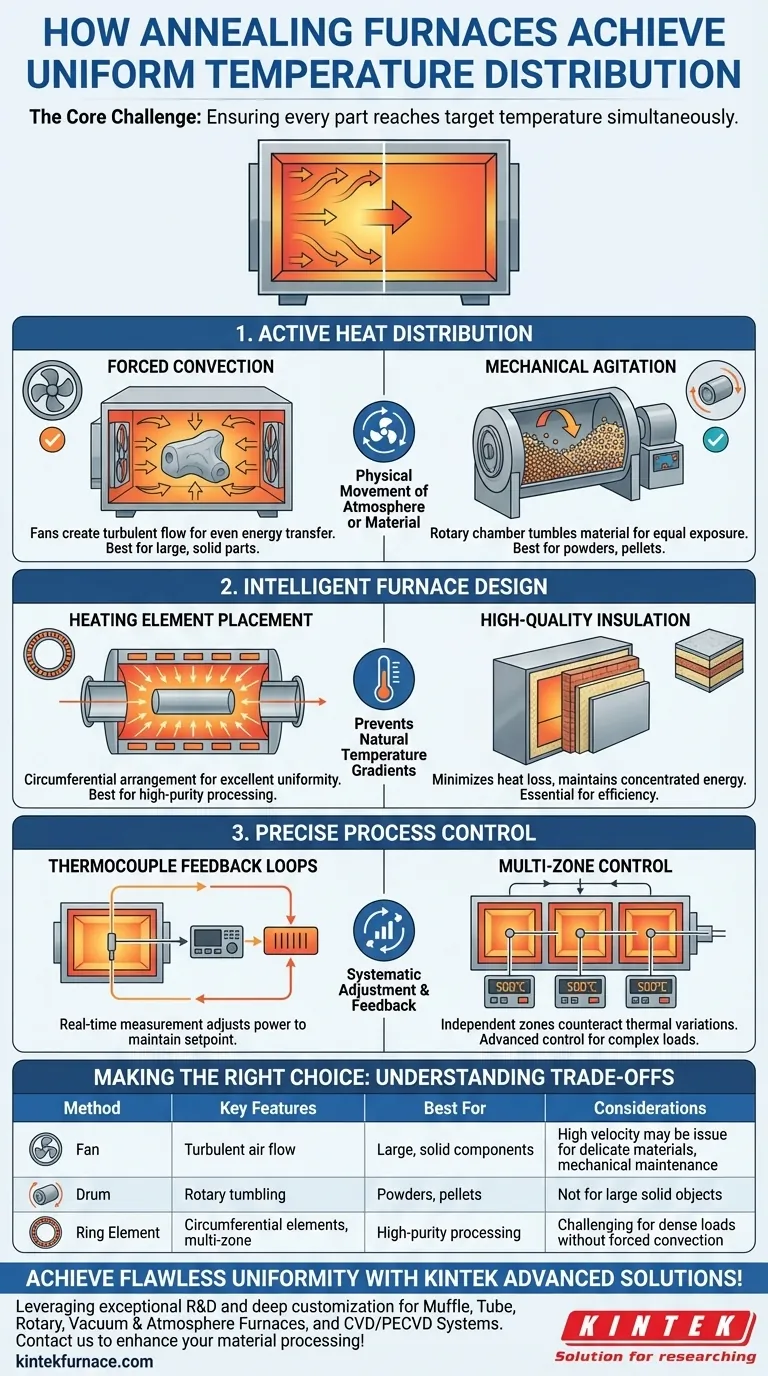

Achieving perfect temperature uniformity is the central design goal of any high-performance annealing furnace. The most common method involves using powerful internal circulation fans to force hot air throughout the chamber, eliminating hot and cold spots. However, this is just one of several engineering principles used, with the specific method depending on the furnace's design and intended application.

The core challenge in annealing is not just reaching a target temperature, but ensuring every part of the material reaches that temperature simultaneously. This is achieved through a combination of three key strategies: active heat distribution, intelligent furnace design, and precise process control.

The Core Principles of Thermal Uniformity

True uniformity is a result of a system working in concert. Understanding the principles behind the hardware allows you to better diagnose issues and select the right equipment for a given process.

Principle 1: Active Heat Distribution

This involves physically moving either the heated atmosphere or the material itself.

- Forced Convection: In many standard box or bell-type annealing furnaces, one or more high-volume fans are used. These fans create a continuous, turbulent flow of the heated atmosphere, ensuring it transfers energy evenly to all surfaces of the workload.

- Mechanical Agitation: For materials like powders or pellets, a rotary furnace is used. The entire chamber rotates, causing the material to tumble and mix continuously. This ensures every particle is equally exposed to the heat source.

Principle 2: Intelligent Furnace Design

The physical construction of the furnace plays a critical role in preventing natural temperature gradients.

- Heating Element Placement: In tube furnaces, heating elements are often arranged circumferentially around the processing tube. This design radiates heat inward from all directions, providing excellent uniformity for the workload inside.

- High-Quality Insulation: Modern insulation materials minimize heat loss to the outside environment. This keeps thermal energy concentrated within the chamber, reducing the power required to maintain temperature and minimizing cold spots near the furnace walls.

Principle 3: Precise Process Control

A furnace is only as uniform as its control system allows it to be.

- Thermocouple Feedback Loops: Furnaces use multiple thermocouples placed in strategic locations to measure the real-time temperature. This data is fed back to a controller, which constantly adjusts the power output to the heating elements to maintain the precise temperature setpoint across the entire chamber.

- Multi-Zone Control: More advanced furnaces divide the heating elements into several independent "zones." Each zone has its own thermocouple and control loop, allowing the system to direct more or less heat to specific areas as needed to counteract thermal variations.

Understanding the Trade-offs

No single method is perfect for every application. The choice of furnace design involves balancing performance, cost, and material compatibility.

Convection Fans

Fans are excellent for creating uniformity in large, open chambers with bulky or irregularly shaped parts. However, the high-velocity air can be a problem for fine powders or delicate materials, potentially causing contamination. The fans are also mechanical components that require maintenance and can be a point of failure.

Rotary Agitation

Rotation is the most effective method for ensuring uniform heating of granular materials. It is far superior to forced air for these applications. Its primary limitation is that it can only be used for materials that can be tumbled, making it unsuitable for large, solid objects or assembled components.

Static Heating Elements

A well-designed tube or muffle furnace with strategically placed elements offers high reliability and purity, as there are no moving parts like fans inside the heating chamber. However, in larger chambers without forced convection, achieving uniformity for a densely packed or large-volume load can be more challenging.

Making the Right Choice for Your Goal

The optimal method for achieving temperature uniformity is directly tied to the material you are processing and your desired outcome.

- If your primary focus is processing large, solid components: A convection furnace with powerful circulation fans is your most reliable solution for driving heat evenly into the material's core.

- If your primary focus is treating powders, pellets, or granular materials: A rotary furnace is superior, as its mechanical agitation provides a level of uniformity that forced air cannot match.

- If your primary focus is high-purity processing in a controlled atmosphere: A tube furnace with multi-zone, strategically placed heating elements and precise thermocouple feedback offers the best control without introducing potential contaminants.

Ultimately, understanding these mechanisms empowers you to select and operate your furnace to achieve perfectly consistent and repeatable material properties.

Summary Table:

| Method | Key Features | Best For |

|---|---|---|

| Forced Convection | High-volume fans for turbulent air flow | Large, solid components |

| Mechanical Agitation | Rotary chamber for tumbling materials | Powders, pellets, granular materials |

| Static Heating Elements | Circumferential elements, multi-zone control | High-purity processing in controlled atmospheres |

Achieve flawless temperature uniformity in your lab with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs. Contact us today to enhance your material processing efficiency and consistency!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- What does inert mean in furnace atmospheres? Protect materials from oxidation with inert gases.

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- What are the environmental benefits of using inert gases in furnaces? Reduce Waste and Emissions for a Greener Process

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment