At their core, vacuum heat treatment furnaces provide superior process control and material outcomes by creating an exceptionally pure operating environment. This prevents unwanted reactions like oxidation and decarburization, ensures precise temperature uniformity, and results in components with a clean surface finish, enhanced mechanical properties, and high repeatability from batch to batch.

The fundamental advantage of a vacuum furnace is not merely the absence of air, but the creation of a highly controlled environment. This control allows you to dictate the final properties of a material with a precision that is often unattainable in traditional atmosphere furnaces.

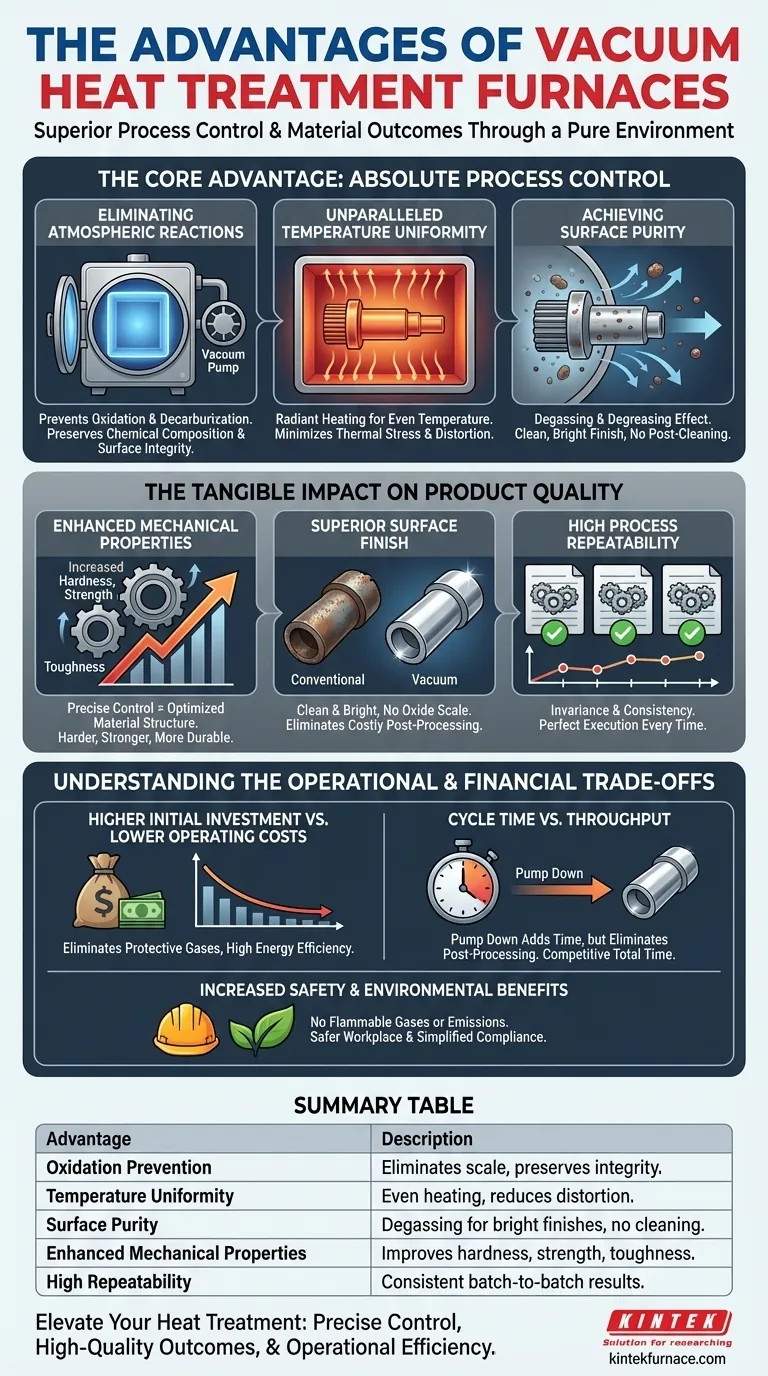

The Core Advantage: Absolute Process Control

Choosing a vacuum furnace is about taking command of the metallurgical variables that define product quality. It transforms heat treatment from a reactive process into a highly prescriptive one.

Eliminating Atmospheric Reactions

In a conventional furnace, the material's hot surface reacts with gases in the air, primarily oxygen. A vacuum furnace removes this variable entirely.

This prevents oxidation, the formation of scale on the part's surface. It also stops decarburization, which is the loss of carbon from the surface of steel, a reaction that makes the material softer and weaker.

By eliminating these reactions, the material's original chemical composition and surface integrity are preserved without the need for expensive or flammable protective gases like argon or hydrogen.

Unparalleled Temperature Uniformity

A vacuum is an excellent insulator. In a vacuum furnace, heat is transferred primarily through radiation, not convection.

This method allows for extremely uniform heating, ensuring the entire workpiece, including complex geometries, reaches the target temperature at the same rate. This minimizes thermal stress and reduces the risk of distortion or cracking.

This precise temperature control, combined with controlled cooling rates, is critical for achieving the desired metallurgical microstructure and, consequently, the final material properties.

Achieving Surface Purity

The vacuum actively pulls volatile elements and contaminants off the workpiece surface as it heats up.

This process provides a degassing and degreasing effect, removing contaminants like surface oils or dissolved gases like hydrogen. This is particularly important for preventing hydrogen embrittlement in sensitive alloys.

The result is an exceptionally clean, bright surface finish that often requires no subsequent cleaning or finishing operations, reducing process steps and costs.

The Tangible Impact on Product Quality

The process control inherent to vacuum treatment translates directly into measurable improvements in the final product.

Enhanced Mechanical Properties

Because the heating and cooling cycles are so precisely controlled and uniform, you can achieve more consistent and optimized material structures.

This leads to significant improvements in hardness, strength, and toughness. The process delivers a high-performance part that is more durable and has a longer service life.

Superior Surface Finish

Parts emerge from a vacuum furnace clean and bright, free of the oxide scale that is typical of conventional heat treatment.

This not only improves the aesthetic of the part but also eliminates the need for costly and abrasive post-processing steps like sandblasting or acid pickling.

High Process Repeatability

Once a heating and cooling profile is established, a vacuum furnace can execute it perfectly time and again.

This invariance and repeatability ensure that every part in a batch, and every subsequent batch, receives the exact same treatment. This leads to a very high product pass rate and exceptional quality consistency, which is critical for industries like aerospace and medical devices.

Understanding the Operational and Financial Trade-offs

While the advantages are significant, a complete picture requires understanding the practical considerations of adopting vacuum technology.

Higher Initial Investment vs. Lower Operating Costs

Vacuum furnaces typically represent a higher upfront capital investment compared to standard atmosphere furnaces.

However, this is often offset by lower operating costs over the equipment's lifespan. You eliminate the continuous expense of purchasing, storing, and handling protective atmosphere gases. The high energy efficiency of vacuum furnaces also contributes to long-term savings.

Cycle Time Considerations

The need to pump down the chamber to create a vacuum adds time to the beginning of each cycle. For some very high-volume, low-margin parts, a continuous atmosphere furnace may offer higher throughput.

This trade-off must be weighed against the potential elimination of post-processing steps, which could make the total "part-in to part-out" time for vacuum treatment more competitive than it first appears.

Increased Safety and Environmental Benefits

Eliminating flammable or asphyxiant gases dramatically improves workplace safety. There is no risk of explosions associated with hydrogen or the hazards of managing large volumes of inert gas.

Furthermore, vacuum furnaces produce no harmful emissions, making them an environmentally friendly choice that simplifies compliance with regulations.

Applying This to Your Heat Treatment Goals

The decision to use a vacuum furnace should be directly linked to your final product requirements and operational priorities.

- If your primary focus is maximum performance and purity: Vacuum treatment is the definitive choice for critical components in aerospace, medical, or high-end tooling where material properties are non-negotiable.

- If your primary focus is process consistency and quality: Vacuum furnaces provide unmatched repeatability, making them ideal for any application where reducing part-to-part variation is a key goal.

- If your primary focus is operational safety and reduced running costs: The elimination of atmosphere gases makes vacuum furnaces a safer and often more cost-effective long-term solution, despite a higher initial investment.

Ultimately, adopting vacuum heat treatment is an investment in control, consistency, and quality.

Summary Table:

| Advantage | Description |

|---|---|

| Oxidation Prevention | Eliminates surface scale by removing oxygen, preserving material integrity. |

| Temperature Uniformity | Uses radiation for even heating, reducing thermal stress and distortion. |

| Surface Purity | Provides degassing and cleaning, resulting in bright finishes without post-processing. |

| Enhanced Mechanical Properties | Improves hardness, strength, and toughness through precise control. |

| High Repeatability | Ensures consistent batch-to-batch results for reliable quality. |

Ready to elevate your heat treatment with precise control and high-quality outcomes? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Vacuum & Atmosphere Furnaces, Muffle, Tube, Rotary Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs, delivering enhanced mechanical properties, superior surface finishes, and operational efficiency. Contact us today to discuss how our tailored solutions can benefit your laboratory!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision