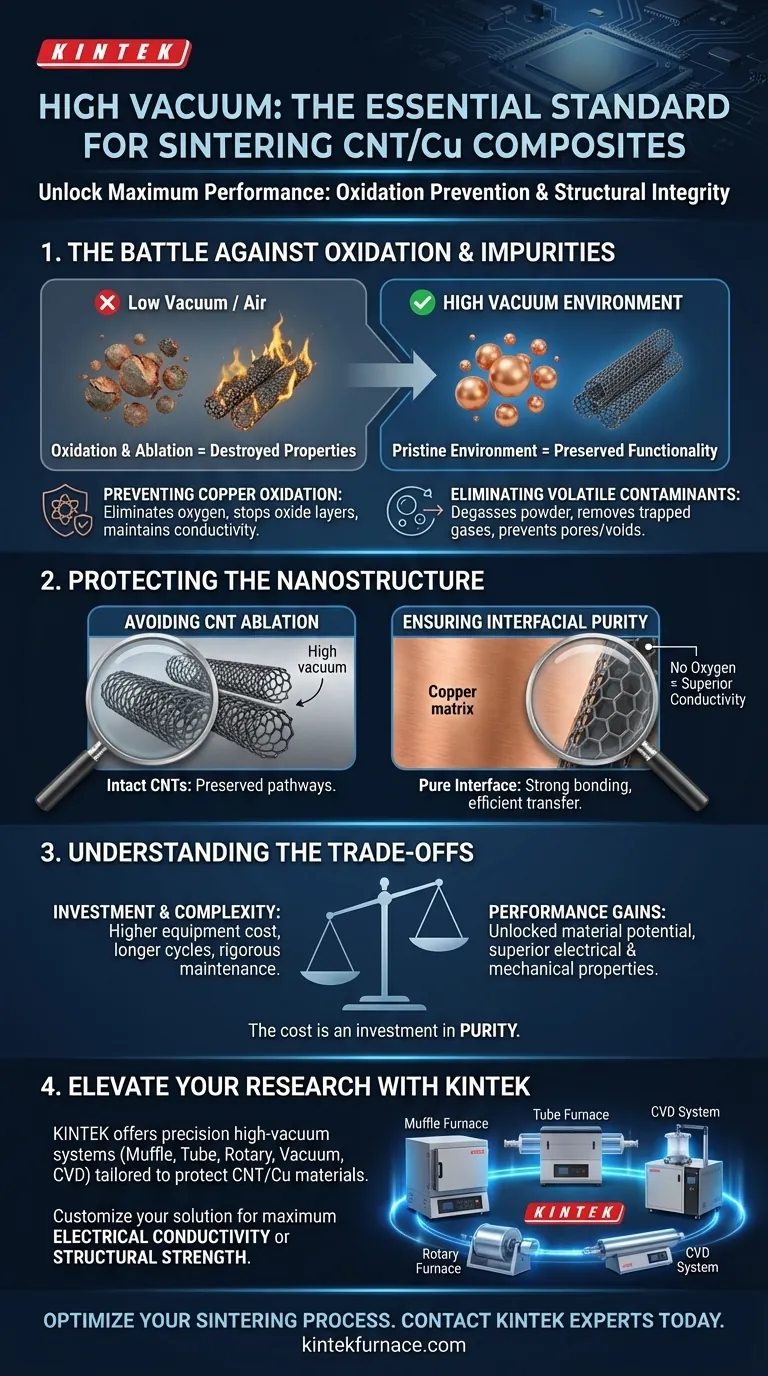

High vacuum control is the non-negotiable standard for sintering high-performance carbon nanotube (CNT) and copper composites. Its primary role is to create a pristine environment that physically removes adsorbed volatile impurities and chemically prevents the oxidation of the copper matrix. Without this capability, the high temperatures required for sintering would destroy the functional properties of both materials before the composite is formed.

Creating high-performance composites requires more than just mixing materials; it requires preserving their fundamental properties during processing. A high vacuum environment eliminates oxygen to protect the copper matrix from oxidation and carbon nanotubes from ablation, ensuring a pure interface that facilitates superior conductivity.

The Battle Against Oxidation and Impurities

Preventing Copper Oxidation

Copper is highly susceptible to oxidation at elevated temperatures. Even trace amounts of oxygen can react with the copper matrix to form oxide layers.

These oxide layers act as electrical and thermal insulators. A high vacuum environment removes oxygen from the chamber, ensuring the copper remains metallic and conductive throughout the heating process.

Eliminating Volatile Contaminants

Powder materials naturally adsorb gases and moisture on their surfaces during storage and handling. If these are not removed, they can become trapped inside the composite during densification.

High vacuum capability effectively degasses the powder, stripping away these volatile impurities. This prevents the formation of pores or voids that would weaken the material's structural integrity.

Protecting the Nanostructure

Avoiding Carbon Nanotube Ablation

Carbon nanotubes possess incredible strength and conductivity, but they are fragile in the presence of oxygen at high heat. In an air or low-vacuum environment, CNTs can suffer from ablation, effectively burning away or degrading structurally.

A high vacuum ensures the nanotubes remain intact. This preservation is vital for maintaining the continuous conductive pathways required for high-performance applications.

Ensuring Interfacial Purity

The performance of a composite is defined by the quality of the interface—the boundary where the copper meets the nanotube.

An oxygen-free environment guarantees a pure interface between the copper and the CNTs. This purity is what facilitates strong interfacial bonding, allowing for efficient electron and phonon transfer between the matrix and the reinforcement.

Understanding the Trade-offs

Equipment Complexity and Cost

Implementing high vacuum systems significantly increases the capital cost of sintering equipment. It requires sophisticated pumps, seals, and chamber designs capable of maintaining extremely low pressures.

Processing Cycle Time

Achieving a high vacuum state takes time. The evacuation process adds to the overall cycle time compared to atmospheric or low-vacuum sintering, potentially impacting production throughput.

Maintenance Requirements

Vacuum systems differ from standard furnaces in their sensitivity. They require rigorous maintenance to prevent leaks, as even a microscopic breach can reintroduce oxygen and ruin an entire batch of high-value composite material.

Making the Right Choice for Your Goal

When selecting sintering equipment for CNT/Cu composites, your choice depends on the specific performance metrics you must hit.

- If your primary focus is Maximum Electrical Conductivity: Prioritize equipment with ultra-high vacuum capabilities to completely eliminate oxide barriers that impede electron flow.

- If your primary focus is Mechanical Strength: Ensure the system offers precise vacuum control to prevent gas entrapment, which leads to porosity and structural failure.

Ultimately, the cost of high vacuum technology is an investment in the purity required to unlock the full potential of carbon nanotubes within a copper matrix.

Summary Table:

| Key Requirement | Impact of High Vacuum Control | Benefit to Composite Performance |

|---|---|---|

| Oxidation Control | Eliminates oxygen to prevent copper oxide layers | Maintains maximum electrical and thermal conductivity |

| Impurity Removal | Degasses volatile contaminants and moisture | Prevents pores/voids for superior structural integrity |

| CNT Protection | Prevents ablation and structural degradation of nanotubes | Preserves high-strength and conductive pathways |

| Interfacial Purity | Ensures a clean boundary between CNT and Copper | Facilitates strong bonding and efficient electron transfer |

Elevate Your Material Research with KINTEK

Unlock the full potential of your high-performance composites with sintering technology designed for precision. Backed by expert R&D and manufacturing, KINTEK offers high-vacuum Muffle, Tube, Rotary, Vacuum, and CVD systems tailored to protect your materials from oxidation and ablation.

Whether you need to maximize electrical conductivity or structural strength, our customizable lab high-temperature furnaces provide the pristine environment your CNT/Copper projects demand.

Ready to optimize your sintering process? Contact our technical experts today to find the perfect solution for your unique research needs.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are the primary functions of a vacuum furnace? Achieve Superior Material Processing in a Controlled Environment

- What is vacuum sintering and where is it commonly used? Discover High-Purity Material Processing

- What are the stages of a vacuum furnace pumping system and how do they function? Learn the Sequential Process for High-Vacuum Efficiency

- Why are vacuum and modified atmosphere furnaces essential for 3D printing? Unlock Dense, Strong Parts with Controlled Sintering

- What role does a high-vacuum or low-oxygen furnace play in NiCoCrAlY pre-oxidation? Master Selective Oxidation Control

- Why is vacuum sublimation preferred over recrystallization for MTO? Achieve High-Purity Methyltrioxorhenium

- What are the types of vacuum furnaces based on heating form? Internal vs. External Heating Explained

- What vacuum level is required for AlCrSiWN coating deposition? Achieving Peak Purity and Adhesion