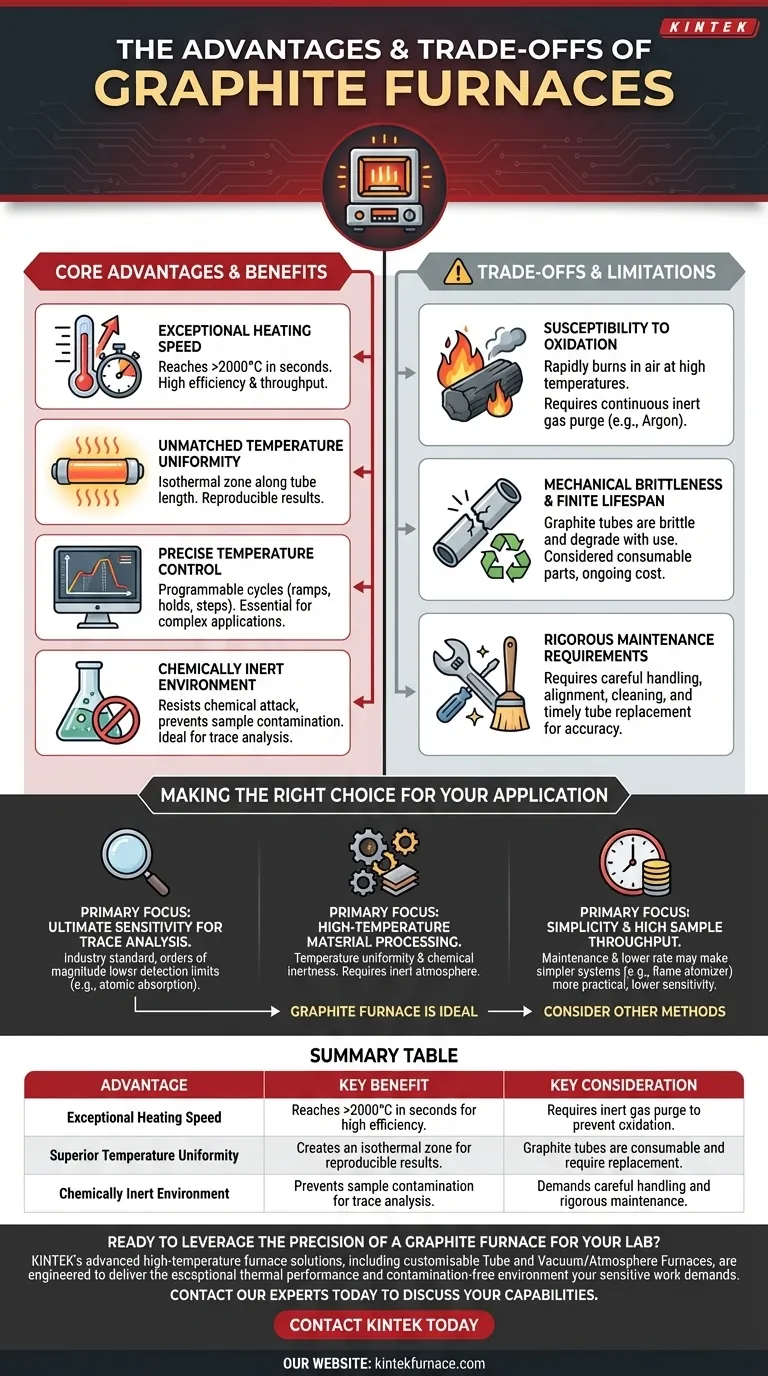

At its core, a graphite furnace offers significant advantages in high-temperature applications due to its exceptional heating speed, precise controllability, and superior temperature uniformity. It creates a chemically inert environment, which is critical for preventing contamination when analyzing trace elements or processing reactive materials.

A graphite furnace delivers unparalleled analytical sensitivity and thermal control, but this performance is directly tied to managing its specific operational requirements, namely its finite lifespan and susceptibility to oxidation.

Why Graphite Excels as a Heating Element

The unique physical properties of graphite make it a premier material for specialized heating applications, particularly in analytical chemistry and materials science.

Exceptional Heating Speed

Graphite has a low thermal mass and high electrical resistance, allowing a graphite furnace to reach extremely high temperatures (often >2000°C) in a matter of seconds. This rapid heating is a major advantage for efficiency and sample throughput.

Unmatched Temperature Uniformity

The typical design of a graphite furnace is a small, hollow tube. This structure creates an isothermal (uniform temperature) zone along its length, ensuring the entire sample is heated evenly and consistently. This uniformity is critical for reproducible results.

Precise Temperature Control

The rapid thermal response allows for highly precise and programmable heating cycles. Users can define complex temperature ramps, holds, and steps, which are essential for drying, ashing, and atomizing a sample in atomic absorption spectroscopy.

The Advantage of a Chemically Inert Environment

Beyond its thermal properties, graphite's chemical stability provides a distinct advantage in creating a clean, non-reactive chamber.

Preventing Sample Contamination

Graphite is highly resistant to chemical attack from a wide range of acids, bases, and melts. This inertness ensures that the furnace itself does not leach impurities into the sample, which is vital when measuring elements at parts-per-billion concentrations.

Ideal for Vacuum and Reactive Materials

In vacuum furnaces, graphite's stability and low vapor pressure at high temperatures make it an ideal choice. Its non-reactive nature is also crucial when processing materials that would otherwise react with metallic heating elements.

Understanding the Trade-offs and Limitations

The advantages of a graphite furnace are coupled with operational realities that must be understood and managed for successful use.

Susceptibility to Oxidation

Graphite will rapidly burn away (oxidize) in the presence of air at high temperatures. To prevent this, a graphite furnace must be continuously purged with an inert gas, typically argon, to protect the graphite tube.

Mechanical Brittleness and Finite Lifespan

Graphite tubes are inherently brittle and degrade with each heating cycle. They are considered consumable parts that must be replaced regularly to ensure consistent performance. This represents an ongoing operational cost.

Rigorous Maintenance Requirements

Achieving the benefits of a graphite furnace requires careful handling and consistent maintenance. Proper alignment, cleaning, and timely replacement of the graphite tube are necessary to maintain analytical accuracy and precision.

Making the Right Choice for Your Application

The decision to use a graphite furnace depends entirely on your specific analytical or processing goals.

- If your primary focus is ultimate sensitivity for trace element analysis: The graphite furnace is the industry standard, offering detection limits orders of magnitude lower than other methods like flame atomic absorption.

- If your primary focus is high-temperature material processing: The combination of temperature uniformity and chemical inertness is ideal, provided you can implement the necessary inert atmosphere to protect the heating elements.

- If your primary focus is simplicity and high sample throughput: The maintenance and lower sample-per-hour rate of a graphite furnace may make a simpler system, like a flame atomizer, a more practical choice, despite its lower sensitivity.

Understanding these fundamental principles empowers you to leverage the graphite furnace's power while effectively managing its operational demands.

Summary Table:

| Advantage | Key Benefit | Key Consideration |

|---|---|---|

| Exceptional Heating Speed | Reaches >2000°C in seconds for high efficiency. | Requires inert gas purge to prevent oxidation. |

| Superior Temperature Uniformity | Creates an isothermal zone for reproducible results. | Graphite tubes are consumable and require replacement. |

| Chemically Inert Environment | Prevents sample contamination for trace analysis. | Demands careful handling and rigorous maintenance. |

Ready to leverage the precision of a graphite furnace for your lab?

KINTEK's advanced high-temperature furnace solutions, including our customisable Tube and Vacuum/Atmosphere Furnaces, are engineered to deliver the exceptional thermal performance and contamination-free environment your sensitive work demands. Our strong in-house R&D and manufacturing capabilities ensure we can precisely tailor a system to your unique experimental requirements.

Contact our experts today to discuss how we can enhance your analytical or materials processing capabilities.

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency