Vacuum brazing is a critical joining process used extensively in high-stakes industries like aerospace, medical, automotive, and defense. It is the preferred method for creating exceptionally strong, clean, and distortion-free joints, particularly in advanced materials that are difficult or impossible to join using conventional welding techniques.

The true value of vacuum brazing isn't just its application in specific components, but its ability to solve fundamental engineering challenges. It enables the creation of complex, high-integrity assemblies from dissimilar or sensitive materials without compromising their structural or metallurgical properties.

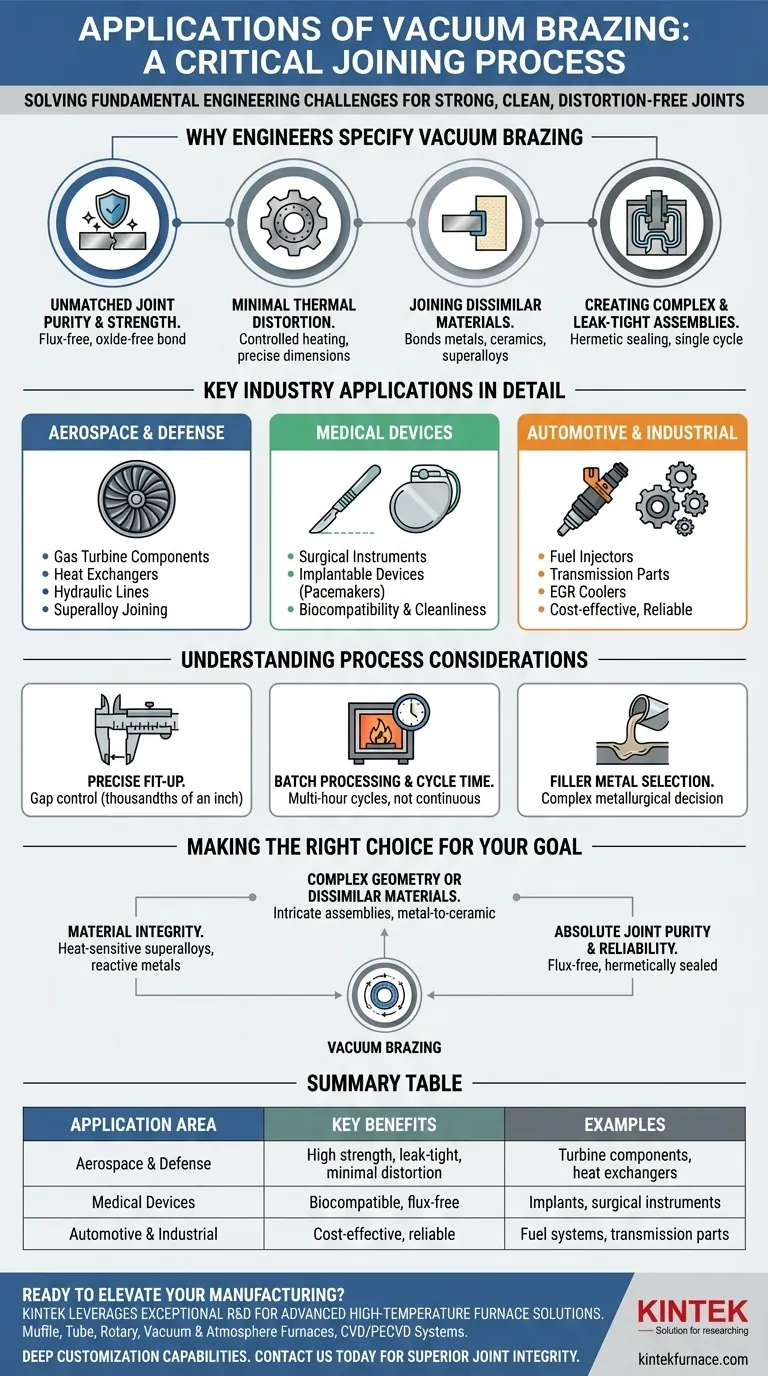

Why Engineers Specify Vacuum Brazing

Vacuum brazing is chosen when the integrity of the final assembly is non-negotiable. Its advantages stem directly from the physics of performing the process inside a high-vacuum furnace.

Unmatched Joint Purity and Strength

The process occurs in a controlled vacuum, an environment free from oxygen and other contaminants. This completely prevents the formation of oxides during heating, resulting in an exceptionally clean, strong metallurgical bond.

Because it is a flux-free process, there is zero risk of corrosive flux being trapped within the joint, a common point of failure in other brazing methods.

Minimal Thermal Distortion

Vacuum furnaces allow for precise, uniform heating and controlled cooling of the entire assembly. This managed thermal cycle minimizes internal stresses, preventing the warping and distortion that often plague welded parts.

This is critical for components with tight dimensional tolerances.

Joining Dissimilar and Sensitive Materials

Vacuum brazing excels where welding fails, particularly in joining materials with different properties. It is routinely used to create strong bonds between stainless steel, nickel superalloys, titanium, copper, and even non-metals like ceramics.

This capability is essential for creating components that leverage the unique properties of multiple materials in a single, integrated part.

Creating Complex and Leak-Tight Assemblies

The filler metal, drawn by capillary action, flows into tight-fitting joints throughout an entire assembly in a single furnace cycle. This allows for the creation of intricate and multi-jointed components that would be impractical to weld.

This process produces hermetically sealed joints, making it the standard for critical fuel, hydraulic, and vacuum system components where any leak would be catastrophic.

Key Industry Applications in Detail

The unique benefits of vacuum brazing make it indispensable across several advanced manufacturing sectors.

Aerospace and Defense

This is the quintessential application for vacuum brazing. It is used for gas turbine engine components, heat exchangers, and hydraulic lines. The process is vital for joining high-temperature superalloys without altering their metallurgy and ensuring absolute reliability.

Components must withstand extreme temperatures and pressures while remaining lightweight and fatigue-resistant, a standard that vacuum brazing consistently meets.

Medical Devices

In medical manufacturing, biocompatibility and cleanliness are paramount. Vacuum brazing is used to assemble surgical instruments and implantable devices, such as pacemakers and orthopedic implants.

The flux-free nature of the joint ensures no harmful residues are left behind, and its ability to join materials like titanium and stainless steel is critical for device performance.

Automotive and Industrial

While often seen as a high-end process, vacuum brazing is also cost-effective for producing critical automotive components in high volumes. Applications include fuel injectors, transmission parts, and EGR coolers.

The process delivers the high strength and leak-proof performance required for modern engine and drivetrain systems, often more efficiently than complex welding procedures.

Understanding the Process Considerations

While powerful, vacuum brazing is a specific tool for specific challenges. Understanding its operational realities is key to using it effectively.

The Need for Precise Fit-Up

Vacuum brazing relies entirely on capillary action to distribute the filler metal. This means the gap between the parts to be joined must be carefully engineered and controlled, typically within a few thousandths of an inch.

Poor fit-up will result in an incomplete or weak joint.

Batch Processing and Cycle Time

A vacuum furnace operates in batches. A full cycle of loading, pumping down to vacuum, heating, brazing, and cooling can take several hours.

This batch nature means it is not a continuous process like an automated welding line, a factor that must be considered in production planning.

Filler Metal Selection is Critical

The choice of brazing filler alloy is a complex decision. It must have a melting point lower than the parent materials, be compatible with them, and meet the performance requirements of the final assembly (e.g., strength, corrosion resistance).

This often requires metallurgical expertise to ensure a successful outcome.

Making the Right Choice for Your Goal

Selecting a joining process depends entirely on the engineering priorities of your project.

- If your primary focus is material integrity: Specify vacuum brazing for heat-sensitive superalloys or reactive metals like titanium to prevent oxidation and preserve their mechanical properties.

- If your primary focus is complex geometry or dissimilar materials: This is the ideal method for joining intricate assemblies or combinations like metal-to-ceramic that welding cannot handle.

- If your primary focus is absolute joint purity and reliability: For medical, aerospace, or vacuum applications requiring flux-free, hermetically sealed joints, vacuum brazing is the definitive choice.

By understanding its core principles, you can leverage vacuum brazing not just as a joining method, but as a strategic tool for advanced engineering design.

Summary Table:

| Application Area | Key Benefits |

|---|---|

| Aerospace & Defense | High strength, leak-tight joints, minimal distortion for superalloys |

| Medical Devices | Biocompatible, flux-free bonds for implants and instruments |

| Automotive & Industrial | Cost-effective, reliable assemblies for fuel systems and parts |

Ready to elevate your manufacturing with precision vacuum brazing solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for industries like aerospace, medical, and automotive. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental and production needs. Contact us today to discuss how we can help you achieve superior joint integrity and efficiency!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What does the vacuum system of a vacuum furnace consist of? Essential Components for Clean Heat Processing

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity