To ensure the structural integrity of AlCrSiWN coatings, the vacuum pumping system must achieve a base vacuum level below 3x10⁻³ Pa. This specific threshold is critical for creating an environment free of contaminants that could otherwise compromise the deposition process.

By maintaining a high-vacuum environment below 3x10⁻³ Pa, you prevent unwanted chemical reactions and guarantee both the purity of the coating composition and its bonding strength to the substrate.

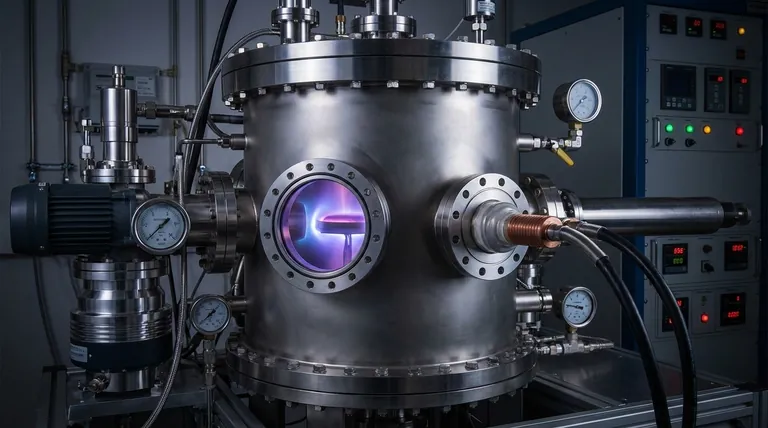

The Critical Role of High Vacuum in Deposition

Eliminating Contaminants

The primary objective of reaching a pressure below 3x10⁻³ Pa is the total evacuation of residual air molecules and impurity gases from the furnace chamber.

If these gases remain present, they become active variables in what should be a controlled environment.

Preventing Unwanted Reactions

During the vapor deposition process, the chemistry of the coating is highly sensitive.

A high-vacuum environment prevents unwanted chemical reactions between the coating materials and residual atmosphere. This ensures that the AlCrSiWN layer forms exactly as chemically intended, without oxidation or contamination.

Ensuring Adhesion and Purity

The quality of the final product relies on two physical properties: bonding strength and compositional purity.

The vacuum removes barriers between the coating and the substrate, allowing for superior adhesion. Simultaneously, it ensures the coating retains its intended purity, which is essential for performance.

Operational Implications and Equipment Selection

Identifying the Vacuum Range

It is important to categorize your equipment needs correctly. A target of 3x10⁻³ Pa places your operation firmly in the "high vacuum" range (comparable to the 10⁻⁵ Torr range).

This is distinct from "soft vacuum" applications (low micron level), where requirements are far less stringent.

Pumping System Requirements

Because this process requires high vacuum, standard equipment often falls short.

While a mechanical pump or blower is sufficient for soft vacuums, they cannot achieve the low pressures required for AlCrSiWN deposition. You must utilize a diffusion or turbomolecular pumping system to reliably reach and maintain the necessary base vacuum.

Making the Right Choice for Your Goal

To secure the quality of your coating, align your equipment and protocols with these standards:

- If your primary focus is coating adhesion: rigorous adherence to the 3x10⁻³ Pa limit is required to remove gas layers that inhibit bonding.

- If your primary focus is equipment selection: ensure your specification includes diffusion or turbomolecular pumps, as mechanical pumps alone will fail to reach the required baseline.

Strict control of the vacuum environment is the single most effective variable for ensuring a high-performance, durable coating.

Summary Table:

| Feature | Requirement | Impact on Coating Quality |

|---|---|---|

| Target Vacuum Level | Below 3x10⁻³ Pa | Prevents oxidation and ensures high purity |

| Vacuum Category | High Vacuum | Necessary for advanced vapor deposition |

| Recommended Pump | Diffusion or Turbomolecular | Reaches base pressures mechanical pumps cannot |

| Key Outcome | Enhanced Adhesion | Removes gas barriers for better substrate bonding |

Elevate Your Coating Precision with KINTEK

Don’t let residual contaminants compromise your AlCrSiWN deposition. Backed by expert R&D and manufacturing, KINTEK offers high-performance vacuum systems, including CVD, Muffle, and customizable lab high-temp furnaces tailored for high-vacuum applications. Our specialized systems are designed to reliably reach the sub-3x10⁻³ Pa levels your advanced materials demand.

Ready to optimize your thin-film quality? Contact us today to discuss your unique deposition needs and discover how our precision engineering can enhance your laboratory’s efficiency.

Visual Guide

References

- Feng Guo. Research on the Performance of AlCrSiWN Tool Coatings for Hardened Steel Cutting. DOI: 10.62051/ijmee.v6n2.01

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

People Also Ask

- What are the key advantages of using a vacuum sintering furnace? Achieve High-Purity, Dense Materials with Superior Control

- What is furnace brazing and how does it work? Achieve Strong, Clean Metal Joints with Precision

- How does a vacuum furnace ensure high-quality output? Achieve Superior Purity and Performance for Your Materials

- Why is an industrial vacuum drying oven essential for ceramic precursors? Preserve Material Purity and Stoichiometry

- What role does an LTGN vacuum furnace play in stainless steel modification? Master S-Phase Surface Hardening

- Why is the cooling system important in the furnace? Ensure Longevity, Efficiency, and Safety

- What materials are compatible with high vacuum furnaces? Essential Guide for Aerospace, Medical, and Electronics

- How does heat transfer occur in a vacuum furnace? Master Thermal Radiation for Precise Lab Results