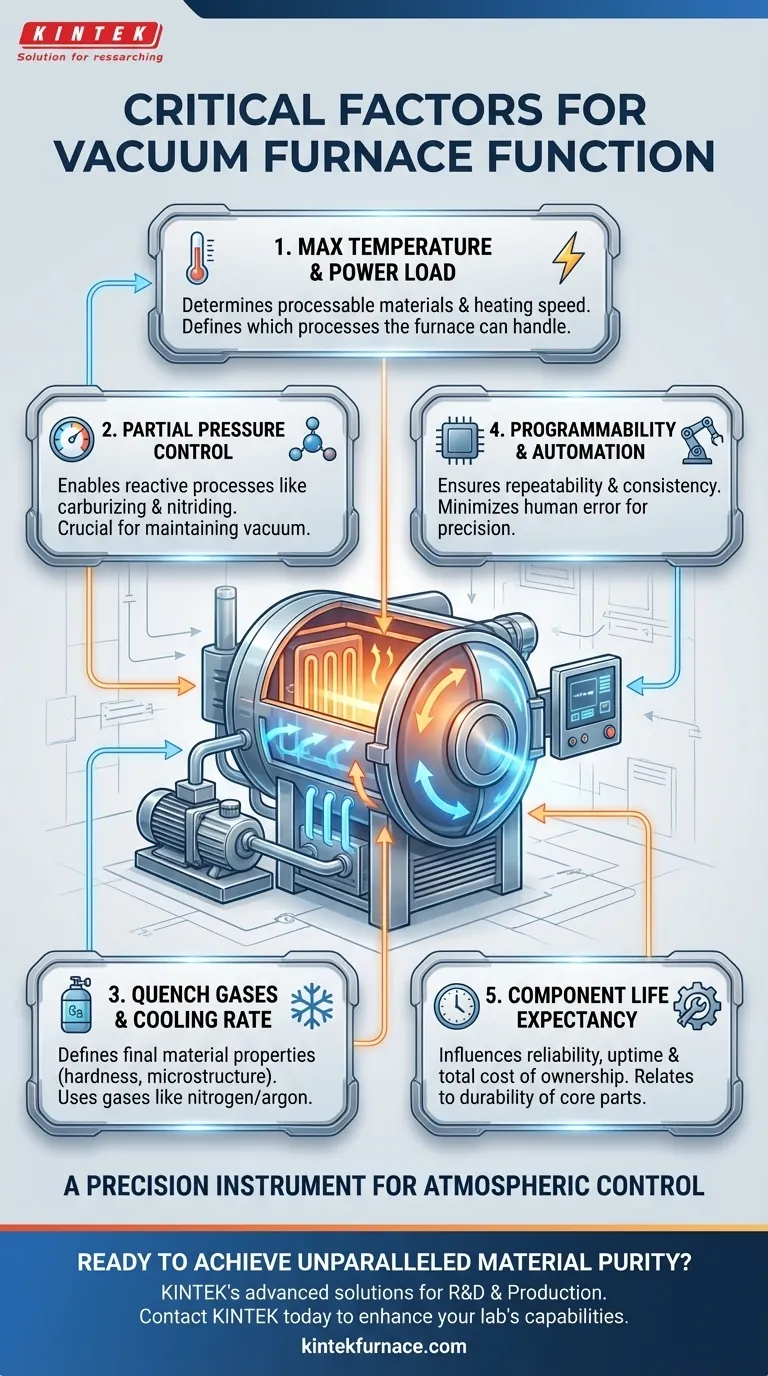

At its core, a vacuum furnace's proper function depends on five critical factors. These are the furnace's maximum operating temperature and power load, its ability to control partial pressure, the type of quench gases used for cooling, and the operational life expectancy of its core components. Together, these elements dictate the furnace's ability to create a highly controlled, low-contamination environment for processing materials like metals.

A vacuum furnace is not merely a device for heating; it is a precision instrument for atmospheric control. Its success hinges on the seamless integration of systems that create the vacuum, generate heat, and manage cooling, ensuring the final material possesses the exact properties required.

Deconstructing the System: The Core Components of Control

To understand the critical operating factors, we must first understand the fundamental components of any vacuum furnace. Each part serves a specific function in creating and maintaining the highly controlled environment necessary for treatment.

The Vacuum Chamber

This is the sealed vessel where the entire process takes place. It must be robust enough to withstand both the extreme internal temperatures and the pressure differential created by the vacuum.

The Heating System

This system, comprised of heating elements, is responsible for raising the material's temperature. The design of these elements and their power source directly impacts the furnace's maximum temperature, heating speed, and temperature uniformity.

The Vacuum System

A series of vacuum pumps works to remove air and other gases from the chamber. This creates the vacuum atmosphere, which prevents oxidation and contamination of the materials being processed.

The Temperature Control System

This is the brain of the operation. Modern systems allow for precise, programmable control over heating rates, holding times, and cooling profiles, ensuring the process is repeatable and accurate.

The Cooling System

After heating, the material must be cooled in a controlled manner to achieve the desired metallurgical properties. This system often uses water-cooled chamber walls and may introduce inert quench gases to accelerate the cooling rate.

Translating Components into Critical Operating Factors

The performance of the components above directly translates into the key factors that determine a furnace's suitability for a specific task.

Maximum Temperature and Power Load

The furnace's heating elements and power supply define its maximum operating temperature and how quickly it can reach it. This is the most fundamental specification, as it determines which materials and processes the furnace can handle.

Partial Pressure Control

A high-quality vacuum system doesn't just create a vacuum; it maintains it. The ability to introduce specific gases at a controlled partial pressure is crucial for processes like vacuum carburizing or nitriding, where a reactive atmosphere is required.

Quench Gases and Cooling Rate

The cooling system dictates the final microstructure and hardness of the material. The choice of quench gas (like nitrogen or argon) and the pressure at which it's introduced are critical variables that control the cooling rate, effectively "locking in" the desired properties.

Programmability and Automation

A sophisticated control system enhances precision and reliability. The ability to program and automate the entire cycle—from heating to pressure changes to quenching—minimizes human error and ensures high consistency from batch to batch.

Understanding the Trade-offs: Design and Reliability

Not all vacuum furnaces are created equal. Their design and construction have significant implications for performance, cost, and long-term reliability.

Hot Wall vs. Cold Wall Designs

Hot wall furnaces have heating elements outside the vacuum chamber, which limits their maximum temperature. Cold wall furnaces, where the heating elements are inside the water-cooled chamber, can achieve much higher temperatures, faster heating and cooling cycles, and better temperature uniformity.

Component Durability and Life Expectancy

The quality of the heating elements, the vacuum chamber, and the pumps directly impacts the furnace's reliability and maintenance costs. The life expectancy of components is a critical factor in the total cost of ownership and operational uptime.

Safety and Efficiency Features

Modern furnaces incorporate essential safety features, such as automatic power-off functions when the door is opened. Advanced designs also have lower heat storage, allowing for faster temperature changes and providing significant energy-saving effects compared to older, refractory-lined furnaces.

Making the Right Choice for Your Goal

The "best" furnace is the one whose characteristics align perfectly with your primary objective.

- If your primary focus is material purity and consistency: Prioritize a furnace with a high-performance vacuum system and precise, programmable controls for temperature and partial pressure.

- If your primary focus is high-throughput production: Look for a furnace with rapid heating and cooling capabilities, robust automation, and durable components designed for continuous operation.

- If your primary focus is versatility for research and development: Select a furnace with a wide operating temperature range, flexible partial pressure options, and a highly programmable control system to accommodate diverse processes.

Ultimately, a vacuum furnace's proper function is a result of a balanced system where each component works in concert to deliver a precisely controlled thermal process.

Summary Table:

| Critical Factor | Key Impact on Performance |

|---|---|

| Maximum Temperature & Power Load | Determines processable materials and heating speed. |

| Partial Pressure Control | Enables reactive processes like carburizing and nitriding. |

| Quench Gases & Cooling Rate | Defines final material properties like hardness and microstructure. |

| Programmability & Automation | Ensures repeatability, consistency, and minimizes human error. |

| Component Life Expectancy | Directly influences reliability, uptime, and total cost of ownership. |

Ready to achieve unparalleled material purity and process control?

KINTEK's advanced vacuum furnace solutions are engineered for precision. Leveraging our exceptional in-house R&D and manufacturing, we provide high-temperature furnaces with superior vacuum integrity, precise partial pressure control, and rapid quench capabilities. Our product line, including Vacuum & Atmosphere Furnaces, is complemented by deep customization to meet your unique requirements for R&D or high-throughput production.

Contact KINTEL today to discuss how our reliable, high-performance vacuum furnaces can enhance your lab's capabilities and efficiency.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing