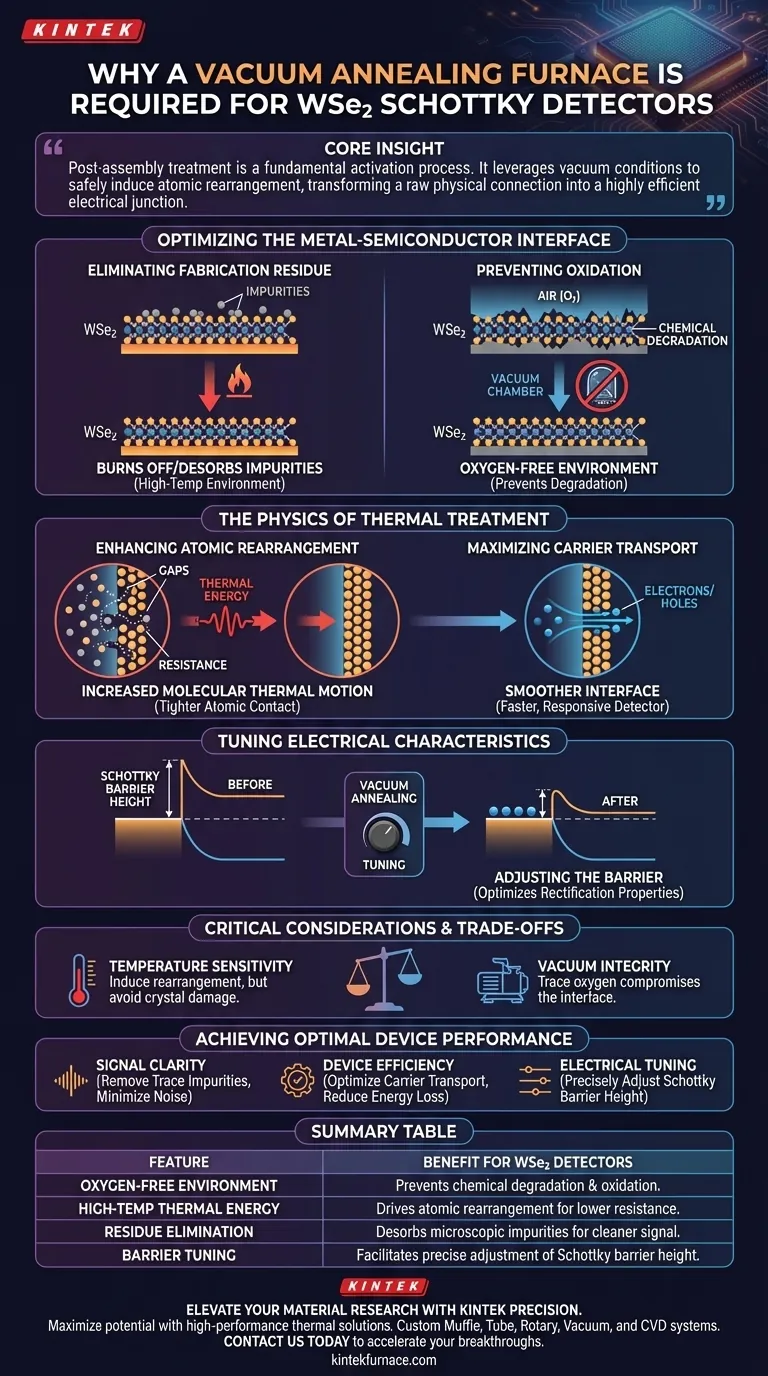

A vacuum annealing furnace is essential for WSe2 Schottky detectors because it creates a pristine, high-temperature environment necessary to optimize the critical interface between the semiconductor and the electrode. By removing oxygen and increasing thermal energy, this process eliminates fabrication residues and structurally refines the contact area to ensure the device functions correctly.

Core Insight: The post-assembly treatment is not just a cleaning step; it is a fundamental activation process. It leverages vacuum conditions to safely induce atomic rearrangement, transforming a raw physical connection into a highly efficient electrical junction.

Optimizing the Metal-Semiconductor Interface

The primary challenge in assembling WSe2 detectors is the quality of the contact point between the 2D material and the metal electrode. The vacuum annealing furnace addresses this through two specific mechanisms.

Eliminating Fabrication Residue

During the transfer process of WSe2, trace impurities often adhere to the material surfaces.

These microscopic contaminants can act as barriers to electrical current. The high-temperature environment of the furnace effectively burns off or desorbs these remaining impurities.

Preventing Oxidation

Standard heating methods in air would destroy the sensitive WSe2 material.

The "vacuum" component of the furnace is critical because it provides an oxygen-free environment. This allows the device to reach the necessary temperatures for treatment without chemically degrading or oxidizing the semiconductor components.

The Physics of Thermal Treatment

Beyond cleaning, the heat applied in the furnace drives physical changes at the atomic level that are required for high performance.

Enhancing Atomic Rearrangement

The furnace significantly increases molecular thermal motion at the interface between the WSe2 and the electrode.

This increased kinetic energy allows atoms to shift and settle into more energetically favorable positions. The result is a tighter, more uniform atomic contact that reduces physical gaps and resistance.

Maximizing Carrier Transport

By smoothing out the interface and removing impurities, the treatment optimizes carrier transport efficiency.

Electrons (or holes) can move across the junction with less scattering and resistance. This directly translates to a faster, more responsive detector.

Tuning Electrical Characteristics

The ultimate goal of the annealing process is to finalize the electronic behavior of the Schottky diode.

Adjusting the Schottky Barrier Height

The Schottky barrier height determines how easily current can flow through the junction and defines the detector's rectification properties.

Annealing facilitates the final adjustment of this energy barrier. By refining the metal-semiconductor contact, the furnace ensures the barrier height is optimized for the specific detection requirements of the device.

Critical Considerations and Trade-offs

While vacuum annealing is required, the process relies on a delicate balance of parameters.

Temperature Sensitivity

The temperature must be high enough to induce atomic rearrangement but not so high that it damages the crystal structure of the WSe2.

Vacuum Integrity

The quality of the vacuum is non-negotiable. Even trace amounts of oxygen during the high-temperature phase can compromise the interface quality, negating the benefits of the annealing process.

Achieving Optimal Device Performance

The vacuum annealing furnace is the bridge between a fabricated assembly and a working high-performance detector.

- If your primary focus is signal clarity: Prioritize the removal of trace impurities to minimize noise and resistance at the contact interface.

- If your primary focus is device efficiency: Focus on the atomic rearrangement aspect to optimize carrier transport and reduce energy loss.

- If your primary focus is electrical tuning: Use the thermal treatment to precisely adjust the Schottky barrier height for your specific voltage requirements.

This process ensures that the physical connection at the interface becomes an effective electrical junction.

Summary Table:

| Feature | Benefit for WSe2 Detectors |

|---|---|

| Oxygen-Free Environment | Prevents chemical degradation and oxidation of sensitive 2D materials. |

| High-Temp Thermal Energy | Drives atomic rearrangement to minimize physical gaps and contact resistance. |

| Residue Elimination | Desorbs microscopic fabrication impurities for cleaner signal transport. |

| Barrier Tuning | Facilitates precise adjustment of Schottky barrier height for optimal rectification. |

Elevate Your Material Research with KINTEK Precision

Maximize the potential of your WSe2 Schottky detectors with KINTEK’s high-performance thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to your specific laboratory needs.

Whether you are refining 2D material interfaces or developing next-generation semiconductors, our vacuum furnaces provide the thermal integrity and oxygen-free precision required for superior electrical junctions. Contact us today to discuss your unique requirements and discover how our advanced heating technology can accelerate your breakthroughs.

Visual Guide

References

- Jian Li, Shaoqing Xiao. Ultrafast Self‐Driven WSe <sub>2</sub> Photodetectors with Bottom Schottky Contacts. DOI: 10.1002/advs.202510373

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is the objective of using a high-temperature carbonization furnace for hard carbon synthesis? Optimize Performance

- What design solutions address challenges in vacuum sintering? Optimize Sintering for High-Performance Materials

- What is the function of a molten salt electrochemical cell or furnace? Efficient Silicon Material Production Secrets

- Why is high vacuum control essential for CNT/Cu composites? Unlock Peak Conductivity and Purity

- How is furnace brazing applied in the energy and power generation sectors? Enhance Component Reliability in Extreme Conditions

- Why is temperature stability important in vacuum furnace operations? Ensure Precise Heat Treatment for Superior Materials

- What types of pumps are used for vacuum brazing? Master the Staged System for High-Purity Brazing

- Why is a high vacuum system critical for sealing the quartz tube used in Fe3GeTe2 single crystal preparation?