The Low-Temperature Gaseous Nitriding (LTGN) vacuum furnace serves as a precision instrument for hardening the surface of austenitic stainless steel without compromising its corrosion resistance.

It operates by creating a controlled thermochemical environment, typically at 420°C, where nitrogen atoms are diffused into the steel’s surface. This process creates a hardened layer known as the "S-phase" (a supersaturated solid solution) while strictly maintaining temperatures below the threshold where the material's protective properties would degrade.

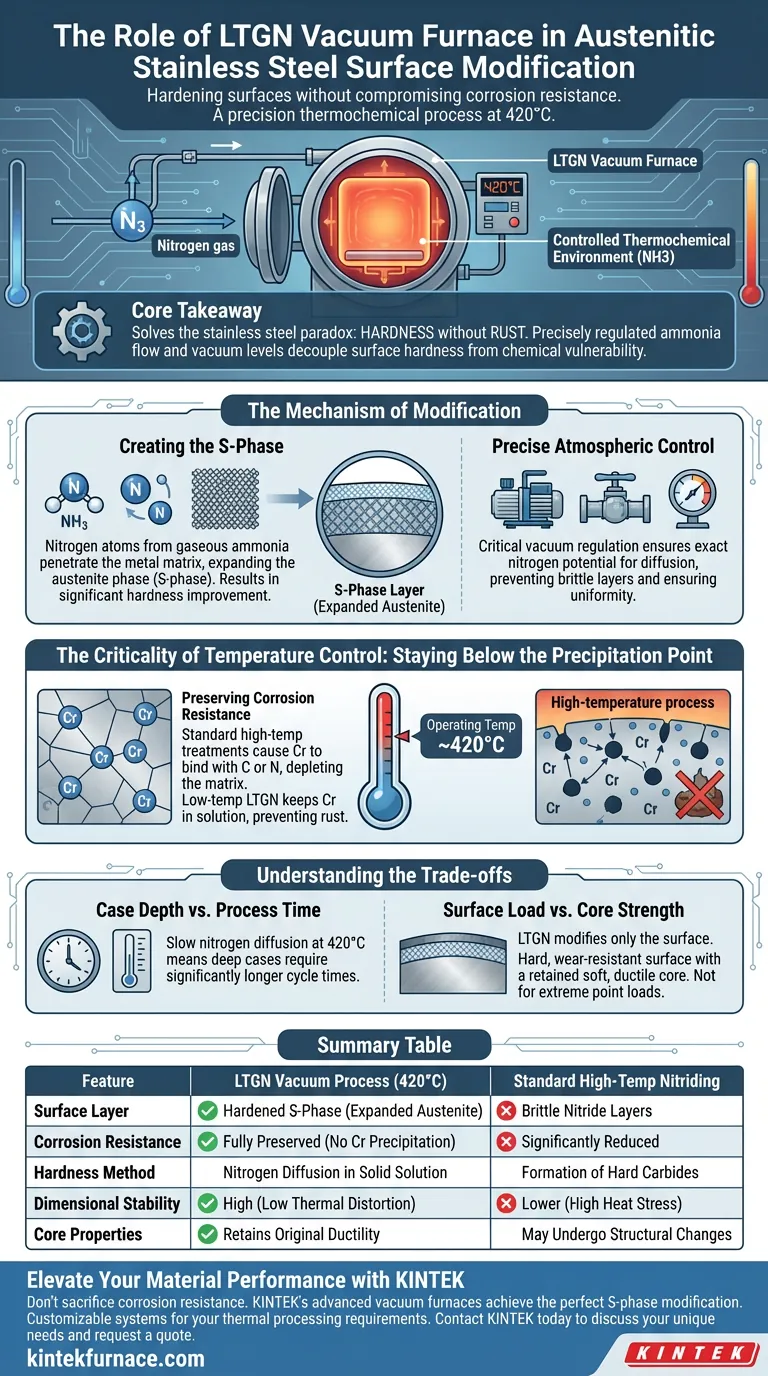

Core Takeaway The LTGN furnace solves the historical paradox of treating stainless steel: how to make it harder without making it rust. By precisely regulating ammonia flow and vacuum levels below the carbide precipitation point, it decouples surface hardness from chemical vulnerability.

The Mechanism of Modification

Creating the S-Phase

The furnace utilizes a gaseous ammonia (NH3) source to introduce nitrogen to the steel surface.

Unlike a coating that sits on top, the nitrogen atoms penetrate the metal matrix itself.

This results in the formation of an expanded austenite phase, often called the S-phase. This phase provides significant hardness improvements compared to the untreated base material.

Precise Atmospheric Control

The "vacuum" component of the LTGN system is critical for regulating the nitrogen potential.

By adjusting the vacuum levels and gas flow, the furnace ensures the exact amount of nitrogen is available for diffusion.

This prevents the formation of unwanted brittle layers and ensures a uniform surface modification.

The Criticality of Temperature Control

Staying Below the Precipitation Point

The defining feature of the LTGN process is its operating temperature, typically held around 420°C.

This specific temperature is chosen because it is below the critical point for chromium carbide precipitation.

Preserving Corrosion Resistance

In standard high-temperature treatments, chromium binds with carbon or nitrogen to form carbides.

This reaction depletes the surrounding matrix of chromium, which is the element responsible for preventing rust.

By keeping the process at low temperatures, the LTGN furnace ensures chromium remains in solution, preserving the stainless steel's inherent corrosion resistance.

Understanding the Trade-offs

Case Depth vs. Process Time

Because the process relies on diffusion at relatively low temperatures (420°C), the nitrogen moves slowly into the material.

Achieving a deep case depth requires significantly longer cycle times compared to high-temperature treatments.

Surface Load vs. Core Strength

The LTGN process modifies only the surface layer of the steel.

While the surface becomes extremely hard and wear-resistant, the core of the material retains its original softness and ductility.

This is beneficial for toughness but means the material cannot support extreme point loads that might deform the softer core beneath the hard shell.

Making the Right Choice for Your Goal

The LTGN furnace is a specialized tool optimized for specific engineering requirements.

- If your primary focus is wear resistance in corrosive environments: The LTGN process is ideal as it creates a hard S-phase surface while preventing chromium depletion.

- If your primary focus is dimensional stability: The low operating temperature (420°C) minimizes thermal distortion compared to higher temperature annealing or hardening processes.

Ultimately, the LTGN furnace allows you to engineer the surface properties of stainless steel independently of its bulk characteristics.

Summary Table:

| Feature | LTGN Vacuum Process (420°C) | Standard High-Temp Nitriding |

|---|---|---|

| Surface Layer | Hardened S-Phase (Expanded Austenite) | Brittle Nitride Layers |

| Corrosion Resistance | Fully Preserved (No Cr Precipitation) | Significantly Reduced |

| Hardness Method | Nitrogen Diffusion in Solid Solution | Formation of Hard Carbides |

| Dimensional Stability | High (Low Thermal Distortion) | Lower (High Heat Stress) |

| Core Properties | Retains Original Ductility | May Undergo Structural Changes |

Elevate Your Material Performance with KINTEK

Don't sacrifice corrosion resistance for surface hardness. KINTEK's advanced vacuum furnace technology allows you to achieve the perfect S-phase modification for austenitic stainless steel. Backed by expert R&D and world-class manufacturing, we provide customizable Muffle, Tube, Rotary, Vacuum, and CVD systems tailored to your precise thermal processing requirements.

Whether you need to improve wear resistance or ensure dimensional stability, our lab high-temp furnaces offer the precision control your project demands. Contact KINTEK today to discuss your unique needs and request a quote!

Visual Guide

References

- Jordan Maximov, Yaroslav Argirov. Improvement in Fatigue Strength of Chromium–Nickel Austenitic Stainless Steels via Diamond Burnishing and Subsequent Low-Temperature Gas Nitriding. DOI: 10.3390/app14031020

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering and Brazing Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Vacuum Tilt Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the advantages of multi-chamber continuous vacuum furnaces? Boost Efficiency in High-Volume Production

- What are the key benefits of vacuum brazing? Achieve Strong, Clean Joints for Complex Assemblies

- What are the main benefits of using a vacuum furnace for industrial processes? Achieve Superior Material Quality & Control

- What are the key characteristics of vacuum hardening? Achieve Clean, Precise Metal Hardening for Superior Components

- What materials are used in high-temperature vacuum furnace hot zones? Optimize Your Process with the Right Choice

- How does vacuum brazing prevent oxidation and contamination? Achieve Clean, Strong Joints for Critical Applications

- Why is a high vacuum level required for a thermal evaporator? Ensure Pure Transition Metal Oxide (TMO) Deposition

- Why is graphite the material of choice for vacuum furnaces? Unmatched Performance in Extreme Heat