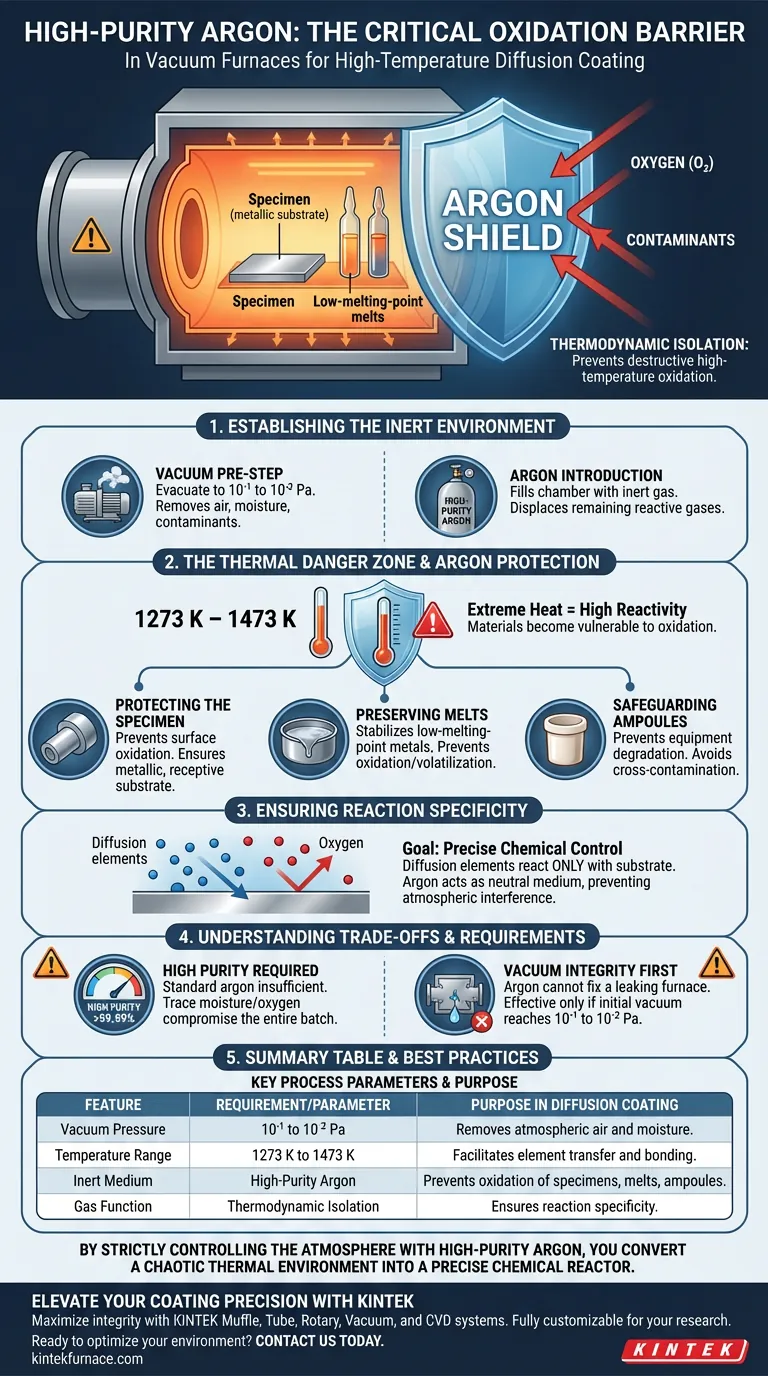

High-purity argon serves as a critical barrier against high-temperature oxidation during the diffusion coating process.

Once the furnace chamber is evacuated to a residual pressure of 10⁻¹ to 10⁻² Pa, introducing argon establishes a completely inert environment. This protective atmosphere is essential at operating temperatures between 1273 K and 1473 K to prevent oxygen from reacting with the specimens, molten metals, or equipment, ensuring the diffusion chemistry remains pure.

Core Takeaway The introduction of high-purity argon is not merely about filling space; it is about thermodynamic isolation. By displacing reactive gases, argon ensures that chemical reactions occur exclusively between the diffusion elements and the substrate, preventing the destructive oxidation that inevitably occurs in high-heat environments.

Establishing the Inert Environment

The Vacuum Pre-step

Before argon is introduced, the system must undergo a vacuum process.

The chamber is evacuated to a residual pressure of 10⁻¹ to 10⁻² Pa.

This step removes the bulk of atmospheric air, moisture, and contaminants that would otherwise contaminate the coating process.

The Thermal Danger Zone

Diffusion coating typically requires extreme heat, specifically ranging from 1273 K to 1473 K.

At these temperatures, materials become highly reactive.

Without an inert gas shield, the substrate and coating materials would immediately degrade upon contact with even trace amounts of oxygen.

What Argon Specifically Protects

Protecting the Specimen

The primary goal is to preserve the integrity of the part being coated.

Argon prevents high-temperature oxidation of the specimen surface.

This ensures the substrate remains metallic and receptive to the diffusion elements, rather than forming a brittle oxide scale.

Preserving Low-Melting-Point Melts

Diffusion processes often utilize low-melting-point metals to facilitate element transfer.

These melts are highly susceptible to oxidation and volatilization.

The inert argon atmosphere stabilizes these melts, ensuring they remain active and effective throughout the diffusion cycle.

Safeguarding Working Ampoules

The protection extends to the processing equipment itself, such as the working ampoules.

Argon prevents these containers from oxidizing and degrading under thermal stress.

This prevents cross-contamination where material from the ampoule might leach into the coating.

Ensuring Reaction Specificity

Isolating the Chemistry

The ultimate engineering goal is precise chemical control.

You want the diffusion elements to react only with the substrate.

Argon acts as a neutral medium, preventing atmospheric interference and ensuring the resulting coating composition is exactly as designed.

Understanding the Trade-offs

The Requirement for High Purity

Standard industrial argon is often insufficient for these processes.

You must use high-purity argon; traces of moisture or oxygen within the gas supply itself can compromise the entire batch at these temperatures.

Using lower-grade gas introduces the very impurities you are trying to avoid.

Vacuum Integrity vs. Argon Filling

Argon cannot "fix" a leaking furnace.

If the initial vacuum does not reach the required 10⁻¹ to 10⁻² Pa, filling the chamber with argon will simply trap residual contaminants inside.

The argon fill is only effective if the initial evacuation was successful.

Making the Right Choice for Your Goal

To ensure a high-quality diffusion coating, align your process parameters with your specific objectives:

- If your primary focus is Surface Purity: Ensure the furnace is evacuated strictly to 10⁻² Pa before introducing argon to eliminate all pre-existing contaminants.

- If your primary focus is Process Consistency: Monitor the argon purity levels to guarantee that the gas itself does not introduce trace oxygen during the 1273 K–1473 K heating cycle.

By strictly controlling the atmosphere with high-purity argon, you convert a chaotic thermal environment into a precise chemical reactor.

Summary Table:

| Feature | Requirement/Parameter | Purpose in Diffusion Coating |

|---|---|---|

| Vacuum Pressure | 10⁻¹ to 10⁻² Pa | Removes atmospheric air and moisture contaminants. |

| Temperature Range | 1273 K to 1473 K | Facilitates element transfer and substrate bonding. |

| Inert Medium | High-Purity Argon | Prevents oxidation of specimens, melts, and ampoules. |

| Gas Function | Thermodynamic Isolation | Ensures reaction specificity between elements and substrate. |

Elevate Your Coating Precision with KINTEK

Maximize the integrity of your thermal processes with industry-leading laboratory equipment. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as other lab high-temperature furnaces. Our systems are fully customizable to meet the unique requirements of your diffusion coating and material research applications.

Ready to optimize your high-temperature environment? Contact us today to discuss how our specialized vacuum furnaces can provide the precise chemical control your lab demands.

Visual Guide

References

- Ismatov Jumaniez Faizullaevich. Mplementation Of The Process Of High Temperature Diffusion Treatment. DOI: 10.37547/ajast/volume05issue11-22

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Magnesium Extraction and Purification Condensing Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What advantages does a laboratory vacuum oven offer over a conventional oven for Pb SA/OSC catalyst drying?

- What are the advantages of vacuum firing? Achieve Ultra-High Vacuum & Magnetic Purity for Sensitive Experiments

- What makes vacuum brazing a preferred method for medical device manufacturing? Discover Unmatched Cleanliness and Strength

- What material treatments can be performed in a vacuum furnace? Achieve Clean, High-Quality Results

- Why are vacuum chamber furnaces essential for industrial heat treatment? Ensure Contaminant-Free Precision

- What safety measures are important for vacuum annealing furnaces? Ensure Reliable Operation and Protect Your Lab

- Why is a vacuum oven necessary for drying ZnO-Co3O4 electrode slurries? Preserve Material Integrity at 60°C

- What types of materials are suitable for vacuum sintering furnaces? Ideal for Reactive Metals and High-Purity Applications