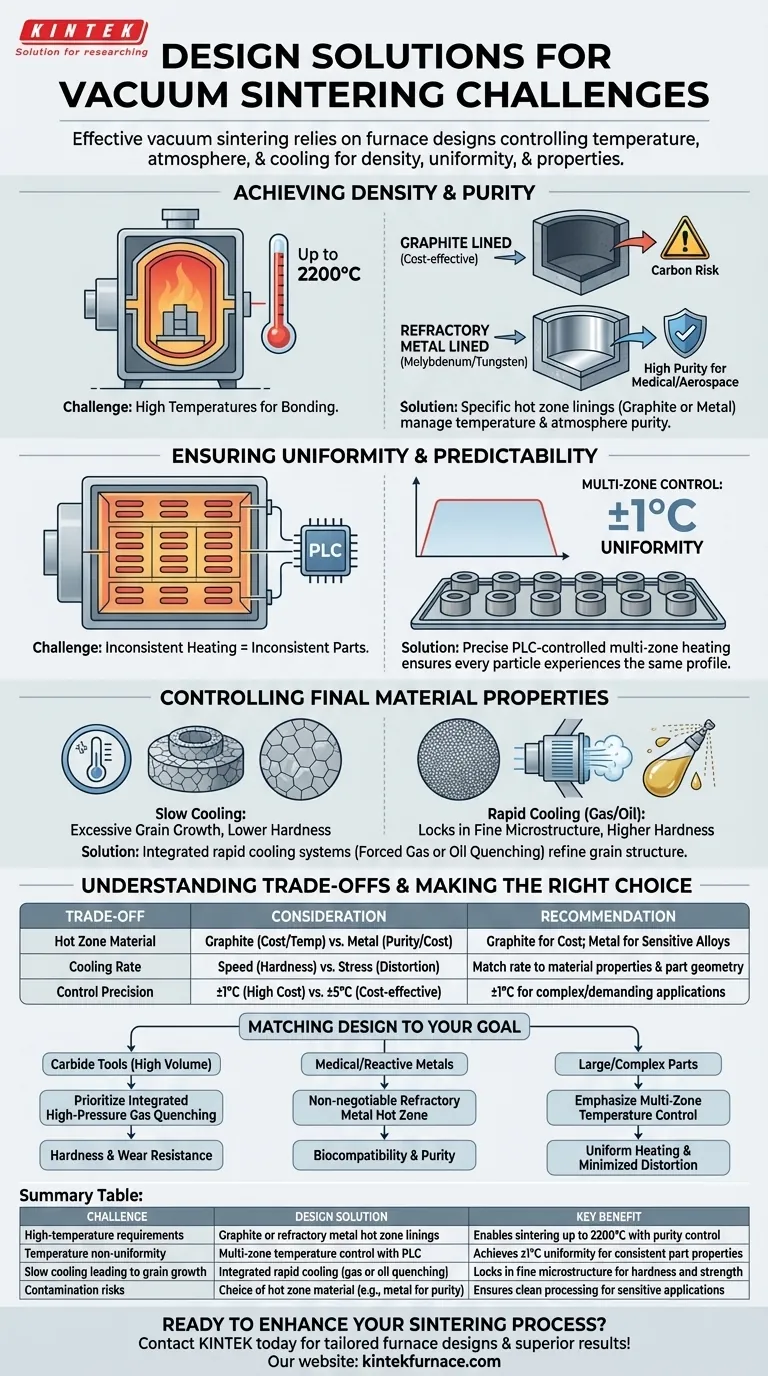

In short, effective vacuum sintering relies on specific furnace design solutions engineered to control temperature, atmosphere, and cooling. Key features include high-temperature hot zones with graphite or refractory metal linings, precise multi-zone temperature control for uniformity, and integrated rapid cooling systems like gas or oil quenching to achieve the desired final material properties.

The core challenge in vacuum sintering is not just heating a part, but precisely managing the entire thermal cycle to ensure particles bond correctly without contamination. The right furnace design transforms sintering from a simple heating process into a predictable, highly-controlled manufacturing method for producing dense, high-performance components.

Achieving Full Density and Purity

The primary goal of sintering is to transform a porous "green" part into a solid, dense component. This requires high temperatures and a clean environment, both of which are direct functions of the furnace's core design.

The Role of the High-Temperature Hot Zone

A furnace's ability to reach and sustain the correct sintering temperature is fundamental. Materials like tungsten carbide require temperatures approaching 2200°C for effective particle bonding and densification.

The hot zone's lining is equally critical. A graphite-lined hot zone is a common and cost-effective solution, but it can introduce carbon into the atmosphere, which is detrimental to certain alloys.

For materials that are sensitive to carbon contamination, a refractory metal hot zone (using molybdenum or tungsten) is necessary. This ensures a cleaner processing environment, which is vital for medical, aerospace, and other high-purity applications.

Ensuring Uniformity and Predictability

Inconsistent heating leads to inconsistent parts. A part that is hotter in one area than another will have variations in density, grain size, and mechanical properties. This is a critical failure point in high-volume production.

The Power of Multi-Zone Control

To combat this, advanced vacuum furnaces employ multi-zone temperature control. The hot zone is divided into several independently managed heating areas, often controlled by a sophisticated PLC (Programmable Logic Controller).

This design allows the system to make micro-adjustments, ensuring that the entire workload achieves exceptional temperature uniformity, often within ±1°C. This precision guarantees that every particle, on every part, experiences the same thermal profile, leading to uniform bonding and predictable final properties.

Controlling Final Material Properties

The properties of a sintered part are determined by its microstructure, particularly its grain size. The cooling phase of the thermal cycle is where you lock in this structure.

The Impact of Rapid Cooling Systems

Allowing a part to cool slowly can lead to excessive grain growth, which often results in lower hardness and strength. To prevent this, many vacuum sintering furnaces integrate rapid cooling systems.

Forced gas quenching uses high-pressure inert gas (like argon or nitrogen) to cool parts quickly and uniformly. This is essential for refining the microstructure in materials like tungsten carbide, resulting in higher hardness and wear resistance.

In some cases, even faster cooling is needed. Oil quenching systems can be integrated to provide the most aggressive cooling rates, though this is typically reserved for specific alloys that can withstand the high thermal stress.

Understanding the Trade-offs

Choosing the right design features involves balancing performance requirements with operational realities. There is no single "best" furnace design; there is only the best design for a specific application.

Hot Zone Material: Graphite vs. Metal

The choice between a graphite and a refractory metal hot zone is a primary trade-off. Graphite is less expensive and has a very high temperature ceiling, but poses a contamination risk. Refractory metals offer a much cleaner environment but are significantly more expensive and have operational limitations.

Cooling Rate: Speed vs. Stress

While rapid cooling is excellent for achieving hardness, it can introduce significant thermal stress. This can lead to distortion or even cracking in parts with complex geometries or thin walls. The cooling rate must be carefully matched to the material's properties and the part's design to avoid compromising its structural integrity.

Control Precision: Ideal vs. Practical

Achieving temperature uniformity of ±1°C requires more complex heating element design and sophisticated control systems, increasing the furnace's cost and complexity. For less demanding materials, a standard uniformity of ±5°C might be perfectly adequate and more cost-effective.

Making the Right Choice for Your Goal

Your material and final part requirements should dictate the furnace design you need.

- If your primary focus is high-volume production of carbide tools: Prioritize a furnace with an integrated, high-pressure gas quenching system to ensure hardness and wear resistance.

- If your primary focus is sintering medical-grade titanium or reactive metals: A furnace with a refractory metal hot zone is non-negotiable to prevent carbon contamination and ensure biocompatibility.

- If your primary focus is producing large or geometrically complex parts: Emphasize multi-zone temperature control to guarantee uniform heating and minimize the risk of thermal distortion during cooling.

Ultimately, a modern vacuum furnace is a precision instrument designed to deliver repeatable metallurgical outcomes.

Summary Table:

| Challenge | Design Solution | Key Benefit |

|---|---|---|

| High-temperature requirements | Graphite or refractory metal hot zone linings | Enables sintering up to 2200°C with purity control |

| Temperature non-uniformity | Multi-zone temperature control with PLC | Achieves ±1°C uniformity for consistent part properties |

| Slow cooling leading to grain growth | Integrated rapid cooling (gas or oil quenching) | Locks in fine microstructure for hardness and strength |

| Contamination risks | Choice of hot zone material (e.g., metal for purity) | Ensures clean processing for sensitive applications |

Ready to enhance your sintering process with precision furnace solutions? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're producing carbide tools, medical-grade metals, or complex parts, we can help you achieve superior density, purity, and performance. Contact us today to discuss your needs and discover how our tailored designs can optimize your results!

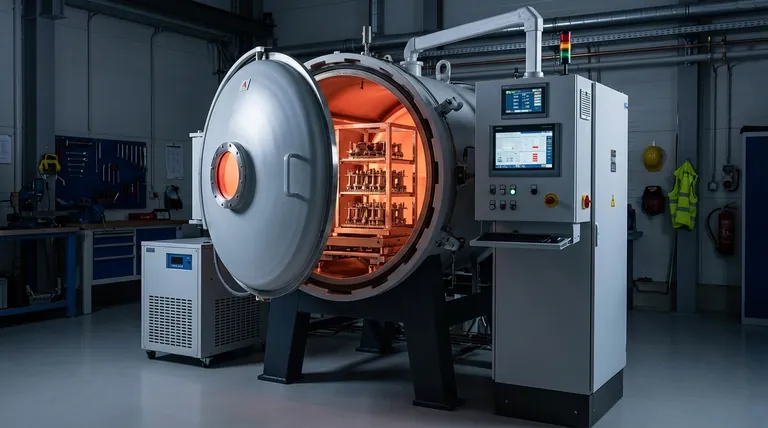

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What tasks does a high-temperature vacuum sintering furnace perform for PEM magnets? Achieve Peak Density

- What is the purpose of a 1400°C heat treatment for porous tungsten? Essential Steps for Structural Reinforcement

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion