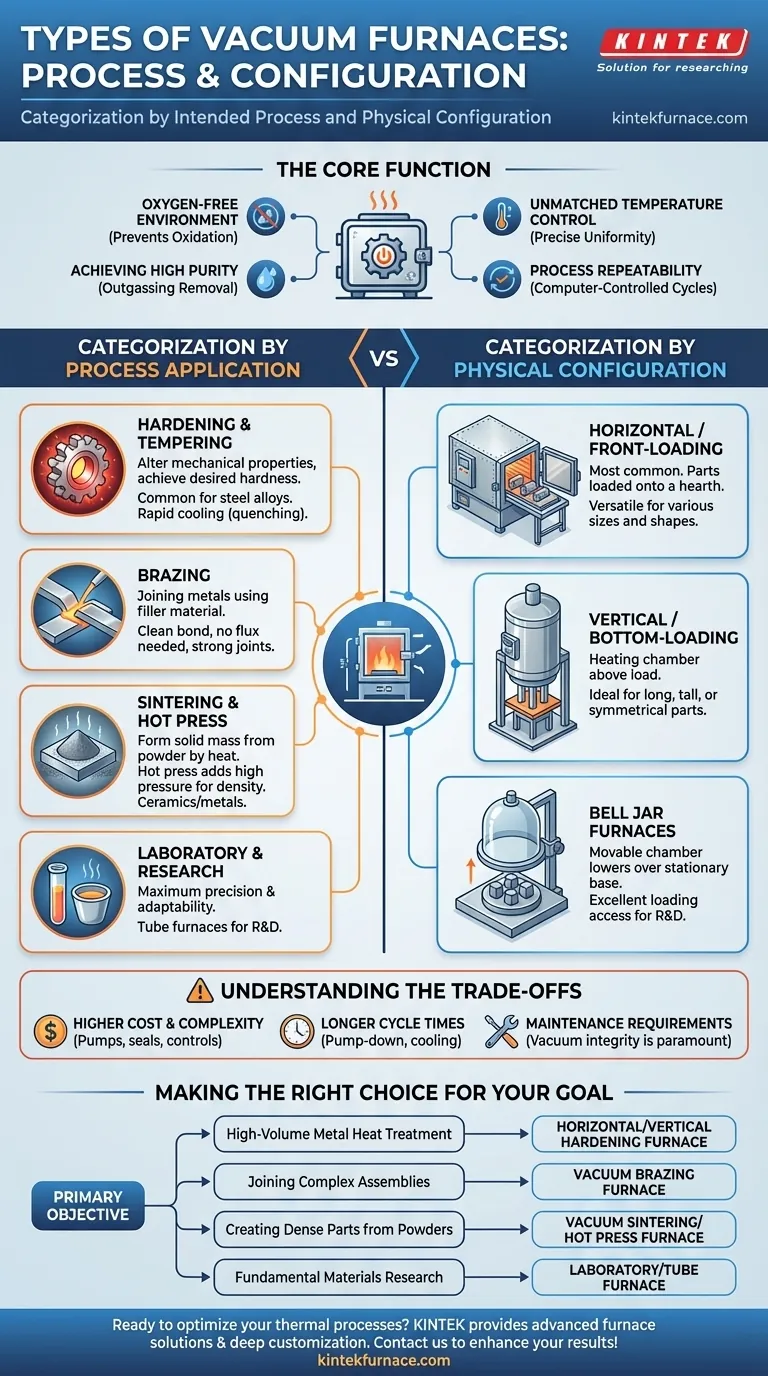

At a fundamental level, vacuum furnaces are categorized in two primary ways: by their intended process and by their physical configuration. Process-based types include hardening, brazing, and sintering furnaces, each designed for a specific material transformation. Configuration-based types, such as horizontal, vertical, or bell jar furnaces, are defined by how materials are loaded and positioned within the heating chamber.

The specific type of vacuum furnace you need is dictated entirely by your end goal. Understanding the difference between a furnace designed for a process (like brazing) and one defined by its physical layout (like bottom-loading) is the key to selecting the right tool for the job.

The Core Function of a Vacuum Furnace

Before categorizing the types, it's critical to understand why a vacuum environment is used. Its primary purpose is to control the atmosphere, which provides several distinct advantages over traditional air-fired furnaces.

An Oxygen-Free Environment

The most important benefit is the removal of oxygen and other reactive gases. This prevents oxidation, scaling, and discoloration on the surface of the material being processed.

Achieving High Purity

The vacuum actively pulls away volatile contaminants and by-products released from the material during heating. This "outgassing" results in a final product with higher purity and superior material properties.

Unmatched Temperature Control

Modern vacuum furnaces offer exceptionally precise and uniform temperature control, often within a few degrees, across a wide range from 800°C to over 3,000°C.

Process Repeatability

With computer-controlled cycles for vacuum levels, heating rates, soak times, and cooling, vacuum furnaces deliver highly repeatable results, which is essential for certified manufacturing and critical applications.

Categorization by Process Application

The most common way to classify a vacuum furnace is by the specific job it is engineered to perform. Each type is optimized for a particular thermal process.

Vacuum Hardening & Tempering Furnaces

These furnaces are the workhorses of the heat-treating industry. They are used to alter the mechanical properties of metals, such as steel alloys, by heating them to a specific temperature and then rapidly cooling (quenching) them to achieve a desired hardness, toughness, and durability.

Vacuum Brazing Furnaces

Brazing is a process for joining two or more metal items by melting and flowing a filler metal into the joint. A vacuum brazing furnace provides a perfectly clean environment, ensuring the filler metal bonds cleanly with the parent materials without the use of flux, creating an exceptionally strong and pure joint.

Vacuum Sintering & Hot Press Furnaces

Sintering is the process of compacting and forming a solid mass of material by heat without melting it to the point of liquefaction. It is commonly used to create parts from metal or ceramic powders. A vacuum hot press furnace adds high pressure to the process, creating even denser, higher-strength components.

Laboratory & Research Furnaces

These furnaces are built for maximum precision, adaptability, and control. They are often smaller and may include specialized configurations like tube furnaces (split, rotating, or gradient) to allow for unique research on material properties in an oxygen-free environment.

Categorization by Physical Configuration

The second method of classification relates to the furnace's physical design and how parts are loaded into it. This choice is driven by part size, shape, and production workflow.

Horizontal / Front-Loading Furnaces

This is the most common configuration. The furnace features a door on the front, and parts are loaded horizontally onto a flat hearth or in baskets. This design is versatile, easy to automate, and suitable for a wide range of part sizes and shapes.

Vertical / Bottom-Loading Furnaces

In a vertical furnace, the heating chamber is positioned above the load, which is raised into the furnace from below. This design is ideal for long, tall, or symmetrical parts (like shafts or gears) that could distort or warp if laid horizontally during heating.

Bell Jar Furnaces

This is a type of vertical furnace where the chamber itself is a movable "bell" that is lowered over a stationary base where the parts are placed. They offer excellent access for loading and are often used in research or specialized production environments.

Understanding the Trade-offs

While powerful, vacuum furnaces introduce complexities that are important to consider.

Higher Initial Cost & Complexity

The addition of vacuum pumps, chambers, seals, and sophisticated control systems makes vacuum furnaces significantly more expensive and complex to operate than their atmospheric counterparts.

Longer Cycle Times

Achieving a deep vacuum requires time for the pumps to evacuate the chamber (pump-down). The subsequent cooling phase must also be carefully controlled, potentially leading to longer overall cycle times compared to simply opening a door to the air.

Maintenance Requirements

The integrity of the vacuum is paramount. This requires diligent and regular maintenance of vacuum pumps, O-rings, seals, and chamber surfaces to prevent leaks that could compromise the process.

Making the Right Choice for Your Goal

Selecting a furnace begins with defining your primary objective.

- If your primary focus is high-volume metal heat treatment: A horizontal or vertical hardening furnace is your most likely choice, depending on part geometry.

- If your primary focus is joining complex, high-value assemblies: A dedicated vacuum brazing furnace with precise zone control is essential for creating clean, strong joints.

- If your primary focus is creating dense parts from powders: A vacuum sintering furnace is the standard, and a hot press furnace is necessary if pressure is required for final density.

- If your primary focus is fundamental materials research: A highly adaptable laboratory furnace, potentially a specialized tube furnace, will provide the precision and control needed for R&D.

Ultimately, the type of furnace is simply a reflection of the material problem you are trying to solve.

Summary Table:

| Category | Types | Key Applications |

|---|---|---|

| Process-Based | Hardening, Brazing, Sintering | Metal hardening, joining assemblies, powder compaction |

| Configuration-Based | Horizontal, Vertical, Bell Jar | Versatile loading, long parts, research environments |

Ready to optimize your thermal processes with the right vacuum furnace? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how we can enhance your efficiency and results!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

People Also Ask

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance