Furnace brazing is a high-precision metal joining process that uses a controlled-atmosphere furnace to heat multiple components and a filler metal. The furnace brings the assembly to a temperature high enough to melt the filler metal, but not the base components. The molten filler then flows into the tight gaps between the parts via capillary action, creating a strong, clean, and permanent metallurgical bond upon cooling.

The core value of furnace brazing isn't just joining parts; it's the ability to create exceptionally strong, clean, and distortion-free joints in complex assemblies, something often unattainable with conventional welding or torch brazing.

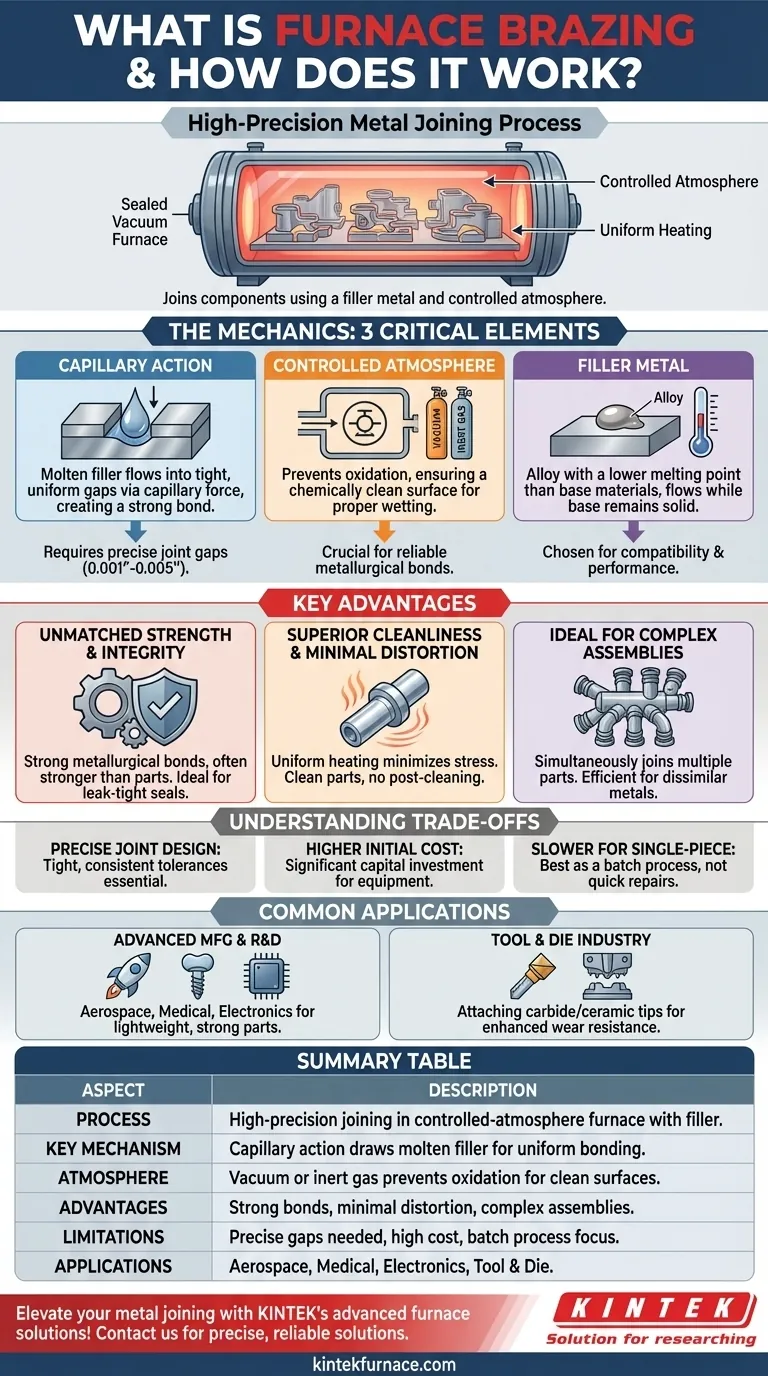

The Mechanics of the Brazing Process

Understanding how furnace brazing works requires looking at three critical elements: the force that draws the metal, the environment it's created in, and the material that forms the bond.

The Role of Capillary Action

Capillary action is the fundamental force that makes brazing possible. It is the tendency of a liquid to be drawn into a narrow space without the assistance of, or even in opposition to, external forces like gravity.

For this to work effectively, the parts being joined must be designed with a very specific, uniform gap between them. When the filler metal melts inside the furnace, this narrow gap pulls the liquid into the entire joint, ensuring complete coverage.

The Importance of the Controlled Atmosphere

Furnace brazing takes place in a sealed chamber, typically either a vacuum or an environment filled with an inert gas. This controlled atmosphere is critical for preventing the oxidation of the metal surfaces at high temperatures.

An oxidized surface prevents the filler metal from properly "wetting" the base materials, which would result in a weak or failed joint. The controlled atmosphere ensures a chemically clean surface, leading to a strong, reliable metallurgical bond.

The Filler Metal: The Key Ingredient

The filler metal, or braze alloy, is a metal alloy with a melting point lower than the base materials being joined. It is chosen based on its compatibility with the base materials and the performance requirements of the final assembly.

When the furnace reaches the designated temperature, the filler melts and flows, while the much stronger base components remain solid and stable.

Why Choose Furnace Brazing? Key Advantages

Furnace brazing is selected when the quality and integrity of the joint are paramount. It offers distinct benefits over other joining methods.

Unmatched Joint Strength and Integrity

Because the filler metal forms a metallurgical bond with the base materials, the resulting joint is exceptionally strong and often stronger than the individual parts. The process is ideal for creating leak-tight seals required in high-performance applications.

Superior Cleanliness and Minimal Distortion

The uniform heating and cooling inside a furnace minimizes the thermal stress and distortion common in welding, where heat is applied locally. The protective atmosphere also produces bright, clean parts that often require no post-process cleaning.

Ideal for Complex Assemblies

Furnace brazing allows multiple joints on a single complex assembly to be created simultaneously. This is highly efficient compared to joining each part one by one. It is also an excellent method for joining dissimilar metals that cannot be effectively welded.

Understanding the Trade-offs

Despite its advantages, furnace brazing is not the right solution for every situation. Objectivity requires acknowledging its limitations.

Requirement for Precise Joint Design

The process is entirely dependent on capillary action, which only works if the gap between the parts is small and consistent (typically 0.001" to 0.005"). This requires a higher degree of precision in manufacturing the individual components.

Higher Initial Equipment Cost

Industrial vacuum furnaces and the associated control systems represent a significant capital investment. For low-volume or simple jobs, the cost can be prohibitive compared to more common welding or torch-brazing setups.

Slower for Single-Piece Work

Furnace brazing is a batch process. While it is highly efficient for running dozens or hundreds of parts at once, it is much slower than welding for a single, quick repair or one-off prototype.

Common Applications

The unique benefits of furnace brazing make it essential in several demanding industries.

Advanced Manufacturing and R&D

The process is widely used in aerospace, medical, and electronics manufacturing for creating components that must be both lightweight and incredibly strong. It is also used in research to test new materials and joining techniques under perfectly controlled conditions.

Tool and Die Industry

Furnace brazing is used to attach carbide or ceramic tips to cutting tools, molds, and dies. This enhances the hardness and wear resistance of the working surfaces, extending the tool's life and improving manufacturing efficiency.

Making the Right Choice for Your Application

Selecting the right joining process depends entirely on your project's specific engineering and business goals.

- If your primary focus is joining complex assemblies with high-integrity, leak-proof joints: Furnace brazing is the superior choice due to its uniform heating and clean, strong bonds.

- If your primary focus is maintaining material properties and minimizing part distortion: The controlled, lower-temperature thermal cycle of furnace brazing makes it ideal for delicate or precision parts.

- If your primary focus is rapid, low-cost joining for non-critical, simple parts: Conventional welding or torch brazing will likely be a more practical and cost-effective solution.

Ultimately, choosing furnace brazing is a deliberate engineering decision to achieve a level of quality and performance that other methods cannot provide.

Summary Table:

| Aspect | Description |

|---|---|

| Process | High-precision metal joining using a controlled-atmosphere furnace and filler metal. |

| Key Mechanism | Capillary action draws molten filler into tight gaps for uniform bonding. |

| Atmosphere | Vacuum or inert gas to prevent oxidation and ensure clean surfaces. |

| Advantages | Strong metallurgical bonds, minimal distortion, ideal for complex assemblies. |

| Limitations | Requires precise joint gaps, higher equipment cost, slower for single pieces. |

| Applications | Aerospace, medical, electronics, tool and die industries for high-performance parts. |

Elevate your metal joining capabilities with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our deep customization ensures precise solutions for your unique experimental needs, delivering strong, clean, and reliable joints for complex assemblies. Contact us today to discuss how our expertise can enhance your project's performance and efficiency!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- How does a mixed gas flow control system maintain stability during high-temperature nitriding? Precision Gas Ratios

- Can box type high-temperature resistance furnaces control the atmosphere? Unlock Precision in Material Processing

- What are the development prospects of atmosphere box furnaces in the aerospace industry? Unlock Advanced Material Processing for Aerospace Innovation

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas

- What are the key features of an atmosphere box furnace? Unlock Precise Heat Processing in Controlled Environments