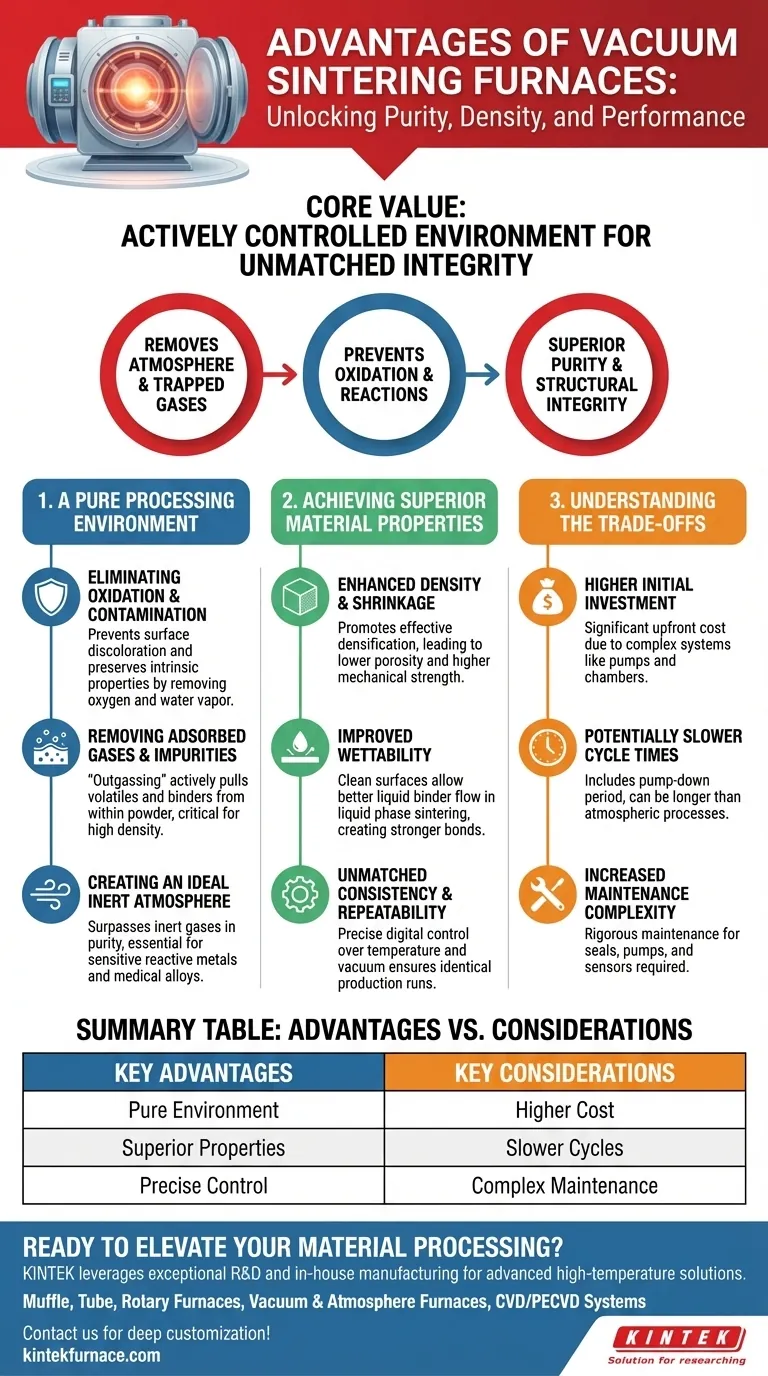

In short, the primary advantages of a vacuum sintering furnace are the ability to produce exceptionally pure, high-density materials with superior mechanical properties. By eliminating atmospheric gases, the furnace prevents oxidation and removes impurities, while enabling precise control over the entire heating and cooling cycle for unmatched consistency.

The core value of vacuum sintering is not just the absence of atmosphere, but the creation of an actively controlled environment. This allows you to prevent unwanted chemical reactions and physically remove trapped gases, resulting in a final product with a level of purity and structural integrity that is often unattainable with other methods.

The Foundational Advantage: A Pure Processing Environment

The defining characteristic of a vacuum furnace is its ability to remove the atmosphere—and all the problems that come with it. This creates an ideal environment for processing sensitive materials.

Eliminating Oxidation and Contamination

In a conventional furnace, ambient oxygen and water vapor react with the material's surface, creating oxide layers. A vacuum furnace physically removes these reactive gases.

This prevents oxidation, hydrogenation, and nitridation, ensuring the material's intrinsic properties are preserved. The result is a clean, bright part free from surface discoloration and contamination.

Removing Adsorbed Gases and Impurities

The sintering process is not just about the external atmosphere; it's also about what's trapped inside the powdered material.

The vacuum actively pulls adsorbed gases and volatile impurities (like residual lubricants or binders) out from between the powder particles. This "outgassing" is critical for achieving high final density.

Creating an Ideal Inert Atmosphere

While inert gas furnaces (using Argon or Nitrogen) also prevent oxidation, a vacuum is often considered the purest possible environment.

Even high-purity bottled gases contain trace amounts of contaminants. A vacuum avoids this issue entirely, making it the superior choice for materials with extreme sensitivity to impurities, such as reactive metals or medical-grade alloys.

Achieving Superior Material Properties

This highly controlled, pure environment directly translates into improved physical and mechanical characteristics in the final sintered component.

Enhanced Density and Shrinkage

By removing trapped gases that would otherwise be caught in pores, a vacuum promotes more effective densification and shrinkage during the later stages of sintering.

This leads to parts with lower porosity and higher density, which are directly correlated with improved mechanical strength, hardness, and fatigue resistance.

Improved Wettability for Liquid Phase Sintering

In liquid phase sintering, a binder metal melts and flows into the gaps between solid particles. Oxide films on the particle surfaces inhibit this flow, a phenomenon known as poor wettability.

Because a vacuum furnace produces atomically clean surfaces, the liquid binder can wet and spread far more effectively. This creates stronger bonds and a more uniform microstructure throughout the component.

Unmatched Consistency and Repeatability

Modern vacuum furnaces offer exceptionally precise process control. Advanced digital systems manage temperature, vacuum levels, and gas flow with high accuracy.

This tight control over every variable, combined with the stable vacuum environment, ensures that each production run is nearly identical. This metallurgical repeatability is essential for applications in aerospace, medical, and other high-stakes industries.

Understanding the Trade-offs

While powerful, vacuum sintering is not the universal solution. Acknowledging its limitations is key to making an informed decision.

Higher Initial Investment

Vacuum furnaces are complex machines involving vacuum pumps, sophisticated control systems, and robust chamber construction. This results in a significantly higher upfront capital cost compared to traditional atmospheric furnaces.

Potentially Slower Cycle Times

Achieving a deep vacuum requires a "pump-down" period, which adds time to the overall process cycle. While rapid cooling or "quenching" is a key feature, the total time from loading to unloading can be longer than for some atmospheric processes.

Increased Maintenance Complexity

High-vacuum systems demand rigorous maintenance schedules. Seals, pumps, and sensors must be regularly inspected and serviced to ensure the integrity of the vacuum and prevent costly downtime.

Making the Right Choice for Your Application

Selecting the right furnace technology depends entirely on your material requirements and project goals.

- If your primary focus is reactive or high-purity materials: Vacuum sintering is non-negotiable for preventing the contamination and oxidation that would compromise materials like titanium, superalloys, and medical implants.

- If your primary focus is maximum mechanical performance: The enhanced densification and defect-free microstructure achieved in a vacuum furnace are critical for producing high-strength cemented carbides, ceramics, and structural metal parts.

- If your primary focus is complex geometries or liquid phase sintering: The superior surface cleanliness provided by a vacuum ensures excellent binder flow and bonding, enabling the successful production of intricate and reliable components.

Ultimately, choosing a vacuum sintering furnace is an investment in process control, material purity, and the final performance of your component.

Summary Table:

| Advantage | Description |

|---|---|

| Pure Processing Environment | Eliminates oxidation and contamination by removing atmospheric gases, ensuring material purity. |

| Superior Material Properties | Enhances density, shrinkage, and wettability for improved strength and consistency. |

| Precise Process Control | Offers unmatched repeatability with advanced digital systems for temperature and vacuum management. |

| Trade-offs | Higher initial cost, slower cycle times, and increased maintenance complexity. |

Ready to elevate your material processing with precision and purity? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored to your unique needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities. Whether you're working with reactive metals, medical-grade alloys, or complex geometries, our vacuum sintering furnaces can help you achieve superior results. Contact us today to discuss how we can support your laboratory's goals with reliable, high-performance equipment!

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- What processing conditions does a vacuum furnace provide for TiCp/Fe microspheres? Sintering at 900 °C

- What is the purpose of performing medium vacuum annealing on working ampoules? Ensure Pure High-Temp Diffusion

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity