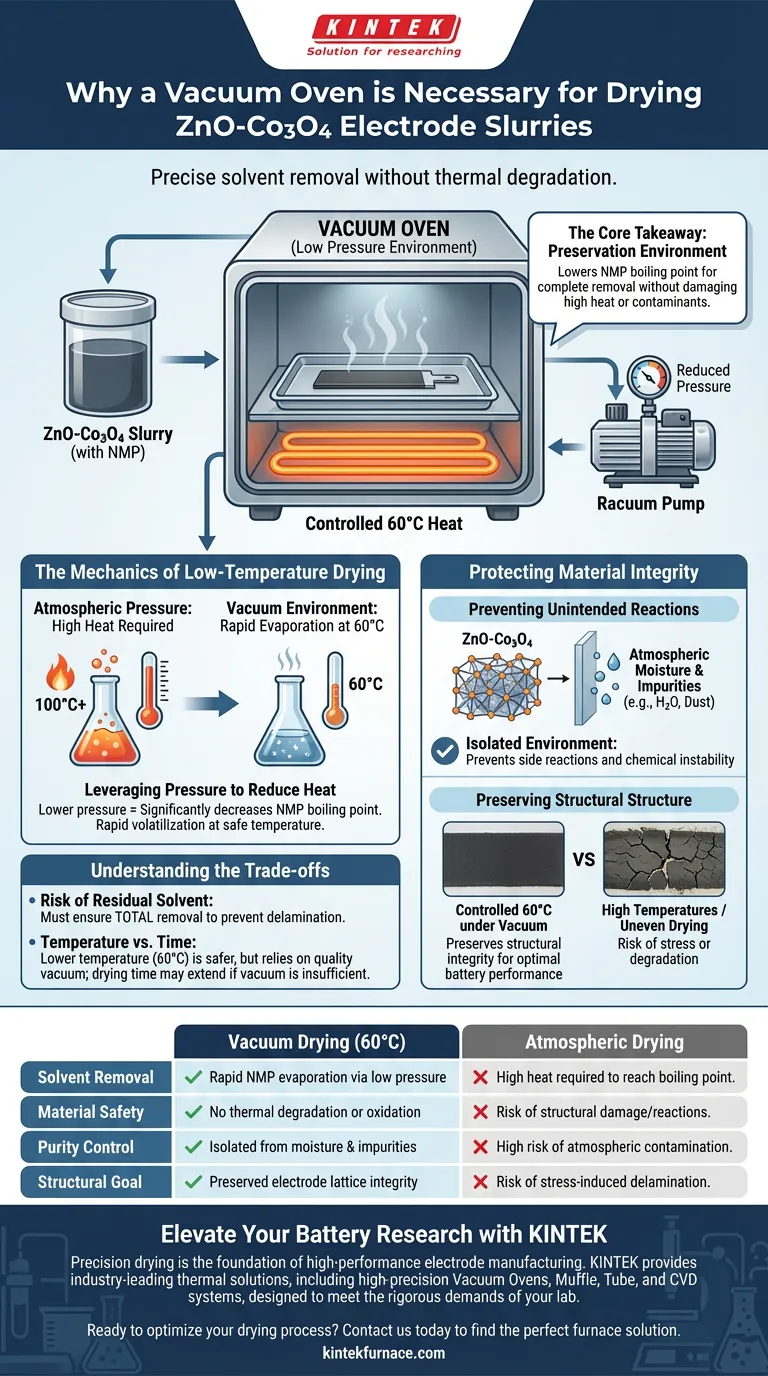

Precise solvent removal without thermal degradation. A vacuum oven is strictly necessary for drying ZnO-Co3O4 electrode slurries to efficiently remove N-Methyl-2-pyrrolidone (NMP) solvents at a safe, low temperature of 60°C. This specific environment accelerates solvent evaporation while simultaneously shielding the active materials from reacting with atmospheric moisture or impurities.

Core Takeaway The vacuum oven is not just a drying tool; it is a preservation environment. It lowers the boiling point of NMP, allowing for complete solvent removal without subjecting the delicate ZnO-Co3O4 structure to damaging high heat or environmental contaminants.

The Mechanics of Low-Temperature Drying

Overcoming the NMP Barrier

N-Methyl-2-pyrrolidone (NMP) is a common solvent in electrode preparation, but it is difficult to remove completely without significant energy.

Under standard atmospheric pressure, removing NMP often requires temperatures that could be detrimental to the slurry components.

Leveraging Pressure to Reduce Heat

The vacuum oven solves this by lowering the pressure within the drying chamber.

By reducing the atmospheric pressure, the boiling point of the NMP solvent decreases significantly.

This allows the solvent to volatilize rapidly at just 60°C, a temperature that is safe for the ZnO-Co3O4 composite.

Protecting Material Integrity

Preventing Unintended Reactions

ZnO-Co3O4 active materials are sensitive to their environment during the curing phase.

The vacuum creates an isolated environment that prevents the slurry from interacting with atmospheric moisture or airborne impurities.

This is critical because moisture ingress can lead to side reactions that compromise the chemical stability of the electrode.

Preserving Structural Structure

High temperatures or uneven drying can cause stress or degradation in the electrode coating.

By drying at a controlled 60°C under vacuum, the process preserves the structural integrity of the electrode.

This ensures the active materials maintain the correct molecular arrangement required for optimal battery performance.

Understanding the Trade-offs

The Risk of Residual Solvent

While the vacuum aids evaporation, the process must be maintained long enough to ensure total removal.

Failing to remove all NMP can lead to electrode delamination or poor adhesion to the current collector later in the process.

Temperature vs. Time

Using a lower temperature like 60°C is safer for the material, but it relies heavily on the quality of the vacuum to be efficient.

If the vacuum pressure is not sufficiently low, the drying time may extend significantly compared to higher-temperature methods used for more robust materials (such as graphite or silicon-based anodes).

Making the Right Choice for Your Goal

To ensure the highest quality ZnO-Co3O4 electrode, apply these principles:

- If your primary focus is Material Purity: strictly maintain the temperature at 60°C to prevent thermal degradation or oxidation of the active components.

- If your primary focus is Structural Stability: Ensure a consistent, deep vacuum is applied to prevent moisture-induced side reactions or impurities from compromising the electrode lattice.

Success lies in using the vacuum to substitute pressure for heat, achieving dryness without destruction.

Summary Table:

| Feature | Vacuum Drying (60°C) | Atmospheric Drying |

|---|---|---|

| Solvent Removal | Rapid NMP evaporation via low pressure | High heat required to reach boiling point |

| Material Safety | No thermal degradation or oxidation | Risk of structural damage/reactions |

| Purity Control | Isolated from moisture & impurities | High risk of atmospheric contamination |

| Structural Goal | Preserved electrode lattice integrity | Risk of stress-induced delamination |

Elevate Your Battery Research with KINTEK

Precision drying is the foundation of high-performance electrode manufacturing. KINTEK provides industry-leading thermal solutions, including high-precision Vacuum Ovens, Muffle, Tube, and CVD systems, designed to meet the rigorous demands of your lab.

Backed by expert R&D and manufacturing, our systems ensure your ZnO-Co3O4 slurries and other sensitive materials are processed with the exact temperature control and vacuum stability required to prevent degradation and maximize performance. All our laboratory high-temp furnaces are fully customizable to your unique research needs.

Ready to optimize your drying process? Contact us today to find the perfect furnace solution.

Visual Guide

References

- Х. А. Абдуллин, Abay Serikkanov. Enhancing the Electrochemical Performance of ZnO-Co3O4 and Zn-Co-O Supercapacitor Electrodes Due to the In Situ Electrochemical Etching Process and the Formation of Co3O4 Nanoparticles. DOI: 10.3390/en17081888

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- Why is a vacuum annealing furnace required for WSe2 Schottky detectors? Optimize Interfaces for Peak Performance

- What are the advantages of horizontal vacuum furnaces in terms of space and integration? Optimize Your Lab's Layout and Efficiency

- What is the purpose of a high vacuum welding furnace in cemented carbide and tool manufacturing? Ensure Strong, Contamination-Free Bonds

- What is the purpose of utilizing a high vacuum system and vacuum sealing? Ensure Purity in Alloy Synthesis

- How do Vacuum Spark Plasma Sintering (SPS) systems compare to traditional furnaces? Achieve Nanometric Grain Control

- How are vacuum furnaces used in metal heat treatment? Enhance Metal Quality with Precision Heat Processing

- What factors are critical for the proper functioning of a vacuum furnace? Maximize Material Purity and Process Control

- How do inert gas technology, airflow, and air pressure work together in vacuum furnaces? Optimize Your Heat Treatment Process