The primary benefits of a vacuum furnace are superior material quality, exceptional process control, and significant operational versatility. By heating materials in a controlled, low-pressure environment, these furnaces prevent common issues like oxidation and contamination, resulting in cleaner, stronger, and more reliable components for critical industries.

A vacuum furnace's core advantage isn't just its ability to generate heat, but its power to control the environment. By removing reactive gases like oxygen, it enables metallurgical processes and achieves material properties that are impossible to attain in a standard atmosphere furnace.

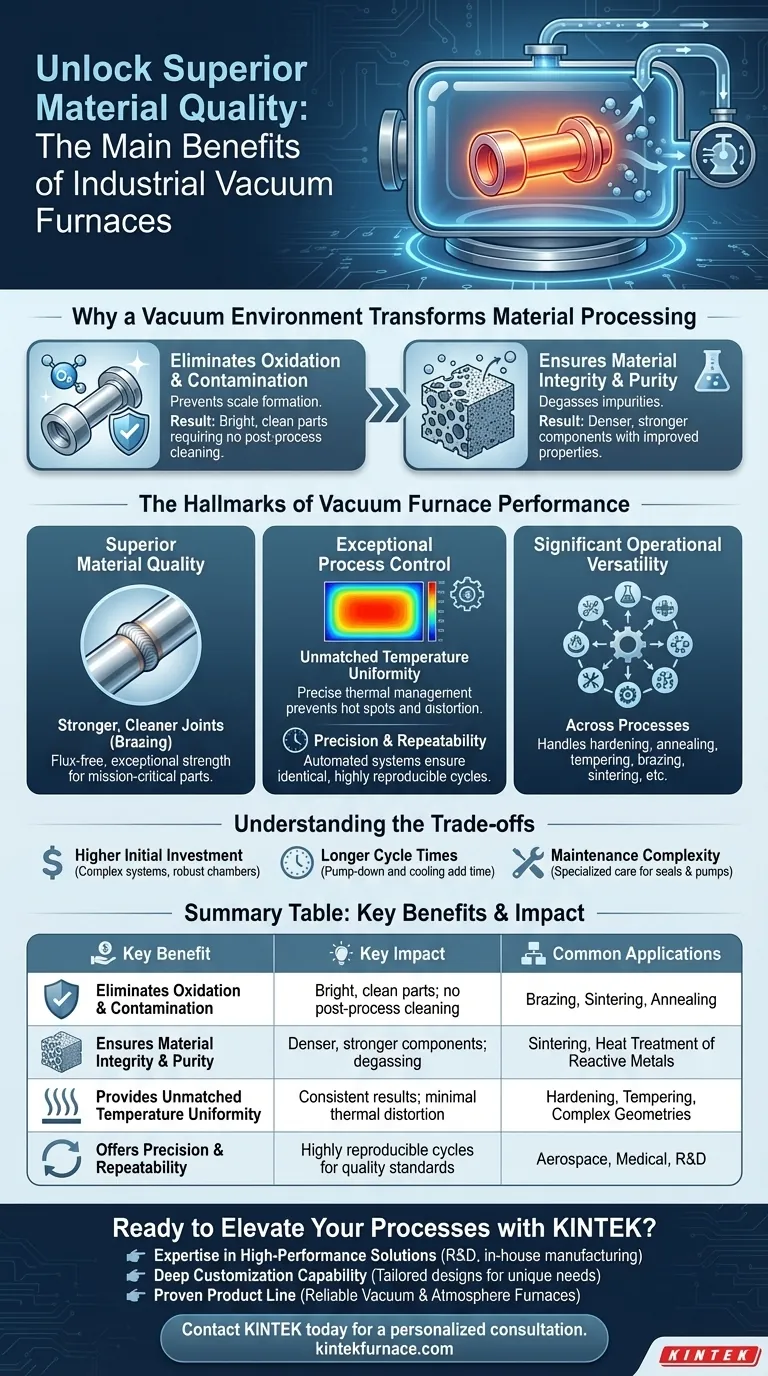

Why a Vacuum Environment Transforms Material Processing

The defining feature of a vacuum furnace is the removal of air and other gases from the heating chamber. This fundamental difference is the source of its most significant benefits.

Eliminating Oxidation and Contamination

At high temperatures, most metals react aggressively with oxygen in the air. This reaction, known as oxidation, creates a layer of scale on the material's surface, which can compromise its properties and finish.

A vacuum furnace removes virtually all oxygen, completely preventing this degradation. The resulting parts are bright, clean, and require no subsequent cleaning to remove scale.

Ensuring Material Integrity and Purity

The vacuum environment also helps to degas the material itself. As the material is heated under vacuum, trapped gases and other volatile impurities are drawn out, leading to a purer, denser final product with improved mechanical properties.

This is especially critical for processes like sintering, where it helps create high-density components with minimal porosity.

Creating Stronger, Cleaner Joints

For joining processes like brazing, the vacuum environment is a game-changer. It eliminates the need for flux, a chemical agent used in traditional brazing to prevent oxidation.

Flux can leave behind corrosive residues that weaken the joint over time. Vacuum brazing produces exceptionally strong, clean, and flux-free joints, essential for mission-critical parts in aerospace and medical applications.

The Hallmarks of Vacuum Furnace Performance

Beyond the environmental control, the design of a vacuum furnace delivers unparalleled consistency and flexibility in production environments.

Unmatched Temperature Uniformity

Heating in a vacuum occurs primarily through radiation. This allows for extremely uniform heat distribution throughout the workload, preventing hot spots and minimizing thermal distortion in complex parts.

This precise thermal management ensures that every part in a batch receives the exact same heat treatment.

Precision and Repeatability

Modern vacuum furnaces are managed by sophisticated computer control systems. These systems allow operators to program, execute, and record every step of the thermal cycle with incredible accuracy.

This high level of automation guarantees that every cycle is identical, delivering highly reproducible results that are essential for meeting stringent industry certifications and quality standards.

Versatility Across Processes

A single vacuum furnace can be programmed to handle an extensive range of metallurgical processes. This versatility makes it a highly valuable asset in any modern manufacturing facility.

Common applications include hardening, annealing, tempering, brazing, sintering, and case hardening processes like nitriding and carburizing.

Understanding the Trade-offs

While the benefits are significant, a vacuum furnace is not the universal solution for every heating application. It's crucial to understand the associated costs and complexities.

Higher Initial Investment

Vacuum furnaces are complex systems involving robust chambers, advanced control systems, and high-performance vacuum pumps. This complexity results in a significantly higher initial capital cost compared to conventional atmosphere furnaces.

Longer Cycle Times

The process of pumping the chamber down to the required vacuum level adds time to the beginning of each cycle. Likewise, the process of backfilling the chamber with an inert gas for cooling can also extend the overall process duration.

Maintenance Complexity

The integrity of the vacuum system is paramount. Seals, pumps, and instrumentation require specialized and diligent maintenance to prevent leaks and ensure the system operates at peak efficiency. This adds a layer of operational overhead not present with simpler furnaces.

Making the Right Choice for Your Application

Selecting the right thermal processing technology depends entirely on the requirements of your final product and your operational priorities.

- If your primary focus is maximum material purity and performance: A vacuum furnace is essential for processing reactive metals or any application where oxidation cannot be tolerated.

- If your primary focus is joining complex geometries or dissimilar materials: Vacuum brazing provides superior joint strength, cleanliness, and dimensional stability compared to other methods.

- If your primary focus is high-volume, lower-spec heat treatment: The higher cost and longer cycle times of a vacuum furnace may be unnecessary; a traditional atmosphere furnace is often more cost-effective.

Ultimately, choosing a vacuum furnace is an investment in unparalleled control over the material's environment, enabling you to produce components of the highest possible quality.

Summary Table:

| Key Benefit | Key Impact | Common Applications |

|---|---|---|

| Eliminates Oxidation & Contamination | Bright, clean parts; no post-process cleaning | Brazing, Sintering, Annealing |

| Ensures Material Integrity & Purity | Denser, stronger components; degassing | Sintering, Heat Treatment of Reactive Metals |

| Provides Unmatched Temperature Uniformity | Consistent results; minimal thermal distortion | Hardening, Tempering, Complex Geometries |

| Offers Precision & Repeatability | Highly reproducible cycles for quality standards | Aerospace, Medical, R&D |

Ready to Elevate Your Industrial Processes with Unmatched Purity and Control?

At KINTEK, we understand that achieving superior material quality is non-negotiable for your most critical applications. Our advanced vacuum furnace solutions are engineered to deliver the precise, contamination-free environment your processes demand.

Why Partner with KINTEK?

- Expertise in High-Performance Solutions: Leveraging our exceptional R&D and in-house manufacturing, we provide advanced vacuum and atmosphere furnace solutions tailored for diverse laboratory and industrial needs.

- Deep Customization Capability: We go beyond standard offerings. Whether you require a specific temperature profile, unique chamber size, or specialized gas quenching system, our team works with you to design a furnace that precisely meets your unique experimental and production requirements.

- Proven Product Line: Our range includes robust Vacuum & Atmosphere Furnaces, CVD/PECVD Systems, and more, all built for reliability and precision.

Invest in the quality and integrity of your components. Let our experts help you determine the ideal vacuum furnace solution for your specific application.

Contact KINTEL today for a personalized consultation and discover how our vacuum furnace technology can transform your results.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing