At its core, a vacuum furnace operates by heating materials within a sealed chamber from which air and other gases have been removed. This fundamental process relies on several key features: powerful vacuum pumps to create the low-pressure environment, specialized heating elements to reach extreme temperatures, and precise control systems to manage the entire cycle. The primary goal is to prevent atmospheric contamination, such as oxidation, during heat treatment.

The defining operational feature of a vacuum furnace is its ability to create a chemically inert environment. By removing oxygen and other reactive gases, it allows for heat treatment processes that preserve material purity and surface integrity, which is impossible in a standard atmosphere furnace.

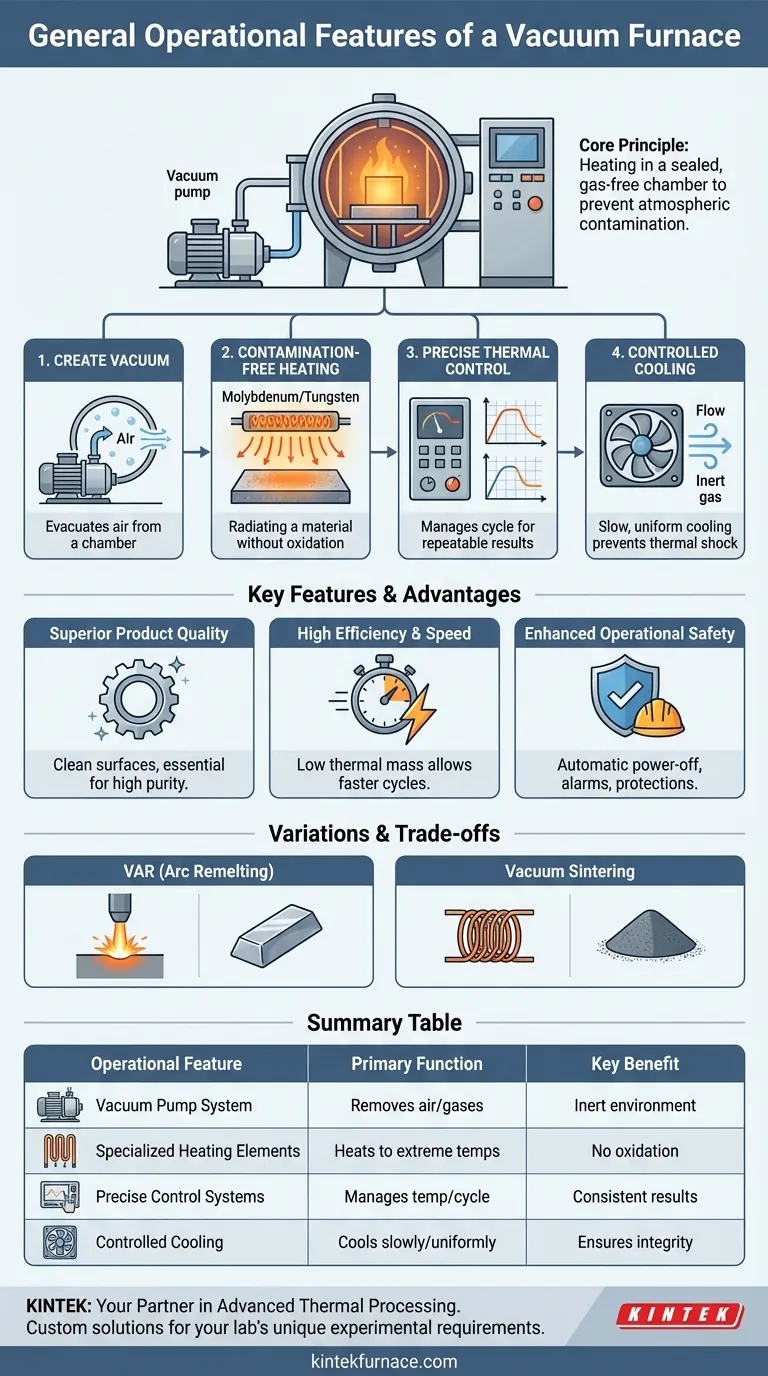

The Core Operational Principle: A Controlled Environment

The entire function of a vacuum furnace revolves around manipulating the atmosphere to achieve specific material properties. This is a deliberate, multi-stage process.

Step 1: Creating the Vacuum

The process begins by loading materials into a sealed chamber. A system of vacuum pumps is then activated to evacuate the chamber, removing air, moisture, and other volatile gases. This step is critical for creating the controlled, low-pressure (vacuum) environment.

Step 2: Heating Without Contamination

Once the desired vacuum level is reached, internal heating elements are energized. These elements, often made from high-temperature materials like molybdenum or tungsten, heat the workload. Because this occurs in a near-vacuum, it prevents common high-temperature reactions like oxidation and decarburization.

Step 3: Precise Thermal Control

Integrated control systems manage the entire thermal cycle with high precision. This includes the rate of temperature rise, the duration the material is held at a specific temperature (the "soak"), and the cooling rate. This ensures repeatable and stable results for every batch.

Step 4: Controlled Cooling

After the heating phase is complete, the furnace begins a controlled cooling cycle. The material's temperature is lowered slowly and uniformly within the vacuum or with the help of an inert backfill gas. This prevents thermal shock and allows for safe removal once the process is finished.

Key Features and Resulting Advantages

The operational design of a vacuum furnace directly translates into significant advantages for high-performance applications.

Superior Product Quality

By eliminating reactive gases, the furnace ensures the final product has a clean, unaltered surface. This is essential for applications in aerospace, medical, and electronics where material purity is paramount.

High Efficiency and Speed

Compared to traditional heavy refractory furnaces, modern vacuum furnaces often have chambers with low thermal mass. This allows for much faster heating and cooling cycles, reducing overall process time and saving significant energy.

Enhanced Operational Safety

These systems are designed with user safety as a priority. Standard features include an automatic power-off function when the furnace door is opened, over-temperature alarms, and electrical protections for overvoltage or leakage.

Understanding the Variations and Trade-offs

The term "vacuum furnace" describes a category of equipment, not a single device. The specific heating method can vary based on the application, which introduces different operational characteristics.

Not a One-Size-Fits-All Technology

Different processes require different types of vacuum furnaces. The fundamental principle of creating a vacuum remains the same, but the method of heat application changes.

Example: Vacuum Arc Remelting (VAR)

A VAR furnace uses a high-energy electric arc to melt a consumable electrode in a vacuum. This process is used to produce extremely high-purity metal ingots by removing dissolved gases and impurities.

Example: Vacuum Sintering Furnace

This type of furnace often uses induction heating to generate high temperatures. It is ideal for sintering powdered metals or ceramics into a solid mass, where preventing oxidation is crucial for achieving the desired density and strength.

The Primary Limitation

The main trade-off is complexity and cost. Operating and maintaining a vacuum system is more demanding than using a simple air furnace. This technology is therefore reserved for processes where the benefits of an inert environment justify the investment.

Making the Right Choice for Your Goal

The operational features of a vacuum furnace are best understood in the context of your specific material processing objective.

- If your primary focus is material purity and preventing surface oxidation: The vacuum system's ability to remove reactive gases is its most critical feature.

- If your primary focus is process repeatability and precision: The integrated, stable control systems for managing temperature and pressure are essential for achieving consistent results.

- If your primary focus is high-temperature processing of reactive metals: The combination of a vacuum environment and specialized heating elements (like tungsten) is the key enabler.

Ultimately, understanding these core operational principles empowers you to leverage the unique capabilities of vacuum heat treatment for superior material outcomes.

Summary Table:

| Operational Feature | Primary Function | Key Benefit |

|---|---|---|

| Vacuum Pump System | Removes air and gases from the chamber | Creates a contamination-free, inert environment |

| Specialized Heating Elements | Heats materials to extreme temperatures | Enables high-temperature processing without oxidation |

| Precise Control Systems | Manages temperature, pressure, and cycle times | Ensures repeatable, stable, and consistent results |

| Controlled Cooling | Cools materials slowly and uniformly | Prevents thermal shock and ensures material integrity |

Ready to Leverage a Vacuum Furnace for Your Lab?

Understanding the operational features is the first step. The next is implementing the right solution to achieve your specific material processing goals, whether it's unparalleled purity for aerospace components, precise repeatability for R&D, or high-temperature sintering for advanced ceramics.

KINTEK is your partner in advanced thermal processing. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Vacuum & Atmosphere Furnaces, CVD/PECVD Systems, Muffle, Tube, and Rotary Furnaces, is complemented by our strong deep customization capability to precisely meet your unique experimental requirements.

Let us help you achieve superior material outcomes. Contact our experts today to discuss how a KINTEK vacuum furnace can be tailored to enhance your lab's efficiency, safety, and results.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion