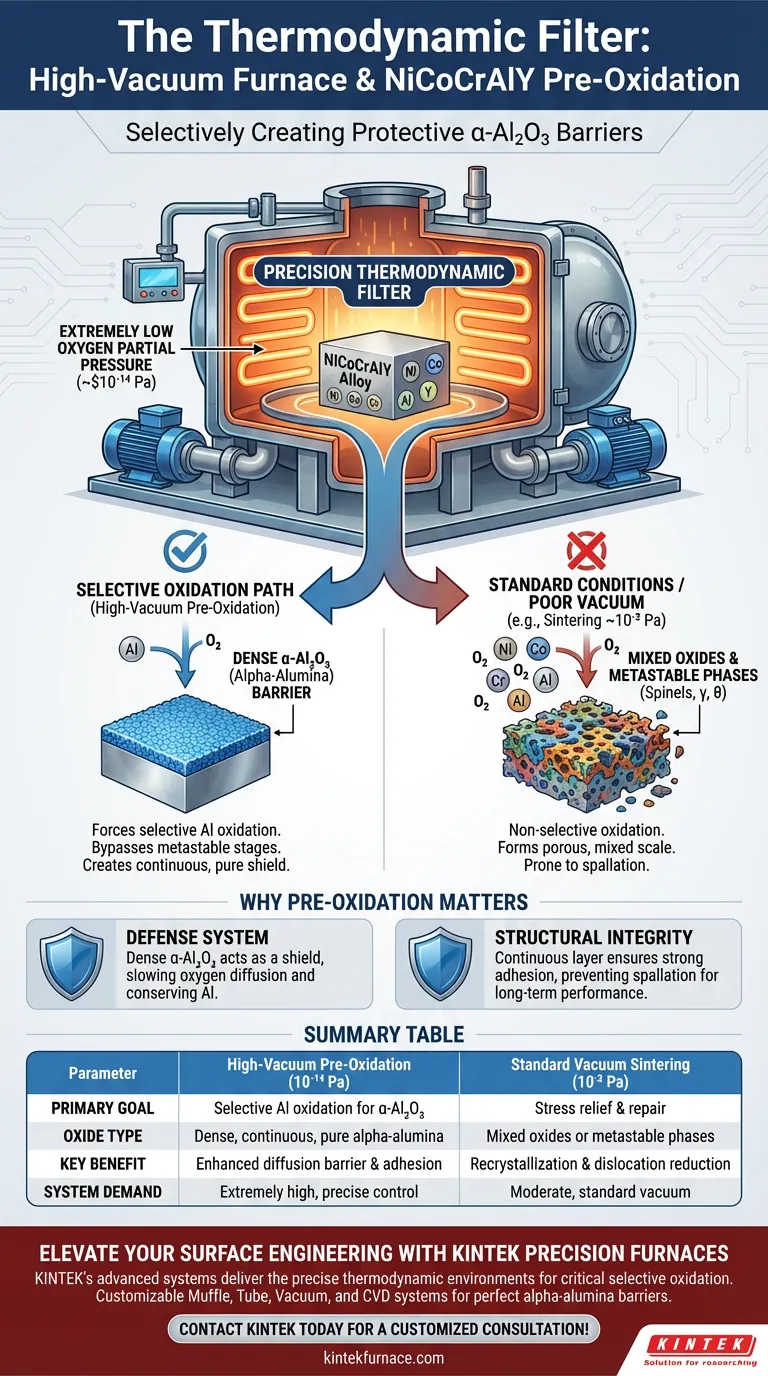

The definitive role of a high-vacuum or low-oxygen partial pressure furnace in this context is to act as a precision thermodynamic filter. It creates an environment that forces the selective oxidation of aluminum while preventing the reaction of other alloy elements. By maintaining an extremely low oxygen partial pressure (specifically around $10^{-14}$ Pa), the furnace facilitates the growth of a specific, protective oxide layer essential for the material's longevity.

The furnace does not simply heat the material; it manipulates the chemical potential of the atmosphere. This specific control allows the system to bypass inferior, metastable oxide stages and directly generate a continuous, dense $\alpha$-Al$_2$O$_3$ (alpha-alumina) barrier on the NiCoCrAlY surface.

The Mechanism of Selective Oxidation

Precise Atmospheric Regulation

The core function of the furnace is to maintain a thermal environment with a specific oxygen partial pressure, ideally near $10^{-14}$ Pa.

At this precise threshold, the atmosphere is "rich" enough to oxidize aluminum but "lean" enough to prevent the oxidation of nickel, cobalt, or chromium.

This selective oxidation is the defining characteristic of the process. Without this control, the alloy would form a mixed, non-protective oxide scale.

Promoting the Alpha-Phase Barrier

The ultimate goal of this heat treatment is the formation of $\alpha$-Al$_2$O$_3$.

Under standard atmospheric conditions, aluminum oxidation often progresses through "metastable" stages (such as gamma or theta phases) before becoming stable alpha-alumina.

The low-oxygen environment allows the system to bypass these metastable stages. This results in a pre-generated barrier layer that is denser and more continuous than one formed under variable conditions.

Why "Pre-Oxidation" Matters

Establishing a Defense System

The dense $\alpha$-Al$_2$O$_3$ layer acts as a shield.

By creating this layer under controlled conditions before the component enters service, you effectively seal the surface.

This barrier slows down the diffusion of oxygen into the alloy and prevents the rapid consumption of aluminum during high-temperature operations.

Structural Integrity

A continuous oxide layer is critical for adhesion.

If the layer is porous or contains mixed oxides (like spinels), it is prone to spallation (flaking off).

The high-vacuum treatment ensures the oxide is chemically pure and mechanically robust, providing a stable foundation for long-term performance.

Understanding the Trade-offs

The Precision Requirement

Achieving an oxygen partial pressure of $10^{-14}$ Pa is technically demanding.

It requires high-performance vacuum systems and precise leak control. Deviating from this pressure—even slightly—can result in the formation of unwanted oxides.

Distinguishing Processes

It is vital to distinguish between pre-oxidation and stress relief/sintering.

While vacuum sintering (often performed at higher pressures like $10^{-2}$ Pa) can repair plastic deformation and relieve stress in coatings like CoNiCrAlY, it does not achieve the same selective chemistry as pre-oxidation.

Using a furnace setup designed only for stress relief may not provide the atmospheric purity required to generate the specific $\alpha$-Al$_2$O$_3$ barrier.

Making the Right Choice for Your Goal

To optimize your heat treatment strategy, align your furnace parameters with your specific metallurgical objective:

- If your primary focus is creating a diffusion barrier: Prioritize a system capable of sustaining extremely low partial pressures ($10^{-14}$ Pa) to force the selective formation of $\alpha$-Al$_2$O$_3$.

- If your primary focus is microstructural repair: A standard vacuum sintering setup ($10^{-2}$ Pa) is sufficient to induce recrystallization and reduce dislocation density, but it will not optimize the oxide scale composition.

Mastering the oxygen partial pressure is the single most critical factor in transforming a standard alloy surface into a high-performance thermal barrier.

Summary Table:

| Parameter | High-Vacuum Pre-Oxidation ($10^{-14}$ Pa) | Standard Vacuum Sintering ($10^{-2}$ Pa) |

|---|---|---|

| Primary Goal | Selective oxidation of Al to form $\alpha$-Al$_2$O$_3$ | Stress relief and microstructural repair |

| Oxide Type | Dense, continuous, pure alpha-alumina | Mixed oxides or metastable phases |

| Key Benefit | Enhanced diffusion barrier & adhesion | Recrystallization & dislocation reduction |

| System Demand | Extremely high (precise atmospheric control) | Moderate (standard vacuum systems) |

Elevate Your Surface Engineering with KINTEK Precision Furnaces

Don't let inferior oxide scales compromise your material performance. KINTEK’s advanced vacuum and CVD systems are engineered to deliver the precise thermodynamic environments required for critical processes like the selective oxidation of NiCoCrAlY.

Backed by expert R&D and manufacturing, we offer customizable Muffle, Tube, Rotary, Vacuum, and CVD systems tailored to your unique lab or production needs. Whether you need to maintain $10^{-14}$ Pa for a perfect alpha-alumina barrier or require robust sintering solutions, our high-temperature technology ensures structural integrity and long-term durability for your alloys.

Ready to optimize your thermal treatment? Contact KINTEK today for a customized consultation!

Visual Guide

References

- Masahiro Negami, Yoko Yamabe‐Mitarai. The Oxidation Behaviors of NiCoCrAlY Coatings After Pre-Oxidation Treatment During High-Temperature Oxidation at 800 ℃ and 900 ℃. DOI: 10.1007/s11085-024-10221-6

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What are some applications of vacuum brazing? Achieve Strong, Clean Joints in Aerospace and More

- Why must the diffusion bonding of ODS steel and nickel alloys be done in a vacuum furnace? Achieve Pore-Free Integrity

- What are the advantages of graphite furnace? Achieve Unmatched High-Temperature Performance

- What processing conditions does a vacuum furnace provide for TiCp/Fe microspheres? Sintering at 900 °C

- How is furnace brazing applied in research and development? A Precision Tool for Material Science & Prototyping

- What are the different types of vacuum furnaces? Find the Perfect Fit for Your Process

- Why is Titanium sponge used as a chemical getter in high-temperature vacuum distillation? Ensure Ultra-High Metal Purity

- What factors must be controlled during furnace brazing to ensure a reliable joint? Master the 5 Key Variables for Strong Bonds