In short, vacuum and modified atmosphere furnaces are essential for 3D printing because they create the highly controlled environment required to transform a fragile, porous printed object into a strong, fully dense, and dimensionally accurate final part. This post-processing step, known as sintering, is impossible to perform correctly in a standard atmosphere, where high heat would cause catastrophic oxidation and ruin the component's material properties.

The 3D printer only builds the shape; the furnace is what creates the final material. For high-performance metals and ceramics, heat treatment in a controlled atmosphere is not an optional add-on but a mandatory step to fuse particles, eliminate internal voids, and achieve the required strength and density.

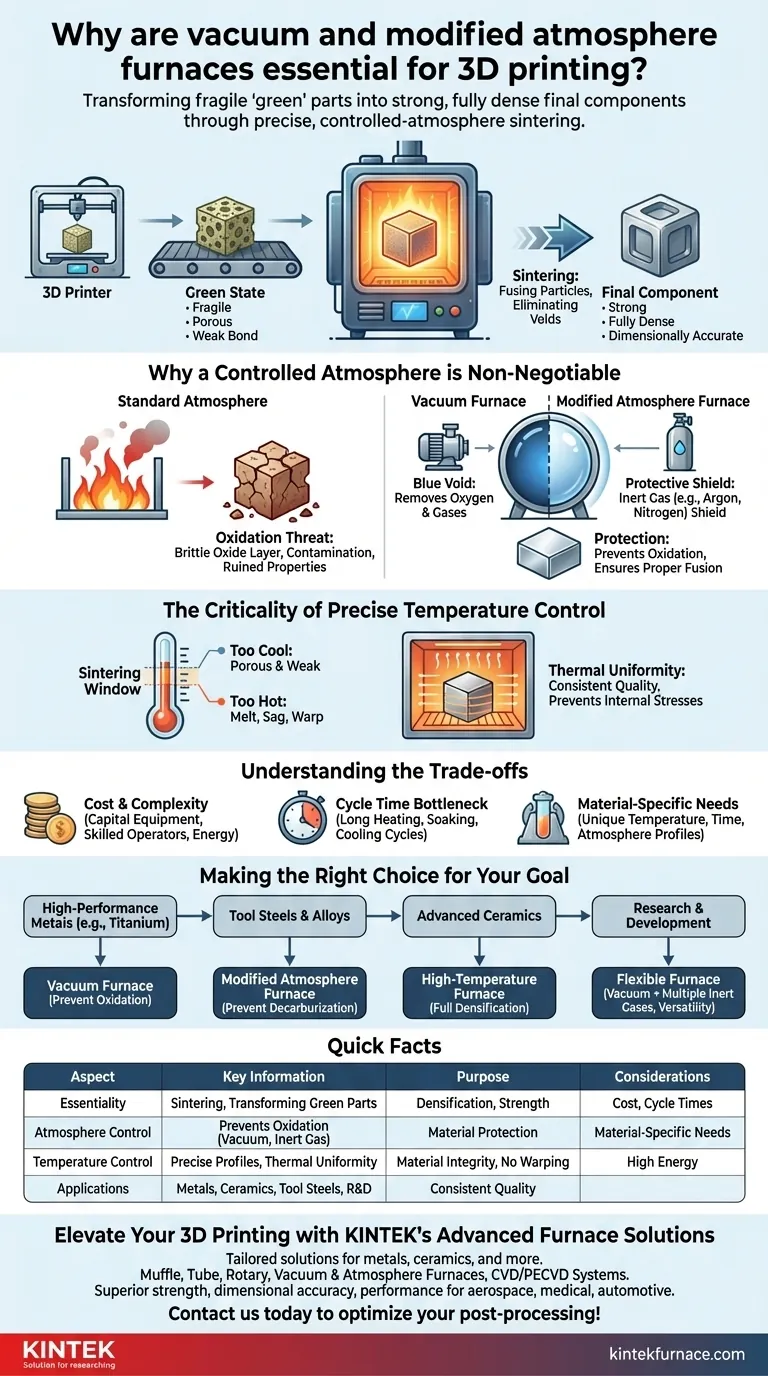

From "Green" Part to Final Component

A part fresh off a metal or ceramic 3D printer is not ready for use. It exists in a "green" state, where material particles are only lightly bound together. The furnace is where this green part matures into a functional component.

The Green State: A Fragile Beginning

The initial printed object has the correct shape but is mechanically weak and porous. It's essentially a compacted powder that you could easily break by hand. It lacks the density and structural integrity for any real-world application.

Sintering: Fusing Particles into a Solid

Sintering is a thermal process where the green part is heated to a high temperature, just below its melting point. This intense heat causes the individual material particles to bond and fuse, drastically reducing the porosity and increasing the part's density. The result is a solid, strong component with the desired metallurgical properties.

Why a Controlled Atmosphere is Non-Negotiable

Simply heating a part in an open-air oven would be disastrous. The atmosphere must be precisely managed to protect the material during the high-temperature sintering cycle. This is the primary function of a vacuum or modified atmosphere furnace.

The Threat of Oxidation

At the extreme temperatures required for sintering (often over 1200°C), most metals react aggressively with oxygen. This reaction, oxidation, forms a brittle oxide layer that contaminates the material, prevents proper particle fusion, and severely degrades its strength and performance.

Vacuum: Removing the Enemy

The most effective way to prevent oxidation is to remove the oxygen entirely. A vacuum furnace pumps out the air and other atmospheric gases before the heating cycle begins. This ultra-pure environment is critical for highly reactive materials like titanium and aluminum, ensuring the final part is free from contamination.

Modified Atmospheres: Adding a Protective Shield

In other cases, it's beneficial to introduce a specific gas. A modified atmosphere furnace first creates a vacuum and then backfills the chamber with a controlled amount of an inert gas like Argon or Nitrogen. These gases act as a protective shield, preventing unwanted chemical reactions while enabling consistent heat transfer.

The Criticality of Precise Temperature Control

Controlling the atmosphere is only half the battle. The temperature profile of the sintering cycle must be executed with extreme precision.

The Narrow Sintering Window

Every material has an optimal "sintering window"—a narrow temperature range for ideal fusion.

- Too cool: The part will not fully densify, leaving it porous and weak.

- Too hot: The part can melt, sag, or warp, destroying its dimensional accuracy.

Thermal Uniformity for Consistent Quality

A high-quality furnace provides exceptional thermal uniformity, meaning the temperature is consistent across the entire part. This prevents one area from heating faster than another, which could cause internal stresses, warping, or inconsistent density. For components used in aerospace, medical, or automotive applications, this consistency is an absolute requirement.

Understanding the Trade-offs

While essential, these furnaces represent a significant investment and introduce process considerations that must be managed.

Cost and Complexity

Vacuum and modified atmosphere furnaces are specialized, high-cost capital equipment. They require skilled operators, regular maintenance, and significant energy consumption, all of which contribute to the final cost per part.

Cycle Time as a Bottleneck

Sintering is not a fast process. A single furnace cycle, including heating, soaking at temperature, and cooling, can take many hours or even a full day. This can become a bottleneck in a high-volume production workflow and must be planned for accordingly.

Material-Specific Needs

There is no one-size-fits-all furnace cycle. Each material—and even different alloys of the same metal—requires a unique profile of temperature, time, and atmospheric composition. Switching between materials can require significant process development and validation.

Making the Right Choice for Your Goal

Selecting the right heat treatment strategy depends entirely on your material and the performance requirements of the final component.

- If your primary focus is high-performance metals (e.g., Titanium, Inconel): A high-purity vacuum furnace is non-negotiable to prevent oxidation and achieve the necessary strength for critical applications.

- If your primary focus is tool steels or specialized alloys: A modified atmosphere furnace provides the control needed to prevent surface effects like decarburization, ensuring consistent hardness and wear resistance.

- If your primary focus is advanced ceramics: A high-temperature furnace with precise atmospheric control is essential to achieve full densification and the desired mechanical and thermal properties.

- If your primary focus is research and development: A flexible furnace supporting both vacuum and multiple inert gases offers the most versatility for experimenting with novel materials and processes.

Ultimately, investing in the right furnace technology is an investment in the final integrity, reliability, and performance of your 3D printed components.

Summary Table:

| Aspect | Key Information |

|---|---|

| Purpose | Essential for sintering to transform fragile 3D printed parts into dense, strong components. |

| Atmosphere Control | Prevents oxidation; vacuum removes oxygen, modified atmospheres use inert gases like Argon or Nitrogen. |

| Temperature Control | Precise thermal profiles ensure uniform heating, avoiding warping and ensuring material integrity. |

| Common Applications | High-performance metals (e.g., Titanium), ceramics, tool steels, and R&D for consistent quality. |

| Considerations | High cost, long cycle times, and material-specific requirements for optimal results. |

Elevate Your 3D Printing with KINTEK's Advanced Furnace Solutions

Are you struggling with weak, porous 3D printed parts? KINTEK specializes in high-temperature furnace technology to transform your prototypes into robust, fully dense components. Leveraging exceptional R&D and in-house manufacturing, we provide tailored solutions like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise sintering for metals, ceramics, and more, delivering superior strength, dimensional accuracy, and performance for industries like aerospace, medical, and automotive. Don't let oxidation or inconsistent heating hold you back—contact us today to discuss how our furnaces can optimize your post-processing and boost your production efficiency!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- How does the inert atmosphere heat treating process work? Prevent Oxidation for Superior Material Quality

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- How does a chemically inert atmosphere function in a furnace? Prevent Oxidation and Ensure Material Purity

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity

- What is nitrogen used for in a furnace? Prevent Oxidation and Control Heat Treatment Quality