At its core, vacuum brazing prevents oxidation by physically removing the oxygen required for oxides to form. By performing the heating process inside a vacuum furnace, the atmosphere is evacuated, creating an environment where the base metals and filler alloy can be heated to brazing temperatures without reacting with oxygen, ensuring a chemically pure and exceptionally strong joint.

The fundamental advantage of vacuum brazing is not merely managing contamination, but eliminating its root cause. By removing the reactive atmosphere, it creates pristine metal surfaces that are impossible to achieve with traditional flux-based methods.

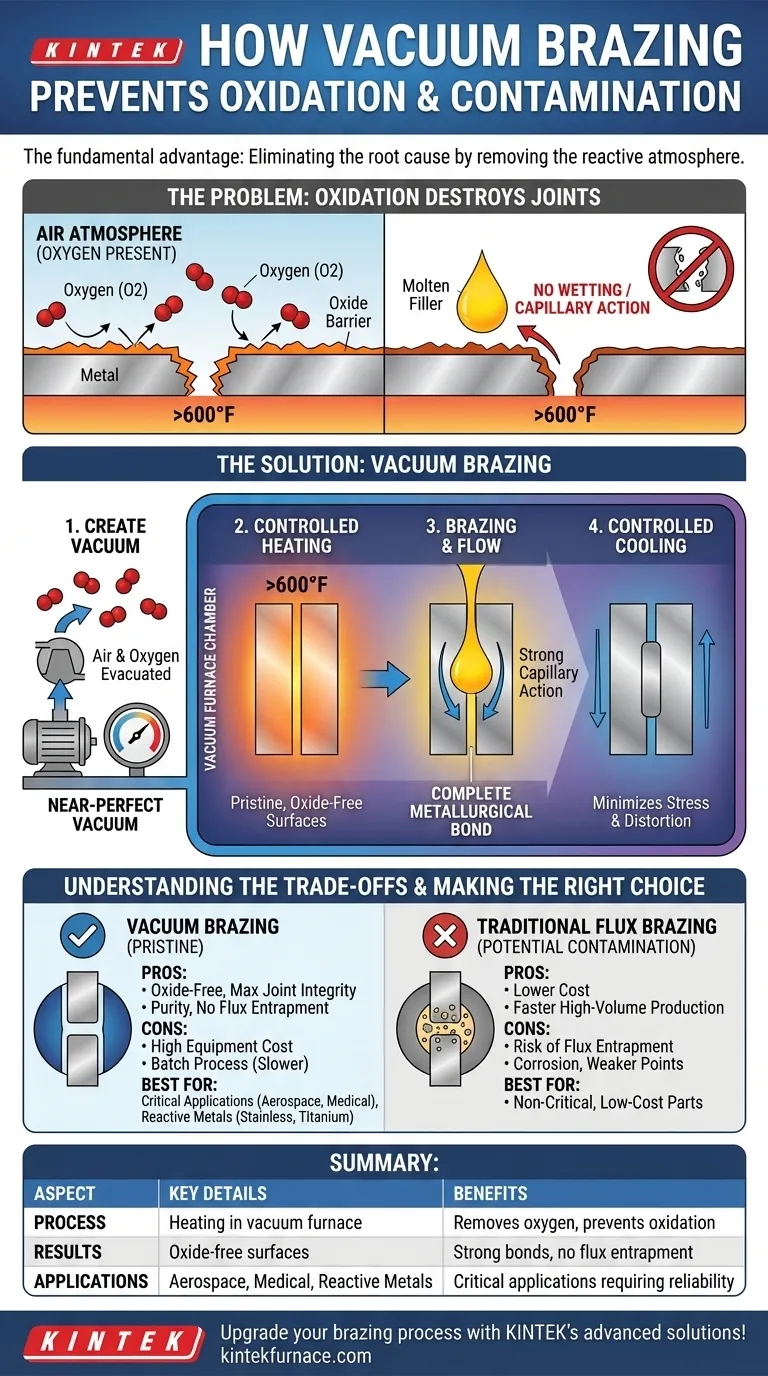

The Problem: Why Oxidation Destroys a Braze Joint

To understand the value of a vacuum, you must first understand the enemy: oxidation. At elevated temperatures, most metals rapidly react with oxygen in the air to form a thin, brittle layer of metal oxide on their surface.

Oxides as a Barrier

This oxide layer acts as a physical barrier. It prevents the molten brazing filler metal from making direct contact with the pure base metal beneath it.

Proper brazing relies on a phenomenon called capillary action, where the molten filler is drawn into the tight-fitting gap between the parts. If an oxide layer is present, it disrupts the "wetting" action, stopping the filler from flowing and bonding correctly.

The Result of Oxidation

The result is a weak, unreliable joint with voids and gaps. The filler metal may ball up on the surface or fail to penetrate the joint, leading to immediate part failure under stress.

How Vacuum Brazing Eliminates the Threat

Vacuum brazing tackles this problem by changing the environment entirely. The process relies on a specialized, sealed chamber called a vacuum furnace.

Step 1: Creating the Vacuum

Before any heating begins, a powerful system of vacuum pumps removes the air—and critically, the oxygen—from the furnace chamber. This process, known as "pumping down," reduces the internal pressure to a near-perfect vacuum.

Step 2: Controlled Heating

With the oxygen gone, the parts can be heated to the required brazing temperature, often exceeding 600°F (315°C). Because there is no reactive atmosphere, the metal surfaces remain clean and active, even at extreme temperatures.

Step 3: Brazing and Filler Flow

Once at temperature, the pre-placed brazing filler metal melts. On the pristine, oxide-free surfaces, it flows smoothly and is drawn deeply into the joint by capillary action, creating a complete, void-free metallurgical bond.

Step 4: Controlled Cooling

After brazing, the parts are cooled slowly and uniformly within the vacuum or an inert gas environment. This controlled cooling minimizes thermal stress and prevents distortion, a common issue with localized heating methods like torch brazing.

Understanding the Trade-offs

While highly effective, vacuum brazing is not the solution for every application. Understanding its limitations is key to making an informed decision.

Equipment and Cost

Vacuum furnaces are complex, expensive pieces of capital equipment. The initial investment and ongoing maintenance costs are significantly higher than those for simpler methods like torch or induction brazing.

Process Time and Batching

Vacuum brazing is a batch process. Loading the furnace, pumping it down, running the thermal cycle, and cooling can take several hours. This makes it less suitable for high-volume, continuous production lines where speed is the primary driver.

The Alternative: Chemical Flux

The traditional alternative to a vacuum is using a chemical flux. Flux is a paste or powder that melts and chemically cleans the surfaces, dissolving oxides. However, flux can become trapped in the joint, causing corrosion or creating a weak point. Vacuum brazing eliminates the risk of flux entrapment entirely.

Making the Right Choice for Your Goal

Selecting the right brazing method depends entirely on the requirements of your application.

- If your primary focus is maximum joint integrity and purity: Vacuum brazing is the definitive choice for critical applications in aerospace, medical, and semiconductor industries where joint failure is not an option.

- If your primary focus is joining reactive metals: For materials like stainless steel, titanium, or aluminum that form tenacious oxides, vacuum brazing is often the only reliable method to achieve a clean, strong bond.

- If your primary focus is low-cost, high-volume production of non-critical parts: Traditional methods like torch brazing with flux or controlled atmosphere furnace brazing may offer a more cost-effective and faster solution.

By removing the atmospheric variables, vacuum brazing provides unparalleled control and delivers the cleanest, strongest, and most reliable brazed joints possible.

Summary Table:

| Aspect | Key Details |

|---|---|

| Process | Heating in vacuum furnace to remove oxygen, preventing oxidation |

| Benefits | Oxide-free surfaces, strong metallurgical bonds, no flux entrapment |

| Applications | Aerospace, medical devices, semiconductor, reactive metals like stainless steel and titanium |

| Limitations | High equipment cost, batch processing, longer cycle times |

Upgrade your brazing process with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace options like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capability ensures precise fit for your unique experimental needs, delivering clean, reliable joints for critical applications. Contact us today to discuss how we can enhance your lab's efficiency and results!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What role does a rapid vacuum chamber play in measuring the evaporation rates? Achieve Precision Timing at t=0

- What environmental benefits do continuous vacuum furnaces provide? Achieve Zero Emissions and High Efficiency

- How is a two-stage heating process implemented in plasma nitriding equipment? Master Surface Consistency

- What is the function of a vacuum drying oven in rice husk carbonization? Ensure Chemical Stability & Material Integrity

- What are the main heat treatment processes used in high-temperature vacuum furnaces? Achieve Superior Material Properties

- What is the primary function of a vacuum annealing furnace? Optimize Zircaloy-4 Alloy Pretreatment and Purity

- What are some common industrial uses of vacuum furnaces? Enhance Material Quality and Performance

- What role do the exhaust branch pipes at the top of a vacuum chamber play? Optimize Your Pressure Control Today