The choice of material for a vacuum furnace hot zone is determined by a critical balance of temperature resistance, chemical inertness, and cost. The most common materials are refractory metals like molybdenum and tungsten, various forms of graphite, and ceramic fibers. These are often used in specialized configurations, such as all-metal zones for high-purity applications or graphite zones for cost-effective, ultra-high temperature work.

The selection of a hot zone material is not merely a question of what can withstand the heat. It is a strategic decision that directly impacts process purity, operational cost, and the chemical integrity of the material being processed. The central trade-off is between the cleanliness of metallic zones and the cost-effective, high-temperature performance of graphite.

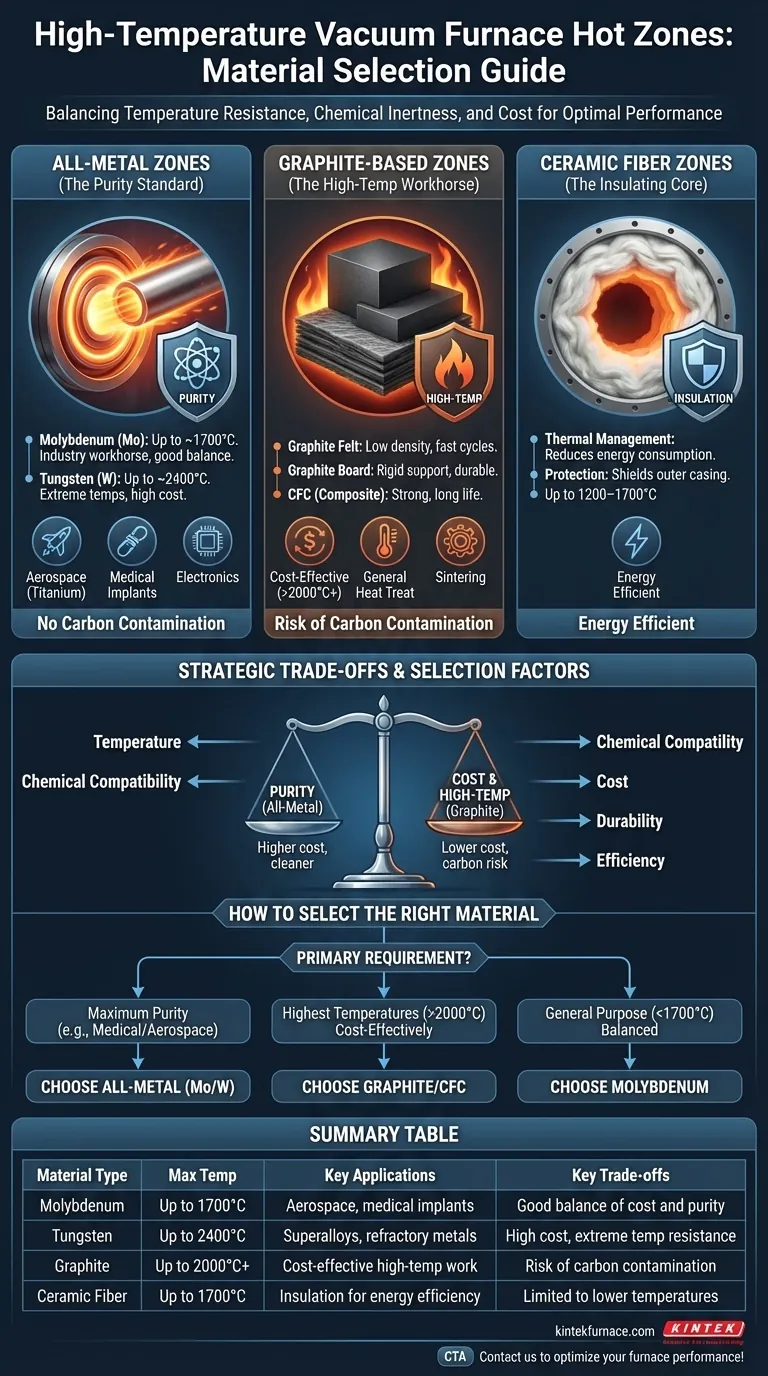

The Anatomy of a Hot Zone: Key Material Categories

The "hot zone" is the heart of the furnace, containing the heating elements and the insulation shields that reflect thermal energy back onto the workpiece. The materials used for these components define the furnace's capabilities.

All-Metal Hot Zones: The Purity Standard

All-metal hot zones are constructed entirely from refractory metals. They are the definitive choice for applications where contamination, especially from carbon, is unacceptable.

Molybdenum (Mo) is the industry workhorse for a vast range of high-temperature applications up to approximately 1700°C. It offers excellent durability, cleanliness, and a good balance of cost and performance.

Tungsten (W) is used for the most extreme temperature requirements, capable of operating at up to 2400°C. Its high cost reserves it for processes involving advanced superalloys or refractory metal sintering where no other material can perform.

These zones are essential for processing reactive metals like titanium for aerospace, biocompatible materials for medical implants, and high-purity components for the electronics industry.

Graphite-Based Hot Zones: The High-Temp Workhorse

Graphite hot zones are valued for their ability to reach very high temperatures at a lower cost than all-tungsten designs. They are typically constructed from one of three main forms.

Graphite Felt is a soft, low-density material used for insulation. Its low thermal mass allows for rapid heating and cooling cycles, improving furnace throughput.

Graphite Board is a rigid, structural material used for support and as a more durable insulating layer.

Carbon-Carbon Composite (CFC) is an extremely strong and durable material used for heating elements, racks, and fixtures. It resists warping and provides a long service life in demanding cycles.

Ceramic Fiber Hot Zones: The Insulating Core

Ceramic fiber is a lightweight, highly efficient insulation material. While not typically used for heating elements, it forms the insulating chamber in many furnaces designed for lower to moderate temperatures (1200–1700°C).

Its primary role is thermal management. By effectively containing heat, ceramic fiber insulation reduces energy consumption and protects the furnace's outer, water-cooled steel casing.

Matching the Hot Zone to the Application

The ideal hot zone material is dictated by the process parameters and the nature of the workload. The two most important factors are temperature and chemical compatibility.

Why Temperature Dictates the First Choice

The maximum required operating temperature is the first filter for material selection.

- Up to 1700°C: Molybdenum and ceramic fiber are excellent, proven choices.

- 1700°C to 2000°C+: Graphite becomes the most cost-effective solution.

- Up to 2400°C: Tungsten is required for its unparalleled heat resistance.

The Critical Role of Chemical Compatibility

A vacuum environment prevents oxidation, but at high temperatures, materials can still react with each other. This is the central conflict between metal and graphite zones.

A graphite hot zone can introduce carbon into the furnace atmosphere. This is unacceptable when processing materials that are sensitive to carbon, as it can form unwanted carbides and compromise the material's properties. Titanium alloys are a prime example.

An all-metal hot zone provides a much cleaner environment with minimal outgassing. This is non-negotiable for high-purity applications in the medical, aerospace, and semiconductor fields.

Understanding the Trade-offs

Choosing a hot zone material involves balancing competing priorities. There is no single "best" material, only the most appropriate one for a specific goal.

Purity vs. Cost

This is the most significant trade-off. All-metal hot zones, particularly those made of tungsten or tantalum, are significantly more expensive to build and maintain than graphite hot zones. Graphite offers a high-temperature capability at a fraction of the cost, but with the inherent risk of carbon interaction.

Durability and Lifespan

Both material types are subject to wear. Metallic elements can become brittle over many thermal cycles through a process called recrystallization. Graphite elements and insulation can also become brittle and are more susceptible to mechanical shock or accidental breakage during loading and unloading.

Energy Efficiency and Cycle Times

The thermal mass of the hot zone impacts performance. Lightweight graphite felt has a low thermal mass, enabling faster heat-up and cool-down rates. This can dramatically increase furnace productivity. Heavier metallic radiation shields have a higher thermal mass, resulting in slower cycles but often providing superior temperature uniformity.

How to Select the Right Hot Zone Material

Use your primary process requirement as the guide to your decision.

- If your primary focus is maximum purity for sensitive materials (e.g., medical, aerospace): Choose an all-metal hot zone, typically molybdenum or tantalum, to avoid any risk of carbon contamination.

- If your primary focus is reaching the highest possible temperatures (above 2000°C) cost-effectively: A graphite or carbon-composite hot zone is the industry standard, provided your material is not reactive with carbon.

- If your primary focus is general-purpose processing below 1700°C: A molybdenum hot zone offers a balanced blend of performance, cleanliness, and durability that suits a wide range of applications.

Understanding these core material properties empowers you to select a furnace design that ensures both the integrity of your process and the quality of your final product.

Summary Table:

| Material Type | Max Temperature | Key Applications | Key Trade-offs |

|---|---|---|---|

| Molybdenum | Up to 1700°C | Aerospace, medical implants | Good balance of cost and purity |

| Tungsten | Up to 2400°C | Superalloys, refractory metals | High cost, extreme temperature resistance |

| Graphite | Up to 2000°C+ | Cost-effective high-temperature work | Risk of carbon contamination |

| Ceramic Fiber | Up to 1700°C | Insulation for energy efficiency | Limited to lower temperatures |

Ready to enhance your lab's high-temperature processes? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, with strong deep customization capabilities to meet your unique experimental requirements. Whether you're in aerospace, medical, or electronics, we'll help you select the perfect hot zone material for purity, temperature, and cost efficiency. Contact us today to discuss how we can optimize your furnace performance!

Visual Guide

Related Products

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What are the benefits of integrating multiple heating zones in a tube furnace? Unlock Precise Thermal Control

- What steps are involved in the installation of a multi zone tube furnace? Ensure Precision and Safety for Your Lab

- How do multi zone tube furnaces improve laboratory efficiency? Boost Throughput with Parallel Processing

- How are multi zone tube furnaces applied in biomedical research? Unlock Advanced Biomaterial Engineering

- What advantages do multi zone tube furnaces offer for chemical reaction studies? Achieve Precise Thermal Control