At its core, a high vacuum furnace is designed for materials that cannot tolerate atmospheric contamination at high temperatures. This includes reactive metals like titanium and molybdenum, advanced ceramics such as silicon carbide, various metal powders, and high-purity optical materials like zinc sulfide.

The choice to use a high vacuum furnace is less about a specific list of compatible materials and more about the desired outcome. These furnaces are essential for processing materials that are highly reactive, require extreme purity, or must be densified in an oxygen-free environment to achieve superior structural or optical properties.

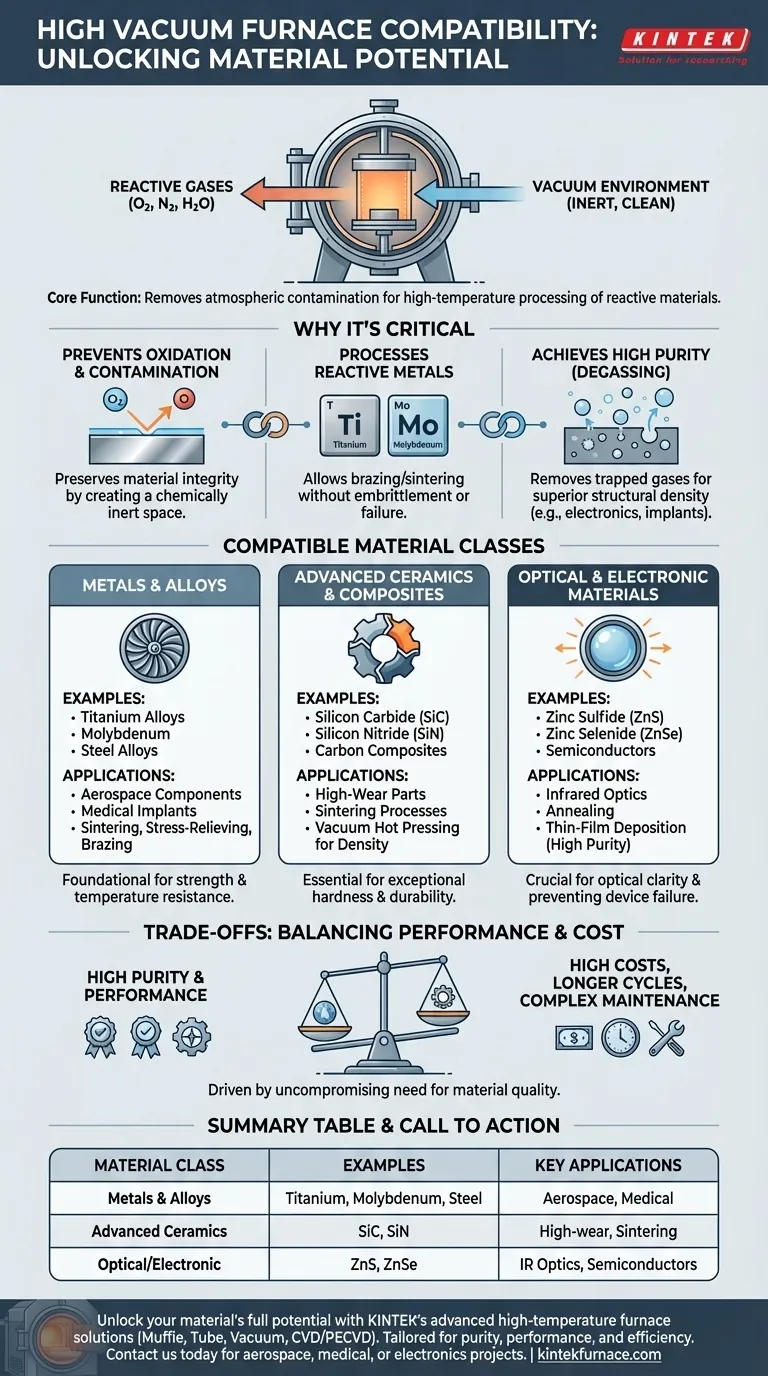

Why a Vacuum Environment is Critical

The defining feature of a high vacuum furnace is what it removes: reactive gases. This controlled environment is the key to unlocking the potential of many advanced materials.

Preventing Oxidation and Contamination

At elevated temperatures, most materials will readily react with oxygen, nitrogen, and water vapor present in the air. This forms oxides and nitrides that can compromise a material's strength, conductivity, or other critical properties.

A high vacuum environment removes these reactive gases, creating a chemically inert space. This ensures the material's integrity is preserved throughout the thermal process.

Processing Highly Reactive Metals

Metals like titanium (Ti) and molybdenum (Mo) are prime candidates for vacuum processing. They are prized for their strength and temperature resistance, but they are also extremely reactive.

Exposing these metals to heat in an open atmosphere would lead to embrittlement and failure. The vacuum furnace allows them to be brazed, sintered, or heat-treated without this destructive oxidation.

Achieving High Purity and Degassing

Many materials contain trapped or dissolved gases from their initial manufacturing. When heated, these gases can escape, creating voids and defects in the final product.

The vacuum actively pulls these trapped gases out of the material—a process called degassing. This is critical for applications in electronics and medical implants, where material purity and structural density are paramount.

A Breakdown of Compatible Material Classes

High vacuum furnaces are versatile tools used across several industries. The compatibility extends to any material that benefits from a clean, high-temperature processing environment.

Metals and Alloys

Commonly processed metals include titanium alloys, steel alloys, and refractory metals. These are foundational materials in the aerospace industry, where the furnace is used for processes like sintering, stress-relieving, and brazing turbine blades or structural components.

Advanced Ceramics and Composites

Materials like silicon carbide (SiC), silicon nitride (SiN), and various carbon composites are processed in vacuum furnaces.

Processes like vacuum hot pressing and sintering are used to fuse powdered ceramics into dense, solid parts with exceptional hardness and durability, suitable for high-wear applications.

Optical and Electronic Materials

High vacuum is essential for producing infrared optical components from materials like zinc sulfide (ZnS) and zinc selenide (ZnSe). The purity achieved in a vacuum ensures maximum optical clarity.

Similarly, the furnace is used for annealing and thin-film deposition in the manufacturing of semiconductors and other electronic components where any contamination could cause device failure.

Understanding the Trade-offs

While powerful, high vacuum furnaces come with specific challenges that make them unsuitable for every application.

High Equipment and Operational Costs

High vacuum systems are significantly more expensive to purchase and operate than their atmospheric counterparts. The pumps, chambers, and control systems required are complex and costly.

Longer Process Cycles

Achieving a high vacuum is not instantaneous. The pump-down time—the period it takes to evacuate the chamber to the target pressure—can add significant time to each processing cycle, reducing overall throughput.

Complex Maintenance Requirements

Maintaining the integrity of a high vacuum system is demanding. Seals, gaskets, and pumps require regular inspection and service to prevent leaks that would compromise the entire process.

Making the Right Choice for Your Application

Selecting the right thermal processing technology depends entirely on your material and your end goal.

- If your primary focus is aerospace or medical components: High vacuum is essential for processing reactive alloys like titanium to ensure their required strength and biocompatibility.

- If your primary focus is producing advanced ceramics: A vacuum furnace is the key to sintering processes that achieve maximum density and superior mechanical properties.

- If your primary focus is high-purity optical or electronic materials: The inert, clean environment of a high vacuum furnace is non-negotiable for preventing performance-killing contamination.

Ultimately, the decision to use a high vacuum furnace is driven by an uncompromising need for material purity and performance.

Summary Table:

| Material Class | Examples | Key Applications |

|---|---|---|

| Metals and Alloys | Titanium, Molybdenum, Steel Alloys | Aerospace components, medical implants |

| Advanced Ceramics | Silicon Carbide, Silicon Nitride | High-wear parts, sintering processes |

| Optical and Electronic Materials | Zinc Sulfide, Zinc Selenide | Infrared optics, semiconductors |

Unlock the full potential of your materials with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored solutions like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements for enhanced purity, performance, and efficiency. Contact us today to discuss how we can support your aerospace, medical, or electronics projects!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance