The fundamental reason to use a vacuum furnace is to achieve unparalleled material purity and process control during heat treatment. By removing the atmosphere, you eliminate the variable and destructive influence of reactive gases like oxygen, ensuring the final product meets the most demanding metallurgical specifications without contamination or surface defects.

A vacuum furnace is not simply a heater; it is a highly controlled environment. Its primary value lies in creating a chemically inert space, allowing for heat treatment processes that are physically impossible to achieve in an open-air or even a standard atmosphere furnace.

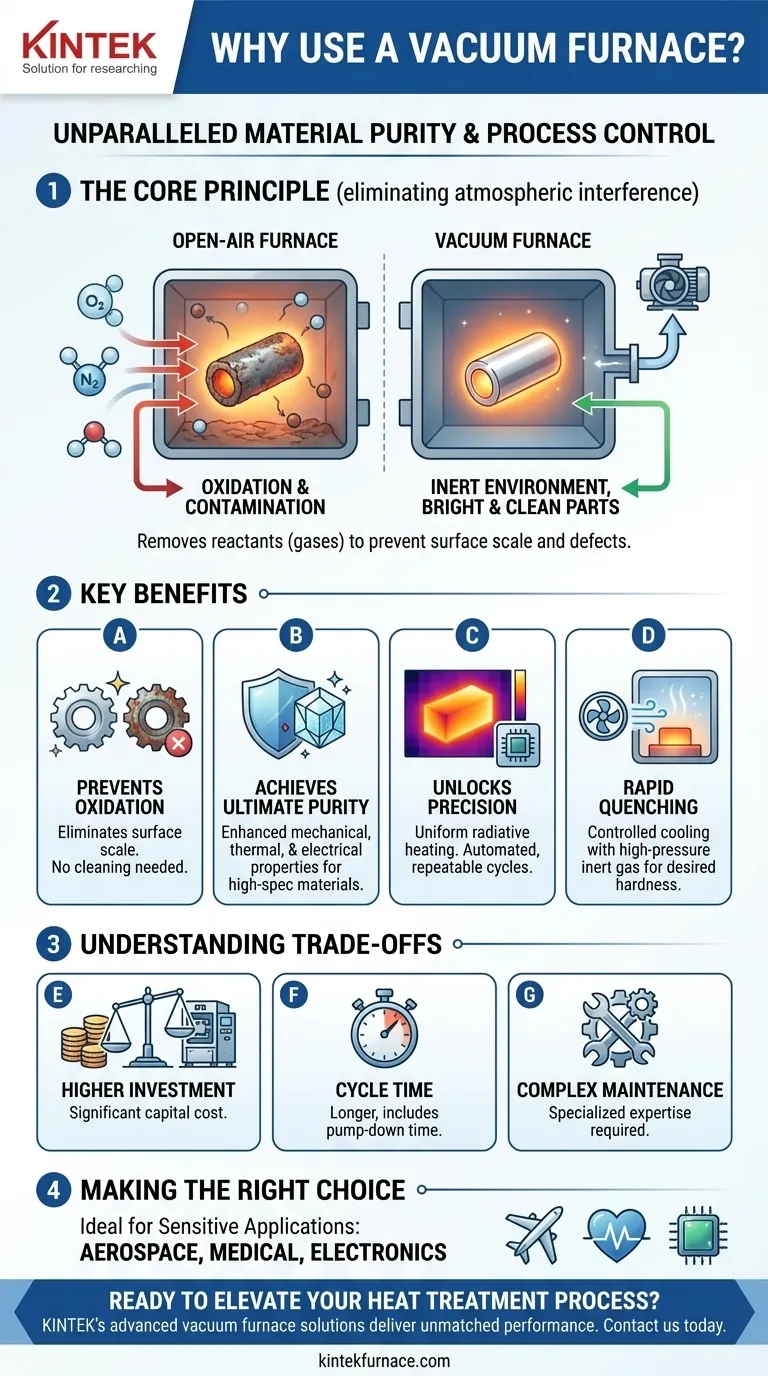

The Core Principle: Eliminating Atmospheric Interference

When a material is heated, its reactivity increases dramatically. A vacuum furnace directly addresses this challenge by removing the reactants—the gases in the air—that would otherwise compromise the material's integrity.

Preventing Oxidation and Contamination

At high temperatures, most metals will readily react with oxygen in the air, forming a layer of oxide scale on the surface. This process not only damages the surface finish but can also alter the dimensions of a precision part.

A vacuum furnace pumps the air out of the chamber to extremely low pressures. This eliminates oxygen and other reactive gases, preventing oxidation, nitridation, and other unwanted chemical reactions from occurring on the material's surface.

The result is a bright, clean part that requires no subsequent cleaning or machining to remove scale, saving both time and material.

Achieving Ultimate Material Purity

For advanced applications in industries like aerospace, medical, and electronics, even trace amounts of gaseous contamination can degrade material properties. A vacuum environment is the cleanest possible setting for heat treatment.

This ensures that the material's final chemical composition is precisely what was intended. The process yields parts with enhanced mechanical, thermal, and electrical properties because the underlying metallurgy has not been compromised.

Unlocking Precision and Repeatability

Beyond purity, a vacuum furnace provides an exceptional level of control over the entire thermal cycle. This precision is critical for developing and manufacturing high-performance materials.

Uniform and Accurate Temperature Control

In a vacuum, heat is transferred primarily through radiation, not convection. This allows for highly uniform heating, ensuring that all parts of the workload, regardless of their position in the furnace, reach the same temperature at the same time.

Modern vacuum furnaces use sophisticated control systems and multiple temperature sensors. This enables precise temperature management, often within just a few degrees, which is crucial for hitting the exact metallurgical targets of sensitive alloys.

The Power of Computer-Controlled Cycles

Because the environment is completely contained and managed, the entire heat treatment process can be automated. Technicians can program precise heating rates, soak times, pressure levels, and cooling rates.

This computer control ensures unmatched metallurgical repeatability. Every batch processed with the same recipe will have identical properties, which is a non-negotiable requirement for high-specification components.

Rapid Cooling (Quenching) Capabilities

After heating, many processes require rapid cooling, or quenching, to lock in desirable material properties like hardness.

Vacuum furnaces achieve this by backfilling the hot chamber with a high-pressure, inert gas like nitrogen or argon. Powerful fans then circulate this gas, removing heat from the parts at a controlled and very rapid rate, a process often cleaner and more controllable than traditional oil or water quenching.

Understanding the Trade-offs

While powerful, a vacuum furnace is not the universal solution for all heat treatment. Understanding its limitations is key to making an informed decision.

Higher Initial Investment

Vacuum furnaces, with their complex chambers, seals, and high-performance pumping systems, represent a significantly higher capital investment compared to conventional atmosphere furnaces.

Cycle Time Considerations

The total cycle time in a vacuum furnace can be longer than in an atmosphere furnace. The time required to pump the chamber down to the required vacuum level before heating begins must be factored into production planning.

Maintenance Complexity

Maintaining a vacuum furnace is more demanding. It requires specialized knowledge to service the vacuum pumps, check for leaks, and calibrate the advanced instrumentation to ensure the system performs as designed.

Making the Right Choice for Your Application

Selecting the right furnace technology depends entirely on your material, your budget, and the quality requirements of your final product.

- If your primary focus is material integrity and surface finish: For applications like medical implants, aerospace turbine blades, or sensitive electronic components, the clean, non-reactive environment of a vacuum furnace is essential.

- If your primary focus is process repeatability for high-spec parts: For heat treating tool steels, superalloys, or other materials with narrow processing windows, the precision control of a vacuum furnace is its key advantage.

- If your primary focus is high-volume, low-cost processing: For simple processes like annealing common steel parts where surface oxidation is acceptable or easily removed, a less expensive atmosphere furnace is often the more economical choice.

Ultimately, choosing a vacuum furnace is a strategic decision to prioritize quality, purity, and control above all else.

Summary Table:

| Key Advantage | Benefit |

|---|---|

| Prevents Oxidation | Eliminates surface scale and contamination for bright, clean parts. |

| Ensures Material Purity | Creates a chemically inert environment for high-specification metallurgy. |

| Provides Precise Control | Enables uniform heating, repeatable cycles, and controlled quenching. |

| Ideal for Sensitive Applications | Essential for aerospace, medical, and electronics industries. |

Ready to Elevate Your Heat Treatment Process?

For industries where material purity and precision are non-negotiable—such as aerospace, medical, and electronics—KINTEK's advanced vacuum furnace solutions deliver unmatched performance. Leveraging our exceptional R&D and in-house manufacturing, we offer a diverse range of high-temperature furnaces, including Vacuum & Atmosphere Furnaces and CVD/PECVD Systems, complemented by deep customization capabilities to meet your unique experimental needs.

Contact us today to discuss how our expertise can enhance your lab's efficiency and product quality. Get in touch now!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today