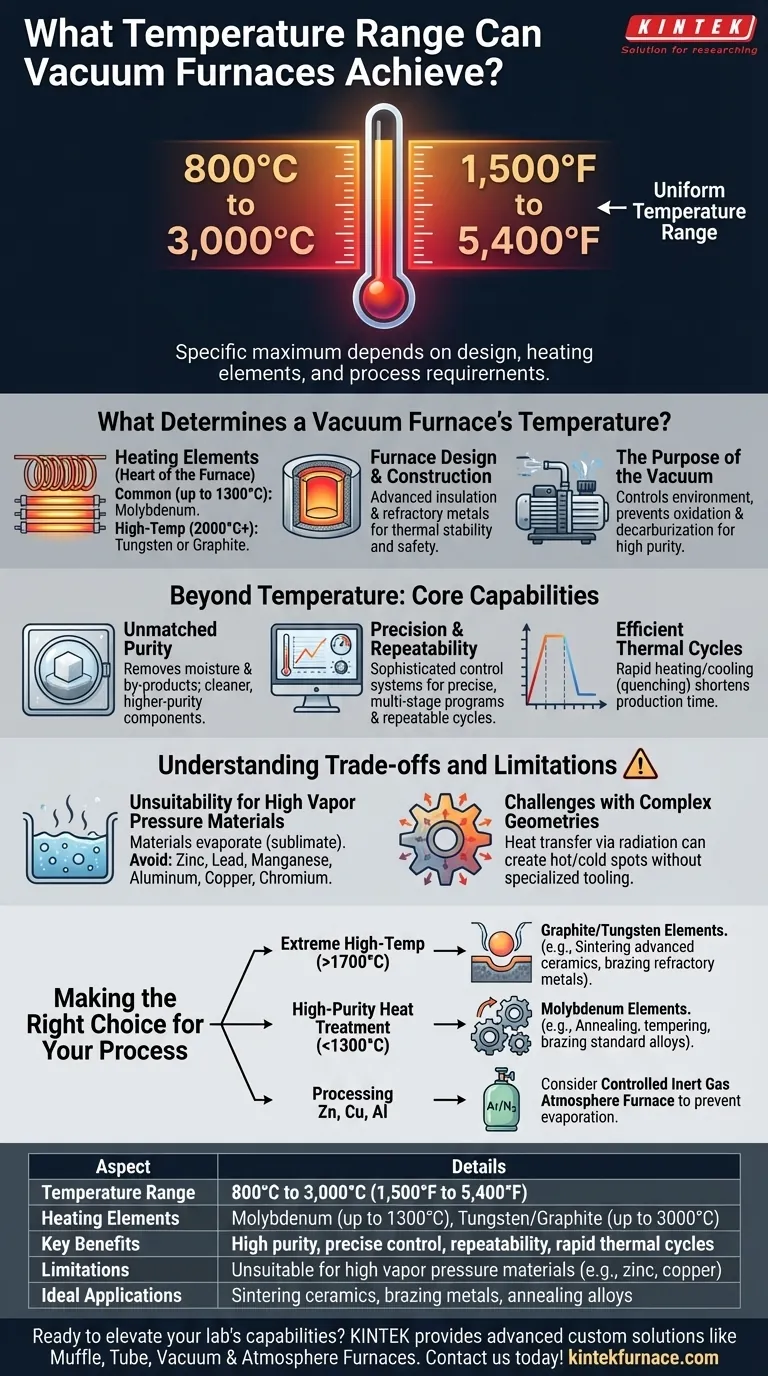

In short, a vacuum furnace can achieve a uniform temperature range from approximately 800°C up to 3,000°C (1,500°F to 5,400°F). However, the specific maximum temperature of any given furnace is determined by its design, the materials used for its heating elements, and the requirements of the process it is built for.

The true value of a vacuum furnace isn't just its high temperature, but its ability to apply that heat with extreme precision in an environment free of contaminants. Understanding this distinction is the key to leveraging its full potential.

What Determines a Vacuum Furnace's Temperature?

The broad temperature range of vacuum furnaces is a direct result of their specialized construction. Not all furnaces are designed to reach the highest possible temperatures, as different applications have vastly different thermal requirements.

The Role of Heating Elements

The heart of the furnace is its heating element, and its material composition dictates the peak operating temperature. Common furnaces for applications up to 1300°C often use molybdenum, while reaching temperatures of 2000°C and beyond requires more exotic elements like tungsten or graphite.

Furnace Design and Construction

The furnace's internal chamber, insulation, and overall structure must be able to withstand the target temperatures. High-temperature models use advanced insulation and refractory metals to ensure thermal stability, balance the temperature field, and maintain a low external surface temperature for safety and efficiency.

The Purpose of the Vacuum

The vacuum itself is not for generating heat but for controlling the environment. By removing atmospheric gases, the furnace prevents oxidation, decarburization, and other unwanted chemical reactions on the material's surface, ensuring a high-purity final product.

Beyond Temperature: Core Capabilities

The decision to use a vacuum furnace is rarely about heat alone. It's about achieving a level of quality and control that is impossible in a standard atmosphere.

Unmatched Purity and Cleanliness

By operating under vacuum, the process actively removes moisture, binders, and other by-products as the material is heated. This outgassing results in a cleaner, higher-purity component with superior material properties.

Precision and Repeatability

Modern vacuum furnaces are managed by sophisticated computer control systems. These systems allow for precise, multi-stage temperature programs, fine control over vacuum levels, and repeatable cycles, ensuring that every part is processed under identical conditions.

Efficient Thermal Cycles

Many vacuum furnaces are engineered for rapid heating and cooling. This capability, often referred to as quenching, is critical for specific heat treatment processes like hardening and can significantly shorten overall production time.

Understanding the Trade-offs and Limitations

Despite their power, vacuum furnaces are not a universal solution. Their unique operating principles create specific constraints that make them unsuitable for certain applications.

Unsuitability for High Vapor Pressure Materials

This is the most critical limitation. Materials with a high saturated vapor pressure will begin to evaporate, or "boil," under vacuum at high temperatures. This phenomenon, known as outgassing or sublimation, can alter the surface chemistry and composition of the workpiece.

Materials to avoid in high-temp vacuum processes include zinc, lead, manganese, aluminum, copper, and chromium.

Challenges with Complex Geometries

Achieving perfect temperature uniformity across a large or intricately shaped workpiece can be difficult. The absence of air for convection means heat is transferred primarily through radiation, which can create hot or cold spots without specialized tooling and careful process design.

Making the Right Choice for Your Process

Selecting the right thermal solution requires matching your material and desired outcome to the furnace's capabilities.

- If your primary focus is extreme high-temperature processing (>1700°C): You need a specialized furnace with graphite or tungsten elements designed for applications like sintering advanced ceramics or brazing refractory metals.

- If your primary focus is high-purity heat treatment of standard alloys (<1300°C): A common vacuum furnace with molybdenum elements provides an excellent balance of performance for processes like annealing, tempering, and brazing.

- If your primary focus is processing materials like zinc, copper, or aluminum: A vacuum furnace is likely the wrong tool; consider a furnace that uses a controlled inert gas atmosphere (like argon or nitrogen) to prevent both oxidation and material evaporation.

Ultimately, choosing the right furnace begins with a deep understanding of your material's behavior under heat and vacuum.

Summary Table:

| Aspect | Details |

|---|---|

| Temperature Range | 800°C to 3,000°C (1,500°F to 5,400°F) |

| Heating Elements | Molybdenum (up to 1300°C), Tungsten/Graphite (up to 3000°C) |

| Key Benefits | High purity, precise control, repeatability, rapid thermal cycles |

| Limitations | Unsuitable for high vapor pressure materials (e.g., zinc, copper) |

| Ideal Applications | Sintering ceramics, brazing metals, annealing alloys |

Ready to elevate your lab's capabilities with a custom high-temperature furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization ensures your unique experimental needs are met with precision and reliability. Contact us today to discuss how our furnaces can enhance your research and production processes!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- How do vacuum sintering and annealing furnaces contribute to the densification of NdFeB magnets?

- What role does a vacuum hot pressing furnace play in TiBw/TA15 synthesis? Enhance In-Situ Composite Performance

- What is the mechanism of a vacuum sintering furnace for AlCoCrFeNi2.1 + Y2O3? Optimize Your High-Entropy Alloy Processing

- Why is a vacuum hot press sintering furnace required for nanocrystalline ceramics? Preserve Structure with Pressure

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness