In essence, a multi-chamber continuous vacuum furnace excels by transforming a sequential, stop-and-go process into a highly efficient, continuous production line. Unlike single or two-chamber batch furnaces that must heat up and cool down for every load, a multi-chamber system keeps its heating zone at a constant temperature. Workpieces move through separate, optimized chambers for each stage, dramatically increasing throughput while slashing energy consumption.

The core advantage is the separation of functions. By dedicating chambers to specific tasks like heating and cooling, multi-chamber continuous furnaces eliminate the massive time and energy waste inherent in the thermal cycling of batch systems, making them ideal for modern mass production.

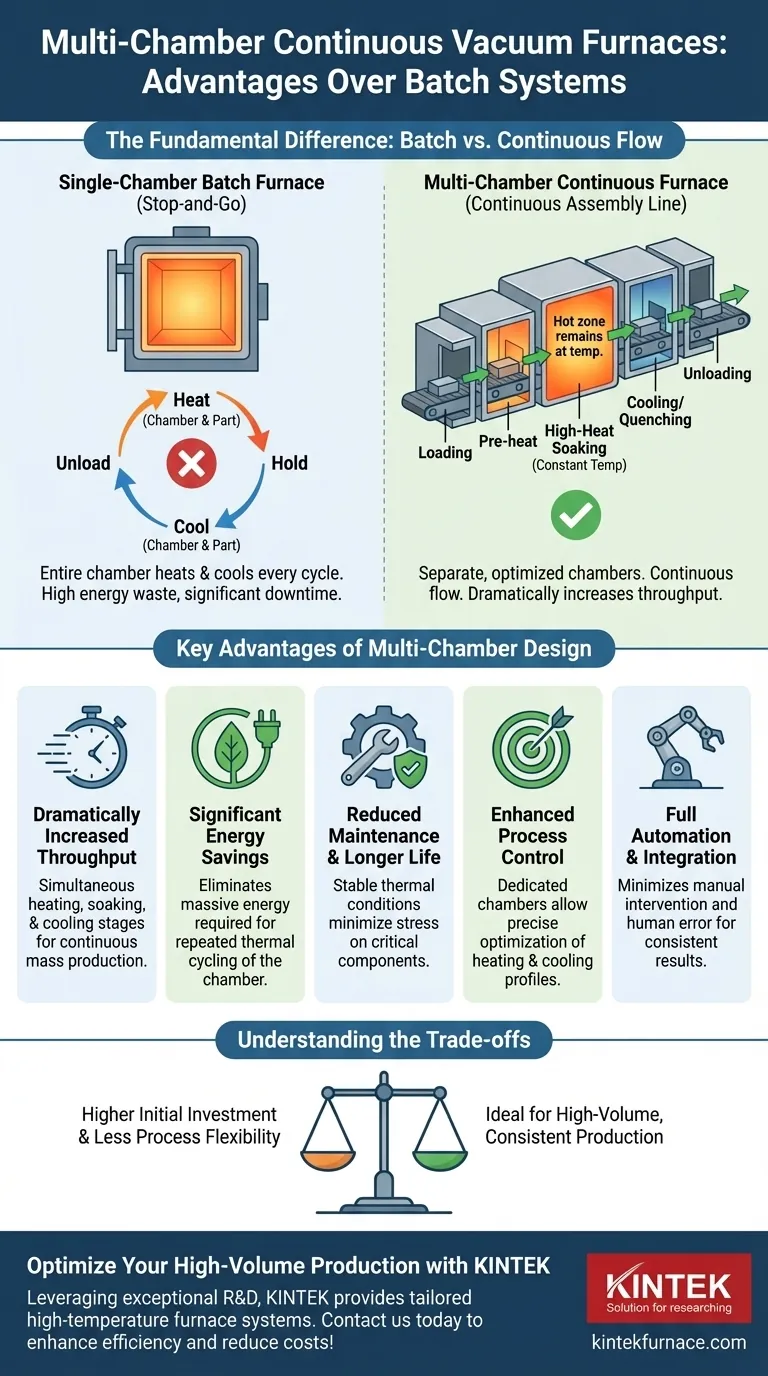

The Fundamental Difference: Continuous Flow vs. Batch Processing

To understand the advantages, it's crucial to first visualize the operational difference between the two furnace architectures. They represent two fundamentally different philosophies of production.

How Single-Chamber Batch Furnaces Work

A traditional single-chamber batch furnace performs every step of the heat treatment process sequentially in one vessel. The cycle involves loading the material, pumping out the air to create a vacuum, heating the chamber to the target temperature, holding it, cooling the chamber back down, and finally unloading the finished parts.

The entire thermal mass of the furnace—including its walls, insulation, and fixtures—must be heated and cooled for every single batch. This creates significant downtime and energy inefficiency.

The Multi-Chamber Continuous Advantage

A multi-chamber continuous furnace operates like an assembly line. It consists of a series of connected chambers, each optimized for a specific part of the process (e.g., loading, pre-heating, high-heat soaking, cooling/quenching, and unloading).

Workpieces are automatically transferred from one chamber to the next. Critically, the high-heat chamber remains at its operating temperature continuously, while the cooling chamber remains cold. Only the workpiece itself moves between thermal zones.

Key Advantages of the Multi-Chamber Design

This continuous-flow architecture delivers several compounding benefits that are essential for high-volume industrial applications.

Dramatically Increased Throughput

Because heating, soaking, and cooling occur simultaneously in different chambers, the furnace's output is not limited by the time it takes to complete one full cycle. A new batch can enter the heating chamber as soon as the previous one moves to the cooling chamber, enabling a continuous flow of production ideal for mass manufacturing.

Significant Energy Savings

This is arguably the most impactful advantage. By keeping the hot zone perpetually at temperature, you eliminate the enormous energy required to repeatedly heat the entire furnace chamber from a cold state. The stored heat is retained and utilized efficiently, leading to a much lower energy cost per part produced.

Reduced Maintenance and Longer Equipment Life

The constant heating and cooling of a batch furnace (thermal cycling) induces significant stress on components like heating elements, insulation, and the chamber itself. A continuous furnace's stable hot zone minimizes this stress, resulting in lower maintenance costs and a longer operational lifespan for critical components.

Enhanced Process Control and Consistency

With dedicated chambers for each stage, the heating and cooling profiles can be more precisely controlled and optimized. This separation prevents the compromises inherent in using a single chamber for both functions, leading to superior metallurgical repeatability and product quality batch after batch.

Full Automation and Integration

These systems are designed as fully automatic, electromechanical integrated production lines. This reduces the need for manual intervention, minimizes the potential for human error, and ensures a highly consistent and reliable manufacturing process.

Understanding the Trade-offs

Despite their clear advantages for mass production, multi-chamber furnaces are not the universal solution. Objectivity requires acknowledging their limitations.

Higher Initial Investment

Continuous vacuum furnaces are complex, large-scale systems. Their initial purchase price, installation cost, and facility requirements are significantly higher than those of a standard batch furnace. The economic justification depends entirely on achieving high-volume production.

Less Process Flexibility

These furnaces are typically optimized for a specific, consistent production run. They are not well-suited for job shops or R&D environments that require frequent changes in process parameters, cycle times, or part geometries for small, varied batches.

Making the Right Choice for Your Application

The decision between a batch and a continuous furnace is a strategic one based on your specific production goals and economic realities.

- If your primary focus is high-volume, continuous production of a consistent part: A multi-chamber continuous furnace is the superior choice for achieving the lowest per-unit cost, highest throughput, and best energy efficiency.

- If your primary focus is process flexibility for varied, low-volume batches or R&D: A single-chamber batch furnace offers a far more practical and cost-effective solution due to its lower initial cost and operational adaptability.

- If your primary focus is balancing increased throughput with some flexibility: A two-chamber batch furnace, which separates heating and quenching, can serve as an effective middle ground, improving on the cycle time of a single-chamber model without the full cost and scale of a continuous system.

Ultimately, choosing the right furnace technology requires a clear understanding of your long-term production volume, process requirements, and capital investment strategy.

Summary Table:

| Advantage | Description |

|---|---|

| Increased Throughput | Continuous flow allows simultaneous heating, soaking, and cooling, ideal for mass production. |

| Energy Savings | Eliminates thermal cycling, reducing energy costs by maintaining a constant hot zone temperature. |

| Reduced Maintenance | Stable thermal conditions minimize stress on components, lowering maintenance and extending lifespan. |

| Enhanced Process Control | Dedicated chambers enable precise temperature and cooling control for consistent, high-quality results. |

| Full Automation | Integrated systems reduce manual intervention, ensuring reliability and minimizing errors. |

Ready to optimize your high-volume production with advanced furnace solutions? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with tailored high-temperature furnace systems. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental and production needs. Contact us today to discuss how our multi-chamber continuous vacuum furnaces can enhance your efficiency and reduce costs!

Visual Guide

Related Products

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What preparations are needed before starting a multi zone tube furnace? Ensure Safety and Accuracy in Your Lab

- What advantages do multi zone tube furnaces offer for chemical reaction studies? Achieve Precise Thermal Control

- How are multi zone tube furnaces used in ceramics, metallurgy and glass research? Unlock Precise Thermal Control for Advanced Materials

- How are multi zone tube furnaces applied in biomedical research? Unlock Advanced Biomaterial Engineering

- What safety precautions should be followed when operating a multi zone tube furnace? Ensure Safe and Efficient Lab Operations