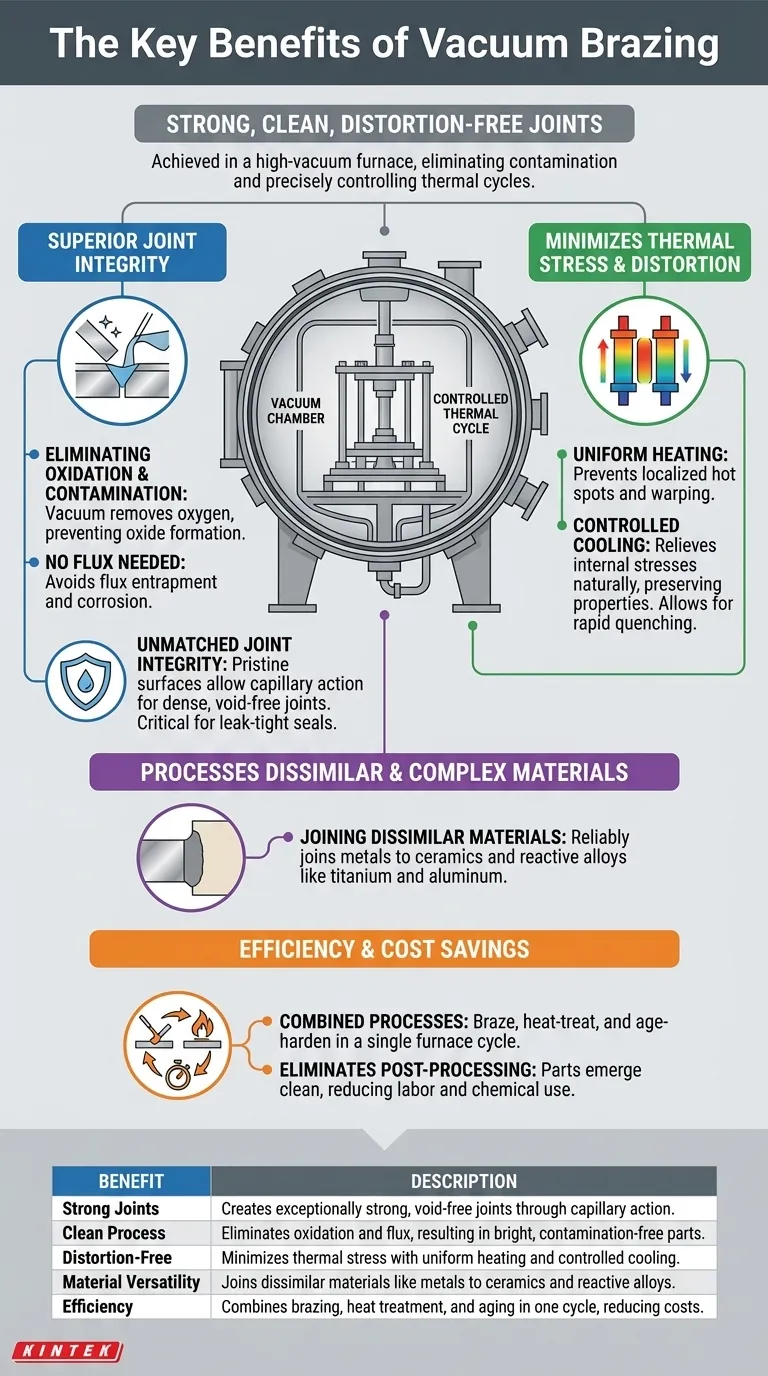

The key benefits of vacuum brazing are the creation of exceptionally strong, clean, and distortion-free joints, especially in complex assemblies or with sensitive materials. This is achieved by performing the joining process inside a high-vacuum furnace, which eliminates atmospheric contamination and allows for precise control over the entire thermal cycle, from heating to cooling.

The core challenge in advanced manufacturing is joining materials without compromising their integrity. Vacuum brazing solves this by creating an ideal, contamination-free environment that minimizes thermal stress, enabling strong, void-free joints between even dissimilar and complex materials.

The Foundation: How Vacuum Brazing Achieves Superior Joints

Vacuum brazing is a process where a filler material melts and joins components together inside a vacuum. The principles behind this environment are what deliver its primary benefits.

Eliminating Oxidation and Contamination

In a normal atmosphere, heating metals creates oxides on the surface that interfere with the joining process. A vacuum removes virtually all oxygen and other reactive gases.

This prevents oxides from forming, resulting in a perfectly clean surface for the filler metal to adhere to. The final parts emerge from the furnace bright and clean, often requiring no post-process cleaning.

Because the vacuum environment is inherently clean, there is no need for flux—a chemical agent used in other brazing methods. This completely eliminates the risk of flux entrapment, a common cause of corrosion and joint failure over time.

Ensuring Unmatched Joint Integrity

The pristine surfaces allow the molten filler metal to flow freely and wet the parent materials completely through capillary action.

This action pulls the filler into the tightest gaps, creating a dense, void-free joint. This is critical for applications requiring leak-tight seals, such as in fuel, hydraulic, or high-pressure systems.

Processing Dissimilar and Complex Materials

The highly controlled nature of vacuum brazing makes it one of the few methods capable of reliably joining materials with different properties.

This includes joining metals to ceramics or joining reactive alloys like titanium and aluminum, which are extremely difficult to join with conventional welding due to their rapid oxidation.

Minimizing Thermal Stress and Distortion

A major failure point in material joining is the stress and warping caused by heat. Vacuum brazing is specifically designed to manage this thermal impact.

The Importance of Uniform Heating

Inside a vacuum furnace, the entire assembly is heated slowly and uniformly. This prevents the localized hot spots common in welding that cause components to warp or distort.

Every part of the assembly reaches the brazing temperature at the same time, ensuring consistent filler flow and minimizing internal stress.

The Role of Controlled Cooling

After brazing, the assembly is cooled at a slow, precisely controlled rate. This allows internal stresses to relieve naturally, preserving the material's original metallurgical properties and dimensional stability.

While slow cooling is standard, some furnaces also have options for rapid quenching with inert gas. This allows for specific metallurgical outcomes, like hardening, to be achieved in the same cycle.

Understanding the Trade-offs and Requirements

The benefits of vacuum brazing are significant, but they are not achieved without meeting specific requirements. Understanding these is key to a successful outcome.

The Critical Need for Cleanliness

Vacuum brazing is not a forgiving process. Any surface contaminants like oils, grease, or dirt on the parts will vaporize in the vacuum (outgas) and contaminate the entire furnace load, leading to poor or failed joints.

Parts must be meticulously cleaned and handled in a clean environment before being loaded into the furnace.

The Investment in Equipment and Expertise

Vacuum furnaces are complex, high-cost capital equipment. They require skilled operators to manage the process variables, from vacuum levels to precise temperature profiles.

This makes the process less suited for low-cost, one-off repairs and better suited for high-value, production-level work where quality and repeatability are paramount.

Gaining Efficiency Beyond the Braze

The true economic advantage of vacuum brazing often comes from process consolidation.

Combining Processes in a Single Cycle

A single furnace run can be used to perform multiple thermal processes at once. It is common to braze, heat-treat, and age-harden components in one continuous cycle.

This consolidation saves immense amounts of time, energy, and material handling costs compared to performing each step in a separate piece of equipment.

Eliminating Post-Processing

As parts emerge from the furnace clean and free of oxidation, the need for post-braze cleaning to remove flux or scale is eliminated. This reduces labor costs, decreases turnaround time, and avoids the use of hazardous cleaning chemicals.

Making the Right Choice for Your Application

Use these guidelines to determine if vacuum brazing is the correct approach for your project.

- If your primary focus is joining dissimilar or sensitive materials (e.g., aerospace alloys, ceramics to metal): Vacuum brazing is the premier choice due to its non-contaminating and thermally controlled environment.

- If your primary focus is maximum joint strength and leak-tight integrity (e.g., fuel systems, medical devices): The flux-free, void-free nature of vacuum brazed joints provides unmatched reliability.

- If your primary focus is high-volume production of complex assemblies: The ability to process entire batches and combine heat treatment cycles in one run offers significant cost and time savings.

- If your primary focus is rapid, low-cost joining of simple, non-critical parts: Conventional methods like welding or atmospheric torch brazing are likely more cost-effective.

By understanding these principles, you can confidently leverage vacuum brazing to solve complex joining challenges that other methods simply cannot address.

Summary Table:

| Benefit | Description |

|---|---|

| Strong Joints | Creates exceptionally strong, void-free joints through capillary action. |

| Clean Process | Eliminates oxidation and flux, resulting in bright, contamination-free parts. |

| Distortion-Free | Minimizes thermal stress with uniform heating and controlled cooling. |

| Material Versatility | Joins dissimilar materials like metals to ceramics and reactive alloys. |

| Efficiency | Combines brazing, heat treatment, and aging in one cycle, reducing costs. |

Ready to enhance your manufacturing with vacuum brazing? KINTEK specializes in advanced high-temperature furnace solutions, including Vacuum & Atmosphere Furnaces, tailored for industries like aerospace and medical devices. Leveraging our exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique needs for strong, clean joints. Contact us today to discuss how our expertise can benefit your projects!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- What is the purpose of a 1400°C heat treatment for porous tungsten? Essential Steps for Structural Reinforcement

- What is the role of vacuum pumps in a vacuum heat treatment furnace? Unlock Superior Metallurgy with Controlled Environments

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity