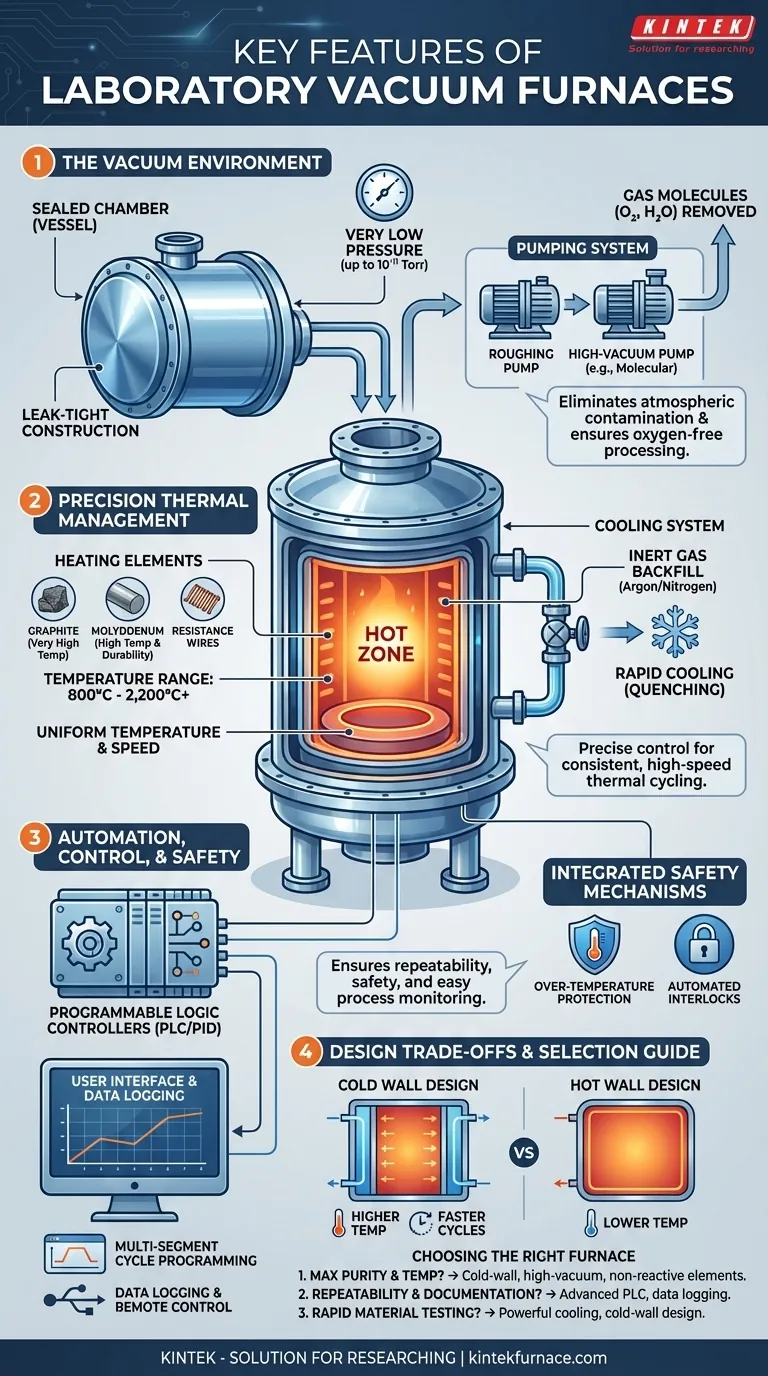

The defining features of a laboratory vacuum furnace center on its ability to create an extremely pure, controlled, oxygen-free environment for high-temperature material processing. This is accomplished through an integrated system comprising a sealed chamber, a high-performance vacuum pump system, precision heating elements, and sophisticated programmable controls that ensure safety and repeatability.

A laboratory vacuum furnace is more than just an oven; it is a precision instrument. Its key features are not standalone components but an interconnected system designed to eliminate atmospheric contamination and provide absolute control over the thermal cycle, enabling material transformations that are impossible in a standard furnace.

The Foundation: The Vacuum Environment

The primary function of the furnace is to remove the atmosphere—primarily oxygen and water vapor—which would otherwise react with materials at high temperatures. This is achieved through two core components.

The Vacuum Chamber (Vessel)

The furnace body itself is a sealed vessel, typically constructed from stainless steel or other durable alloys. This chamber is engineered to be leak-tight and withstand the immense pressure differential between the internal vacuum and the external atmosphere.

The Pumping System

This system actively removes gas molecules from the chamber. It often consists of multiple pumps working in stages, such as a mechanical "roughing" pump and a high-vacuum pump (like a molecular or eddy current pump), to achieve exceptionally low pressures, sometimes as low as 1×10⁻¹¹ Torr.

The Engine: Precision Thermal Management

Once the vacuum is established, the thermal system takes over. Its features are designed for uniformity, speed, and precise control over a wide temperature range, often from 800°C to over 2,200°C.

The Hot Zone and Heating Elements

The "hot zone" is the insulated interior where heating occurs. Heating elements are chosen based on the required temperature and chemical compatibility. Common materials include graphite, molybdenum, or resistance wires, each with a different maximum operating temperature.

The design of these elements is critical for ensuring uniform temperature throughout the workload, which prevents inconsistencies in the final product.

The Cooling System

A key feature is the ability to cool materials quickly and in a controlled manner, often by backfilling the chamber with an inert gas like argon or nitrogen. This rapid cooling, or quenching, can be crucial for locking in specific metallurgical properties.

The Brain: Automation, Control, and Safety

For research and laboratory applications, repeatability and safety are non-negotiable. Modern vacuum furnaces integrate advanced control systems to manage the entire process without manual intervention.

Programmable Logic Controllers (PLC/PID)

These controllers are the heart of the furnace's automation. Researchers can program complex, multi-segment cycles that specify heating rates, temperature "dwell" times, and cooling profiles. This ensures every run is identical.

User Interface and Data Logging

Most lab furnaces feature a touchscreen interface for easy parameter adjustment and process monitoring. Optional PC integration allows for remote control and, critically, data logging of the entire process for analysis, quality control, and publication.

Integrated Safety Mechanisms

Given the extreme temperatures and pressures involved, safety is paramount. Features include over-temperature protection, which shuts down the system if it exceeds a set limit, and automated interlocks that prevent the door from being opened under unsafe conditions.

Understanding Key Design Trade-offs

Not all vacuum furnaces are the same. The specific features are driven by design choices that involve important trade-offs.

Cold Wall vs. Hot Wall Design

This is a fundamental distinction. Cold wall furnaces, where the heating elements are inside the vacuum chamber and the vessel walls are water-cooled, are more common in labs. They allow for much higher temperatures, faster heating/cooling cycles, and better temperature uniformity.

Hot wall designs, where the entire chamber is placed inside a larger furnace, are generally limited to lower temperatures.

Material Selection

The choice of materials for the hot zone and heating elements is a critical trade-off. Graphite is excellent for very high temperatures but can be reactive with certain materials. Molybdenum offers a good balance of high-temperature performance and durability. This choice directly impacts the furnace's cost and application range.

Making the Right Choice for Your Goal

Selecting a furnace requires matching its features to your specific research or application needs.

- If your primary focus is maximum purity and temperature: Prioritize a cold-wall design with a multi-stage, high-vacuum pumping system and non-reactive heating elements like molybdenum or tungsten.

- If your primary focus is process repeatability and documentation: The sophistication of the programmable controller (PLC) and its data logging and remote-control capabilities are your most important features.

- If your primary focus is rapid material property testing: Look for a furnace with a powerful cooling system and a cold-wall design to enable the fastest possible thermal cycles.

Ultimately, these integrated features empower you to precisely manipulate a material's structure and purity in a controlled and repeatable way.

Summary Table:

| Feature Category | Key Components | Benefits |

|---|---|---|

| Vacuum Environment | Sealed chamber, multi-stage pumps | Eliminates atmospheric contamination, enables oxygen-free processing |

| Precision Thermal Management | Heating elements (graphite, molybdenum), cooling system | Uniform heating, rapid cooling, wide temperature range (800°C to 2,200°C+) |

| Automation & Control | PLC/PID controllers, user interface, data logging | Ensures repeatability, safety, and easy process monitoring |

| Safety Mechanisms | Over-temperature protection, automated interlocks | Prevents accidents, enhances operational security |

Ready to elevate your lab's capabilities with a customized vacuum furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature solutions. Our product line, including Vacuum & Atmosphere Furnaces, CVD/PECVD Systems, Muffle, Tube, and Rotary Furnaces, is backed by strong deep customization to meet your unique experimental needs. Contact us today to discuss how we can help you achieve precise, contamination-free material processing!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today