thermodynamic principles. The furnace provides the energy required to break the bonds of the precipitated carbides.

By holding the material at 1200°C, the furnace forces these precipitates to dissolve back into the austenitic matrix. This process effectively clears the grain boundaries of brittle phases, restoring the alloy's toughness.

Prevention of Heat-Affected Zone (HAZ) Cracking

The most critical risk in repairing reformer tubes is cracking in the Heat-Affected Zone (HAZ) adjacent to the weld.

If the base metal remains brittle, the heat from the welding arc will induce stress fractures in the HAZ. The annealing process ensures the base metal is ductile enough to absorb these thermal stresses without failing, ensuring the structural integrity of the repair.

Why Precise Furnace Control is Critical

You cannot achieve this result with localized heating methods like torches or heating pads. The furnace environment offers specific advantages required for this metallurgy.

Achieving Uniform Soak Temperatures

The dissolution of carbides requires the entire cross-section of the tube to reach 1200°C.

A furnace ensures that the temperature is uniform throughout the component, preventing thermal gradients that could introduce new stresses or result in only partial treatment of the material.

Sustained Duration for Diffusion

Time is as critical as temperature. The primary reference notes a requirement of 3 hours at peak temperature.

This duration allows sufficient time for the diffusion of atoms, ensuring the carbides are fully dissolved. A furnace is the only practical way to maintain such high temperatures consistently for this duration.

Understanding the Trade-offs

While solid solution annealing is technically superior, it presents logistical challenges that must be managed.

High Energy and Time Costs

Running a furnace at 1200°C for extended cycles is energy-intensive and time-consuming.

It requires significant downtime for the equipment, not just for the 3-hour soak, but for the controlled ramp-up and cool-down periods required to prevent thermal shock.

Potential for Dimensional Distortion

At 1200°C, the metal's yield strength is very low.

There is a risk that the tubes may sag or distort under their own weight if not properly supported within the furnace. Fixturing must be carefully designed to maintain dimensional tolerances during the treatment.

Making the Right Choice for Your Repair Strategy

The decision to use a high-temperature annealing furnace is driven by the need for safety and longevity over speed.

- If your primary focus is Long-Term Reliability: Prioritize the full 3-hour soak at 1200°C to maximize ductility and eliminate the risk of delayed cracking in service.

- If your primary focus is Weld Integrity: Ensure the furnace utilized has calibrated thermal controls to guarantee the entire component reaches the solutionizing temperature, preventing weak spots in the HAZ.

The high-temperature annealing furnace is the only reliable method to guarantee that a repaired HP40Nb tube will not fail prematurely due to remnant brittleness.

Summary Table:

| Process Parameter | Requirement | Purpose in HP40Nb Restoration |

|---|---|---|

| Soak Temperature | ~1200°C | Dissolves brittle secondary carbides & intermetallics |

| Soak Duration | Minimum 3 Hours | Ensures full diffusion & microstructural 'reset' |

| Heating Method | Full Furnace | Provides uniform soak and prevents thermal gradients |

| Atmosphere Control | Precise Control | Prevents oxidation and maintains material thickness |

| Cooling Profile | Controlled | Prevents thermal shock and dimensional distortion |

Maximize the Lifespan of Your Reformer Tubes

Don't risk catastrophic failure during repair welding. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, and Vacuum systems—all customizable for your specific high-temperature annealing needs. Our precision thermal solutions ensure your HP40Nb tubes achieve the exact 1200°C profile required for successful microstructural restoration.

Ready to restore your lab’s material integrity? Contact KINTEK today to find the perfect furnace for your application!

Visual Guide

References

- Matías H. Sosa Lissarrague, César A. Lanz. Heat resistant Ni-Cr-Fe austenitic alloys for pyrolysis furnaces: A review. DOI: 10.3989/revmetalm.e274.1678

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How does an annealing furnace achieve uniform temperature distribution? Master Heat Treatment Consistency

- What are the key features of laboratory vacuum furnaces? Unlock Pure, Controlled High-Temp Processing

- How does a high-purity argon environment impact the operation of a sintering furnace? Achieve 316L Electrode Excellence

- What is a vacuum furnace and how does it differ from an atmosphere furnace? Choose the Right Heat Treatment for Your Lab

- What are the advantages of vacuum heat treatment furnaces? Achieve Superior Process Control and Purity

- What temperature range can vacuum furnaces achieve? Unlock High-Temp Precision for Your Lab

- What is the key function of the internal water-cooled condensation crystallization disc in a vacuum sublimation furnace? Master Metal Purification

- What are drop-bottom quench furnaces used for? Achieve Rapid Quenching for High-Performance Alloys