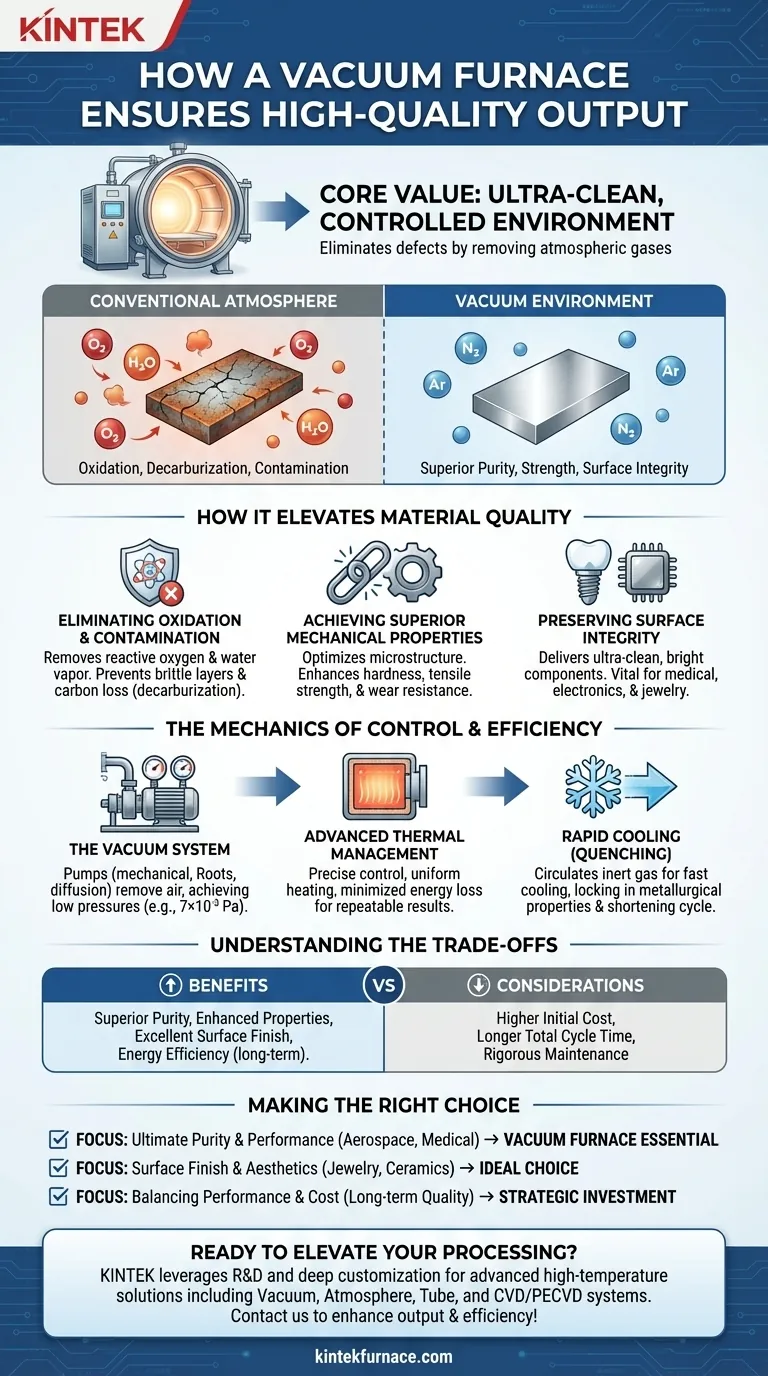

Fundamentally, a vacuum furnace ensures high-quality output by creating an ultra-clean, controlled environment. By pumping out nearly all atmospheric gases before heating, it eliminates the root cause of many material defects: unwanted chemical reactions. This prevents oxidation, decarburization, and general contamination, resulting in finished parts with superior purity, strength, and surface integrity compared to those processed in open air.

The core value of a vacuum furnace is not merely heating a material, but precisely controlling its chemical environment. By removing reactive gases, you unlock a level of material purity and performance that is physically impossible to achieve in conventional atmospheric processes.

How a Vacuum Environment Elevates Material Quality

The primary function of the vacuum is to create an inert space. This seemingly simple act has profound effects on the material being processed.

Eliminating Oxidation and Contamination

The air around us is rich in oxygen and water vapor, which are highly reactive at elevated temperatures. A vacuum furnace removes these reactive elements.

This prevents oxidation, a process that can form a brittle, discolored layer on a material's surface. It also prevents decarburization in steels, which is the loss of carbon content from the surface, leading to reduced hardness and fatigue strength.

Achieving Superior Mechanical Properties

Because the material is not compromised by unwanted reactions, its intrinsic properties can be fully realized and even enhanced.

Heat treating in a vacuum allows for the development of optimal microstructures. This leads to measurable improvements in hardness, tensile strength, and wear resistance, which are critical for high-performance applications in aerospace, medical, and tooling industries.

Preserving Surface Integrity

Many processes require a final part that is not only strong but also clean, bright, and free of surface defects. The vacuum environment is essential for this.

By preventing reactions, the furnace delivers ultra-clean components with minimal surface irregularities. This is particularly vital for products like medical implants, precision electronics, and high-end jewelry made from precious metals, where both function and aesthetics are paramount.

The Mechanics of Control and Efficiency

A modern vacuum furnace is more than just a heated box with a pump. It is a sophisticated system designed for precision, repeatability, and efficiency.

The Vacuum System

The goal is to achieve a specific level of vacuum, measured in units like Pascals (Pa). This is accomplished with a series of pumps, often including mechanical pumps, Roots pumps, and diffusion pumps, which work together to remove air from the sealed chamber.

A high-vacuum furnace can reach pressures as low as 7×10⁻³ Pa, effectively creating a near-perfectly inert environment for processing.

Advanced Thermal Management

Modern furnaces use advanced insulation materials and sophisticated control systems to ensure uniform heating and minimize energy loss.

This precise thermal control allows for complex, multi-stage heating cycles with exceptional accuracy, ensuring every part in a batch receives the exact same treatment. This also optimizes energy consumption, reducing operational costs.

Rapid Cooling (Quenching)

Many vacuum furnaces integrate a rapid cooling or quenching capability. After the heating cycle, an inert gas like nitrogen or argon can be rapidly circulated through the chamber.

This shortens the overall process cycle time and allows for specific metallurgical properties to be "locked in," further enhancing the material's final characteristics.

Understanding the Trade-offs

While powerful, a vacuum furnace is not the universal solution for all heating applications. Its benefits come with practical considerations.

Higher Initial Cost and Complexity

Vacuum furnaces are sophisticated machines with complex pumping systems, seals, and controls. This results in a higher initial capital investment compared to standard atmospheric furnaces. Operation and programming also require more specialized training.

Process Cycle Time

While quenching is fast, the initial step of pumping the chamber down to the required vacuum level takes time. For some simple, low-tolerance applications, the total cycle time may be longer than in a conventional furnace.

Maintenance Requirements

The high-performance components, especially the vacuum pumps, seals, and sensors, require a rigorous and consistent maintenance schedule. A small leak can compromise the entire process, making upkeep a critical factor for reliable operation.

Making the Right Choice for Your Application

Selecting the right thermal processing technology depends entirely on your final goal for the material.

- If your primary focus is ultimate material purity and performance: A vacuum furnace is non-negotiable for sensitive alloys used in aerospace, medical, or high-end electronics where contamination can lead to failure.

- If your primary focus is surface finish and aesthetics: A vacuum furnace is the ideal choice for applications like jewelry, dental ceramics, or decorative components, as it produces bright, clean parts without secondary cleaning.

- If your primary focus is balancing performance and cost: A vacuum furnace represents a long-term investment in quality. The higher initial cost can be offset by lower part rejection rates, superior material properties, and increased energy efficiency.

Ultimately, a vacuum furnace is an investment in absolute process control, enabling you to achieve material properties that are simply not possible in a conventional atmosphere.

Summary Table:

| Key Aspect | Description |

|---|---|

| Eliminates Oxidation | Removes oxygen and water vapor to prevent surface defects and brittleness. |

| Prevents Contamination | Creates an inert environment, avoiding decarburization and impurities. |

| Enhances Mechanical Properties | Improves hardness, tensile strength, and wear resistance through controlled heating. |

| Preserves Surface Integrity | Produces clean, bright parts ideal for medical implants and precision electronics. |

| Advanced Control | Uses vacuum systems and thermal management for precise, repeatable results. |

Ready to elevate your material processing with precision and purity? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Vacuum & Atmosphere Furnaces, Muffle, Tube, Rotary Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs, delivering superior quality for industries like aerospace, medical, and tooling. Contact us today to discuss how our vacuum furnaces can enhance your output and efficiency!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion