Properly handling a vacuum furnace door and its samples is a critical discipline centered on precision, safety, and protecting the equipment's integrity. Always open and close the furnace door gently to preserve its vital vacuum seal. When retrieving a sample, use crucible clamps with deliberate, careful movements to avoid damaging the furnace's delicate internal components. After a cycle, turn off the power, open the door slightly for a preliminary cooldown, and then carefully remove the sample to prevent personal injury and thermal shock to the material.

The procedures for operating a vacuum furnace are fundamentally about preserving the integrity of a highly controlled environment. Every action, from closing the door to removing a sample, is designed to protect the vacuum seal, the delicate internal components, and the operator from extreme temperatures.

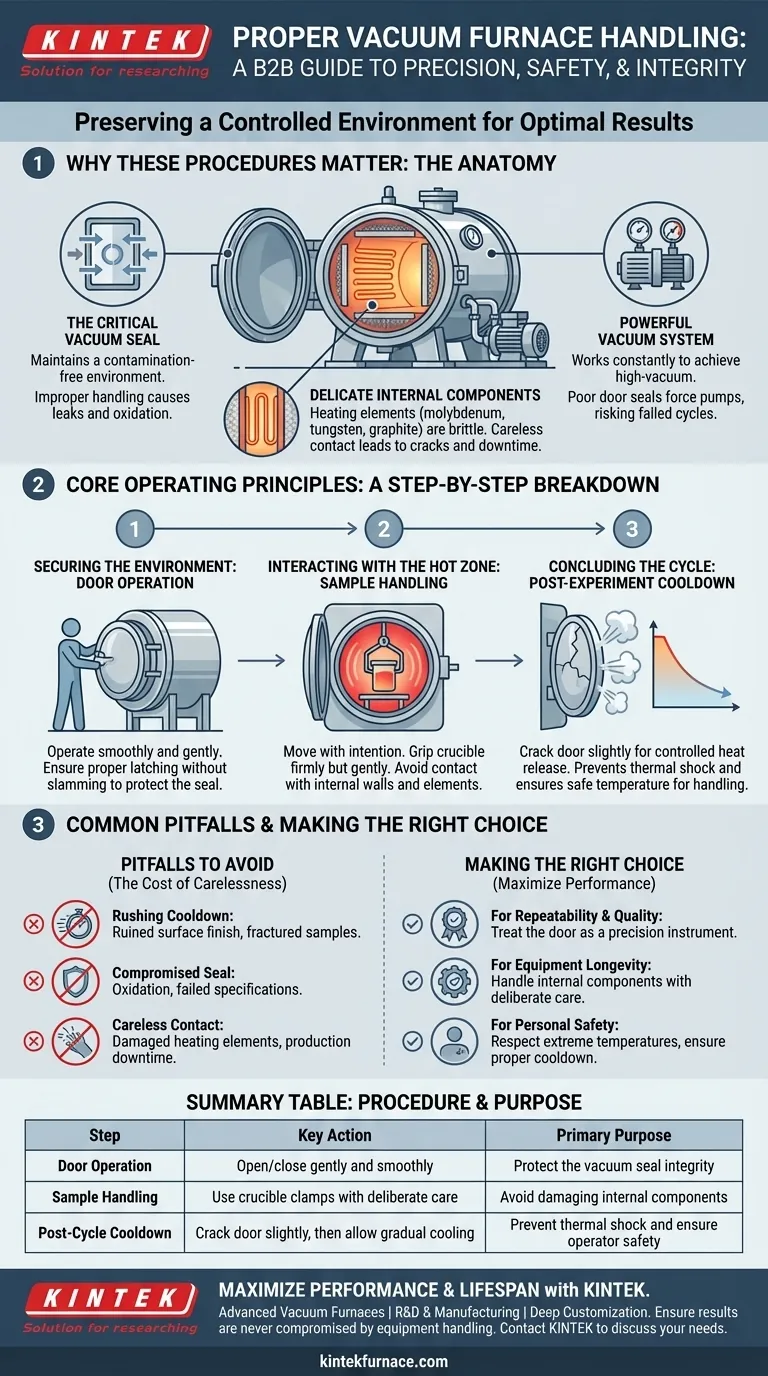

Why These Procedures Matter: The Anatomy of a Vacuum Furnace

To understand the handling procedures, you must first understand the equipment itself. A vacuum furnace is not a simple oven; it is a sophisticated system where each component has a critical function.

The Crucial Role of the Vacuum Chamber

A vacuum furnace's primary purpose is to create a sealed, contamination-free environment. The vacuum system actively removes oxygen, nitrogen, and other gases that cause oxidation and unwanted reactions at high temperatures.

The furnace door is the most important part of this seal. Improper or rough handling can misalign or damage the seals, creating leaks that compromise the entire process.

The Delicate Nature of Internal Components

Inside the chamber are fragile, high-performance components. The heating elements, often made of brittle materials like molybdenum, tungsten, or graphite, generate the extreme heat.

These elements, along with the furnace's insulation, can be easily damaged by careless contact. Using crucible clamps forcefully can lead to cracks or fractures, resulting in expensive repairs and significant equipment downtime.

The Power of the Vacuum System

The vacuum system, composed of various pumps, works constantly to achieve and maintain a high-vacuum state. A poor door seal forces these pumps to work harder or, in many cases, prevents them from reaching the required vacuum level, leading to a failed heating cycle.

Core Operating Principles: A Step-by-Step Breakdown

Each step in the process is designed to mitigate a specific risk associated with high-temperature, high-vacuum operations.

Securing the Environment: Door Operation

Always operate the furnace door smoothly and gently. When closing, ensure it is properly latched without slamming it. This single action protects the seal that is fundamental to the entire heat-treating process.

Interacting with the Hot Zone: Sample Handling

When placing or removing a sample, move with intention and care. Grip the crucible firmly but gently with the clamps. Avoid any contact with the furnace walls, heating elements, or temperature sensors inside the chamber.

Concluding the Cycle: Post-Experiment Cooldown

After the heating cycle is complete and the power is off, the final steps are critical for both safety and material quality. Cracking the door open slightly allows for a controlled release of heat.

This gradual cooldown prevents thermal shock—a rapid temperature change that can crack or warp both your sample and the furnace's internal components. Most importantly, it allows the extremely hot material to cool enough to be handled safely, preventing severe burns.

Common Pitfalls to Avoid

Understanding what can go wrong reinforces the importance of correct procedure.

The Risk of Rushing the Cooldown

Impatience is the enemy of good results. Opening the door fully while the sample is still at a very high temperature introduces a rush of cool, oxygen-rich air, which can ruin the sample's surface finish or even cause it to fracture.

The Consequence of a Compromised Seal

A small, unnoticed leak from rough door handling can ruin an entire batch of materials. The slow ingress of oxygen can cause oxidation, leading to parts that do not meet their required metallurgical specifications.

The Hidden Cost of Carelessness

Accidentally striking a heating element with a clamp may seem minor, but it can create a stress point that leads to failure during the next heat cycle. This results not only in the cost of the part but also in lost production time.

Making the Right Choice for Your Goal

Your approach should be dictated by your primary objective for using the furnace.

- If your primary focus is process repeatability and quality: Treat the furnace door as a precision instrument; its seal is the guardian against the contamination that ruins results.

- If your primary focus is equipment longevity and cost-effectiveness: Handle all internal components with deliberate care; gentle movements prevent costly damage to brittle heating elements and insulation.

- If your primary focus is personal safety: Always respect the extreme temperatures involved; allow for a proper and sufficient cooldown period before handling any materials removed from the furnace.

Ultimately, treating a vacuum furnace with methodical discipline ensures the integrity of your materials, the longevity of the equipment, and the safety of everyone in the lab.

Summary Table:

| Step | Key Action | Primary Purpose |

|---|---|---|

| Door Operation | Open/close gently and smoothly | Protect the vacuum seal integrity |

| Sample Handling | Use crucible clamps with deliberate care | Avoid damaging internal components (heating elements) |

| Post-Cycle Cooldown | Crack door slightly, then allow gradual cooling | Prevent thermal shock and ensure operator safety |

Maximize the performance and lifespan of your vacuum furnace. The procedures outlined above are essential for any lab, but the right equipment is the foundation. KINTEK's advanced vacuum furnaces are engineered for precision and durability. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with robust solutions. Our product line, including Vacuum & Atmosphere Furnaces and CVD/PECVD Systems, is complemented by strong deep customization capabilities to meet your unique experimental requirements precisely.

Ensure your results are never compromised by equipment handling or quality. Contact our experts today to discuss a vacuum furnace solution built for your specific needs.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing

- How does vacuum heat treatment improve mechanical properties of metals? Enhance Strength and Durability

- Why use a vacuum furnace? Achieve Unparalleled Material Purity and Process Control

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today