In a vacuum furnace, heat transfer occurs primarily through thermal radiation, as the near-total absence of air molecules makes conventional heating methods like convection and conduction through a gas impossible. Heat is delivered from the heating elements to the material via electromagnetic waves, while conduction still occurs through any solid parts, such as the workpiece itself and the fixtures holding it.

While thermal radiation is the only way heat can cross the empty space in a vacuum, achieving precise and uniform temperature control depends entirely on understanding the system as a whole—including how heat conducts through solid components and how the furnace is designed to generate and remove that heat.

The Dominant Role of Thermal Radiation

The defining characteristic of a vacuum is the absence of a medium. This fundamentally changes the physics of heat transfer compared to a standard atmospheric furnace.

Why Convection and Conduction Fail

Convection requires the movement of fluid molecules (like gas or liquid) to carry heat. Conduction through a gas requires molecules to collide and transfer kinetic energy.

With most of these molecules removed, these two primary heat transfer mechanisms are effectively eliminated in the empty space of the vacuum chamber.

Heat as Electromagnetic Waves

Thermal radiation is the transfer of heat via electromagnetic waves, primarily in the infrared spectrum. Unlike conduction and convection, it requires no medium to travel.

The heating elements in the furnace grow hot and radiate energy in all directions. This energy travels through the vacuum until it is absorbed by the material being processed, causing its temperature to rise.

The Impact on Uniformity

Because radiation travels in straight lines, achieving uniform heating is a significant design challenge. The placement and design of heating elements and insulation are critical to ensure all surfaces of the workpiece receive adequate energy.

Beyond Radiation: A Systems View of Heat Flow

While radiation dominates heat transfer through the vacuum, it's not the only mechanism at play within the furnace system.

Conduction Through Solid Components

Heat still moves very effectively via conduction through all solid materials. This includes the heating elements themselves, the furnace walls or retort, any fixtures holding the workpiece, and within the workpiece itself.

Understanding this conductive path is crucial for predicting how a part will heat up internally.

Method 1: Resistive Heating

Most vacuum furnaces use resistive heating elements made of graphite or refractory metals. An electric current passes through these elements, causing them to heat up and radiate energy.

The heat radiates from the elements to the workpiece, making this a form of indirect heating.

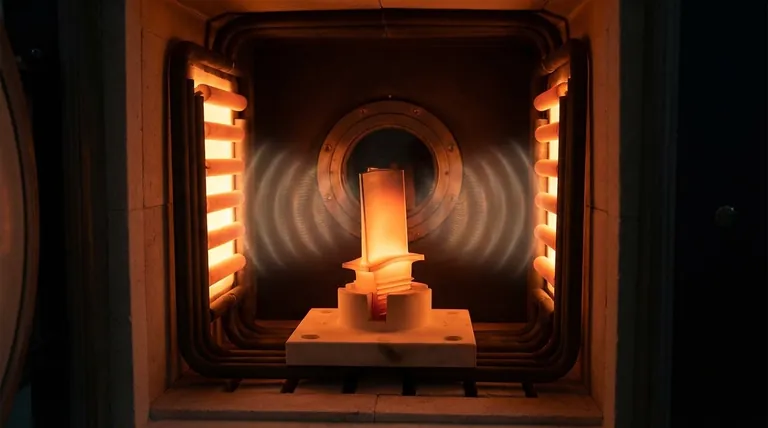

Method 2: Induction Heating

Some furnaces use induction to heat the material directly. An alternating current in a copper coil creates a powerful electromagnetic field.

This field induces eddy currents within the conductive workpiece itself, generating heat internally. This bypasses the need for radiation to transfer energy from an external source to the part's surface.

Understanding the Trade-offs and Challenges

Heating in a vacuum prevents oxidation and contamination, but it introduces unique thermal management challenges that must be addressed.

The Problem of "Line-of-Sight"

Radiation requires a direct, unobstructed path from the source to the target. Any part of the workpiece that is "shadowed" by another part or a fixture will not heat effectively.

This can create significant temperature gradients and non-uniform results, especially with complex geometries. Proper part placement is critical.

Controlling the Thermal Field

To combat shadowing and ensure uniform heating, furnace design is paramount. Multiple heating zones, reflective shielding, and carefully engineered insulation are used to create a homogenous "thermal field" where energy is coming from all directions.

The Importance of Cooling Cycles

Removing heat is just as important as adding it. Cooling a part inside a vacuum is very slow, as radiation is once again the only mechanism available to dissipate energy into the cold furnace walls.

For faster cycle times, an inert gas like nitrogen or argon is backfilled into the chamber. This reintroduces convection as a powerful and rapid cooling mechanism, a process often called gas quenching.

Making the Right Choice for Your Process

Your specific goal determines which aspects of vacuum heat transfer are most important to control.

- If your primary focus is process purity: The key benefit of the vacuum environment is the prevention of oxidation and unwanted chemical reactions with atmospheric gases.

- If your primary focus is uniform heating: Pay close attention to furnace design, element placement, and potential "line-of-sight" shadowing issues with your workpiece.

- If your primary focus is rapid cycle times: A furnace equipped with a high-pressure gas quenching system for forced convective cooling is essential.

By understanding these principles, you can leverage the unique environment of a vacuum furnace to achieve exceptional control and material quality.

Summary Table:

| Mechanism | Role in Vacuum Furnace | Key Characteristics |

|---|---|---|

| Thermal Radiation | Primary heat transfer method | Requires no medium, travels as electromagnetic waves, can cause shadowing |

| Conduction | Occurs through solid components | Transfers heat within workpiece, fixtures, and elements |

| Convection | Absent in vacuum, used in cooling | Reintroduced via gas quenching for rapid heat removal |

Unlock the full potential of your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable equipment like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, enhancing process purity, uniformity, and efficiency. Don't let heat transfer challenges hold you back—contact us today to discuss how our tailored solutions can elevate your research and production outcomes!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today