In the high-stakes world of medical manufacturing, vacuum brazing is the preferred joining method for its unique ability to create exceptionally clean, strong, and hermetically sealed joints. This process is critical for ensuring the biocompatibility, reliability, and safety demanded by surgical instruments, implants, and diagnostic equipment, where failure is not an option.

The preference for vacuum brazing in medical applications isn't just about achieving a strong bond; it's about the inherent purity of the process. By eliminating atmospheric contaminants and the need for corrosive fluxes, it produces joints that are not only robust but also fundamentally clean and biocompatible from the start.

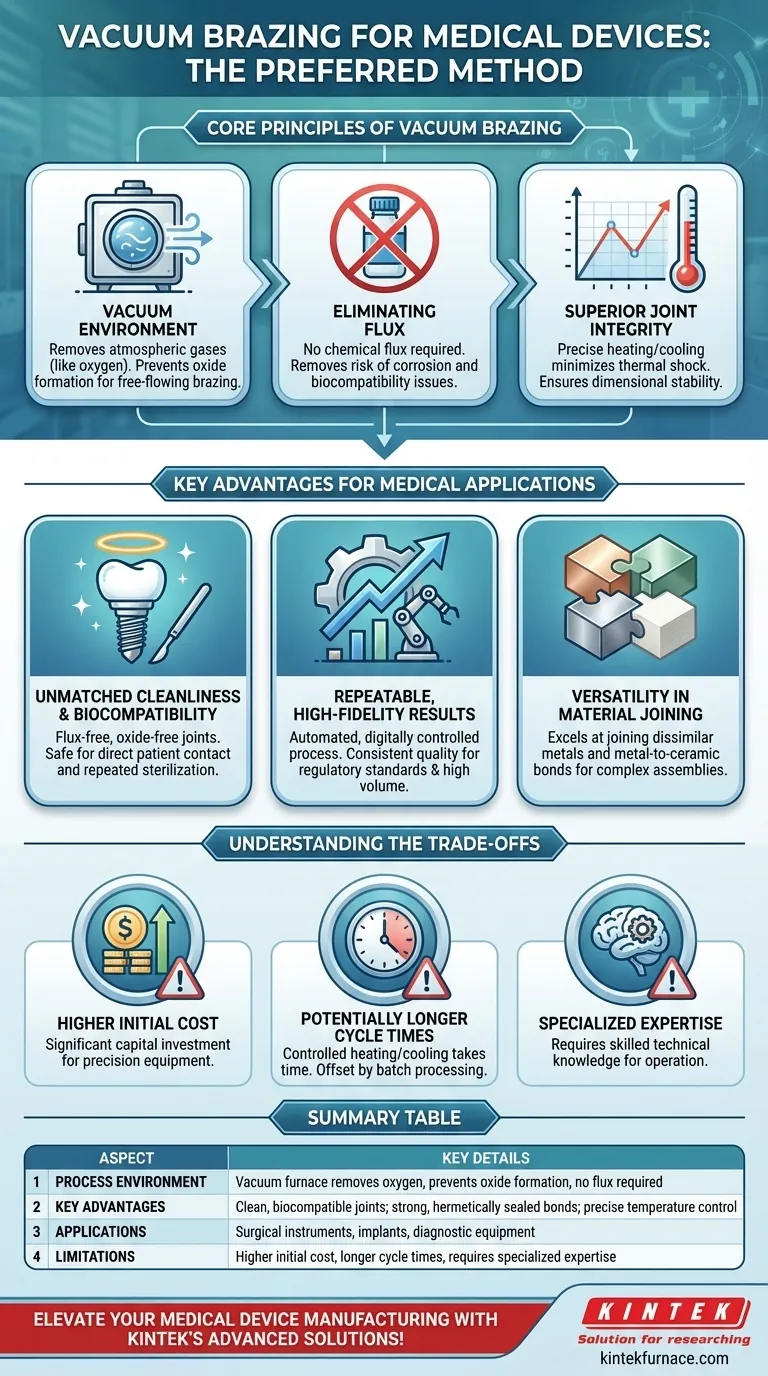

The Core Principles of Vacuum Brazing

To understand why vacuum brazing is so trusted, you must first understand the fundamental problems it solves. The process is defined by its controlled environment.

The Role of the Vacuum Environment

A vacuum furnace removes atmospheric gases—most importantly, oxygen—before heating the components. This prevents the formation of oxides on the metal surfaces.

Without this protective layer of oxides, the molten brazing filler alloy can flow freely and wet the parent materials completely, creating a superior metallurgical bond.

Eliminating the Need for Flux

In traditional brazing, a chemical agent called flux is required to clean away oxides. However, flux is corrosive and poses a significant risk in medical devices.

If flux becomes trapped within a joint, it can lead to corrosion, joint failure, and—most critically—biocompatibility issues. Vacuum brazing completely eliminates this risk because no flux is used. The result is a pure, "shiny, bright" joint.

Achieving Superior Joint Integrity

The process allows for precise control over heating and cooling rates. Slow, uniform heating across the entire assembly minimizes thermal shock and residual stress.

This controlled cycle ensures the finished part is dimensionally stable and free from the distortions that can compromise the function of a precision medical instrument.

Key Advantages for Medical Applications

These core principles deliver specific, tangible benefits that directly address the stringent requirements of the medical industry.

Unmatched Cleanliness and Biocompatibility

The flux-free, oxide-free joints created in a vacuum are inherently clean. This eliminates the need for intensive post-brazing cleaning processes and ensures the final product is safe for direct patient contact.

This is non-negotiable for permanent implants and reusable surgical tools that undergo repeated sterilization.

Ensuring Repeatable, High-Fidelity Results

Vacuum brazing is a highly automated and digitally controlled process. Every parameter—from the vacuum level to the temperature ramp rate and cooling cycle—is programmable and repeatable.

This guarantees consistent quality from the first part to the last, which is essential for process validation and meeting regulatory standards from bodies like the FDA. It also makes the process ideal for high-volume production.

Versatility in Material Joining

Many advanced medical devices are made from dissimilar materials. Vacuum brazing excels at joining different metals and even bonding metals to ceramics.

This capability is crucial for creating complex assemblies, such as diagnostic equipment components or surgical tools that require both strength and insulating properties.

Understanding the Trade-offs

While powerful, vacuum brazing is not a universal solution. An objective assessment requires understanding its limitations.

Higher Initial Equipment Cost

Vacuum furnaces represent a significant capital investment compared to the equipment needed for torch or induction brazing. The cost is a direct reflection of the process's precision and control.

Potentially Longer Cycle Times

The controlled, slow heating and cooling rates required to minimize stress mean that a vacuum furnace cycle can be longer than other joining methods. However, this is often offset by the ability to process large batches of parts at once and combine brazing with heat-treating in a single run.

Requirement for Specialized Expertise

Operating a vacuum furnace and developing a robust brazing profile requires significant technical knowledge. It is not a simple "plug-and-play" process and demands skilled engineers and operators to achieve optimal results.

Making the Right Choice for Your Device

Selecting the right manufacturing process depends entirely on your primary goal. Vacuum brazing is a strategic choice when quality and safety cannot be compromised.

- If your primary focus is patient safety and biocompatibility: Vacuum brazing is the definitive choice, as its flux-free process eliminates the risk of trapped corrosive agents in critical implants and instruments.

- If your primary focus is mechanical strength and reliability: The controlled heating and cooling cycles minimize residual stress, producing dimensionally stable and fatigue-resistant components ideal for long-life devices.

- If your primary focus is production efficiency and consistency: Vacuum brazing offers unparalleled repeatability, allowing you to combine brazing and heat-treating steps into a single, validated, and scalable cycle.

Ultimately, adopting vacuum brazing is an investment in process control that yields a fundamentally safer and more reliable medical product.

Summary Table:

| Aspect | Key Details |

|---|---|

| Process Environment | Vacuum furnace removes oxygen, prevents oxide formation, no flux required |

| Key Advantages | Clean, biocompatible joints; strong, hermetically sealed bonds; precise temperature control |

| Applications | Surgical instruments, implants, diagnostic equipment |

| Limitations | Higher initial cost, longer cycle times, requires specialized expertise |

Elevate your medical device manufacturing with KINTEK's advanced vacuum brazing solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems, including Vacuum & Atmosphere Furnaces, tailored to your unique needs. Our deep customization ensures precise, reliable joints for surgical tools, implants, and diagnostic equipment, enhancing biocompatibility and safety. Contact us today to discuss how our expertise can optimize your production process!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- How does a vacuum heat treatment furnace prevent contamination? Ensure Purity in High-Temperature Processes

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control

- What is a vacuum furnace and what processes can it perform? Unlock Precision Heat Treatment Solutions

- What does the vacuum system of a vacuum furnace consist of? Essential Components for Clean Heat Processing