At its core, vacuum sintering is a high-temperature manufacturing process that fuses powdered materials into a solid, dense object without melting them. This is achieved by heating the material within a vacuum chamber, which removes air and other gases. The absence of atmosphere is critical, as it prevents oxidation and contamination, resulting in a final part with superior strength, purity, and consistency.

The fundamental advantage of vacuum sintering is not just the heat, but the vacuum itself. By removing reactive gases like oxygen, the process enables the bonding of high-performance and reactive materials that would be impossible to process effectively in a normal atmosphere.

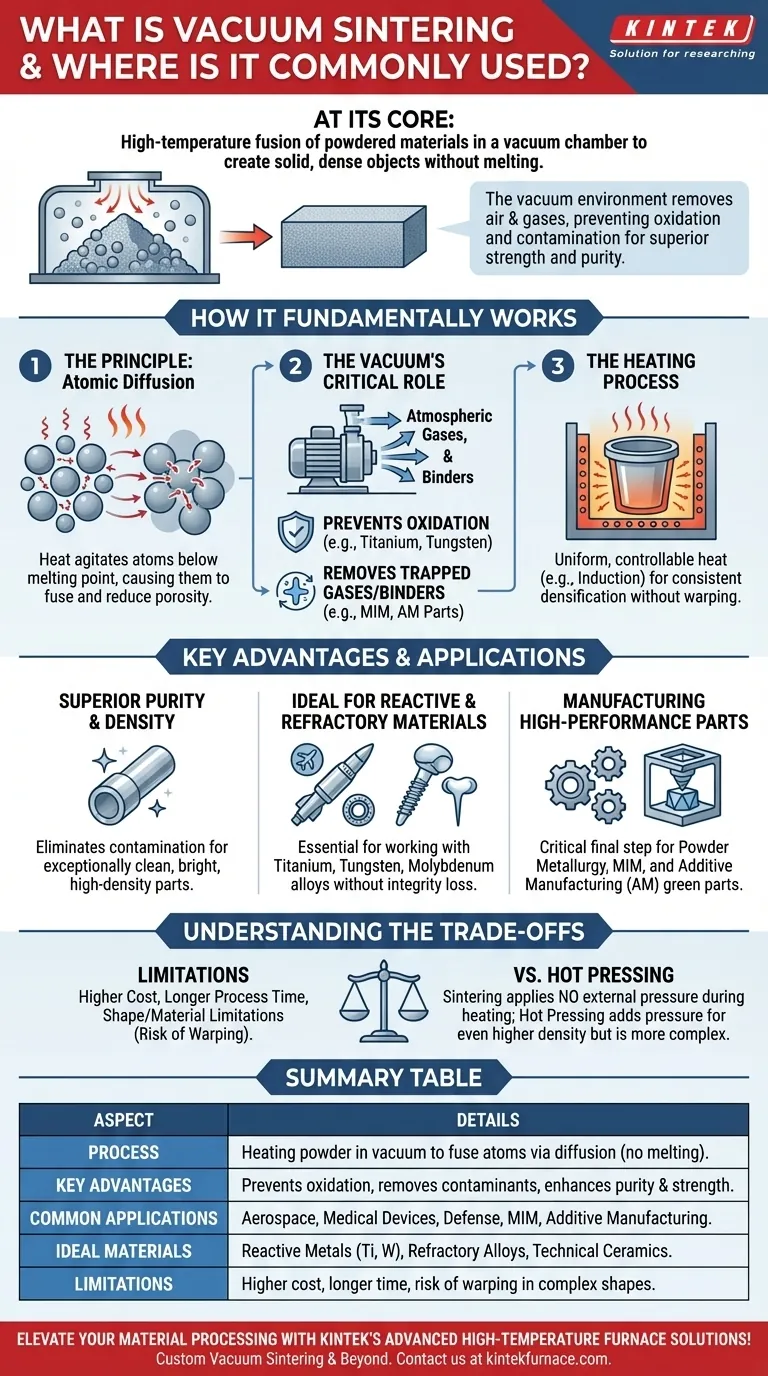

How Vacuum Sintering Fundamentally Works

To understand its applications, you must first understand the principles that make this process unique. It's a combination of physics and material science happening under very specific conditions.

The Principle of Sintering

Sintering is not melting. Instead, it relies on a phenomenon called atomic diffusion. When a compacted powder is heated to a temperature below its melting point, its atoms become highly agitated.

This energy allows atoms to migrate across the boundaries between individual powder particles, causing the particles to fuse together. This fusion reduces the empty space (porosity) between particles, resulting in a solid, densified part.

The Critical Role of the Vacuum

The vacuum environment is the key differentiator. Removing the atmosphere from the furnace accomplishes two essential goals.

First, it prevents oxidation and contamination. Many advanced materials, especially reactive metals like titanium or refractory metals like tungsten, will instantly form oxides when heated in the presence of oxygen. These oxide layers inhibit proper bonding and create weak points in the final material.

Second, it removes trapped gases and binders. Parts destined for sintering, particularly those from metal injection molding (MIM) or 3D printing, often contain binder agents. The vacuum helps pull these volatile compounds out of the part before the final sintering phase, ensuring a pure final product.

The Heating Process

Vacuum sintering furnaces use advanced heating methods, such as medium-frequency induction, to generate clean, controllable heat.

The powdered part, often held in a graphite or tungsten crucible, is heated uniformly through thermal radiation. This precise temperature control is crucial for achieving consistent densification without causing the part to warp, slump, or melt.

Key Advantages and Applications

The unique characteristics of the vacuum sintering process make it indispensable for several high-tech industries and advanced manufacturing methods.

Superior Material Purity and Density

Because it eliminates atmospheric contamination, vacuum sintering produces exceptionally clean and bright parts. This purity, combined with the reduction in porosity, leads to components with high density and excellent mechanical properties.

Ideal for Reactive and Refractory Materials

This is arguably the most important application. Materials like tungsten, molybdenum, and titanium alloys are vital for aerospace, medical, and defense applications but are extremely difficult to work with.

Vacuum sintering is one of the few viable methods for consolidating these materials into solid forms without compromising their integrity.

Manufacturing High-Performance Parts

The process is a critical final step for several modern manufacturing technologies.

It is used to transform the fragile "green parts" from powder metallurgy, metal injection molding (MIM), and additive manufacturing (AM) into fully dense, functional components. This results in seamless, joint-free parts that are near their final shape, minimizing waste.

Understanding the Trade-offs

While powerful, vacuum sintering is not a universal solution. An objective assessment requires understanding its limitations.

Process Time and Cost

Vacuum furnaces are sophisticated and expensive pieces of equipment. The process itself can be lengthy, as it involves pulling a vacuum, executing a carefully controlled heating and cooling cycle, and backfilling the chamber. This makes it more costly and time-consuming than conventional atmospheric sintering.

Material and Shape Limitations

The process requires precise control over temperature ramps and holds to prevent thermal stress and distortion. Very complex or delicate geometries can be prone to slumping or warping if the sintering cycle and part support are not designed perfectly.

Sintering vs. Hot Pressing

It's important to distinguish vacuum sintering from vacuum hot pressing. While both occur in a vacuum, hot pressing applies external mechanical pressure during heating. This can achieve even higher densities but is typically limited to simpler shapes and can be even more complex and expensive.

Making the Right Choice for Your Goal

Selecting the right thermal process depends entirely on your material and performance requirements.

- If your primary focus is high performance with reactive metals (e.g., titanium, refractory alloys): Vacuum sintering is often the only viable choice to prevent contamination and ensure the material's inherent properties are preserved.

- If your primary focus is achieving maximum density and purity in technical ceramics or powdered metals: The vacuum environment is critical for removing contaminants and binders, leading to a superior, high-density final product.

- If your primary focus is finalizing parts from additive manufacturing or MIM: Vacuum sintering is the industry-standard method for consolidating the powdered material into a strong, functional component.

Ultimately, choosing vacuum sintering is a decision to prioritize material integrity and performance above all else.

Summary Table:

| Aspect | Details |

|---|---|

| Process | Heating powdered materials in a vacuum to fuse atoms via diffusion without melting. |

| Key Advantages | Prevents oxidation, removes contaminants, enhances purity, strength, and density. |

| Common Applications | Aerospace, medical devices, defense, powder metallurgy, MIM, and additive manufacturing. |

| Ideal Materials | Reactive metals (e.g., titanium, tungsten), refractory alloys, and technical ceramics. |

| Limitations | Higher cost, longer process times, risk of warping in complex shapes. |

Elevate your material processing with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable options like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements for vacuum sintering and beyond. Contact us today to discuss how we can enhance your lab's efficiency and achieve superior results!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- Why is a vacuum hot press sintering furnace required for nanocrystalline ceramics? Preserve Structure with Pressure

- How do vacuum sintering and annealing furnaces contribute to the densification of NdFeB magnets?

- What is the mechanism of a vacuum sintering furnace for AlCoCrFeNi2.1 + Y2O3? Optimize Your High-Entropy Alloy Processing

- What is the function of a vacuum sintering furnace in CoNiCrAlY coatings? Repairing Cold-Sprayed Microstructures

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness