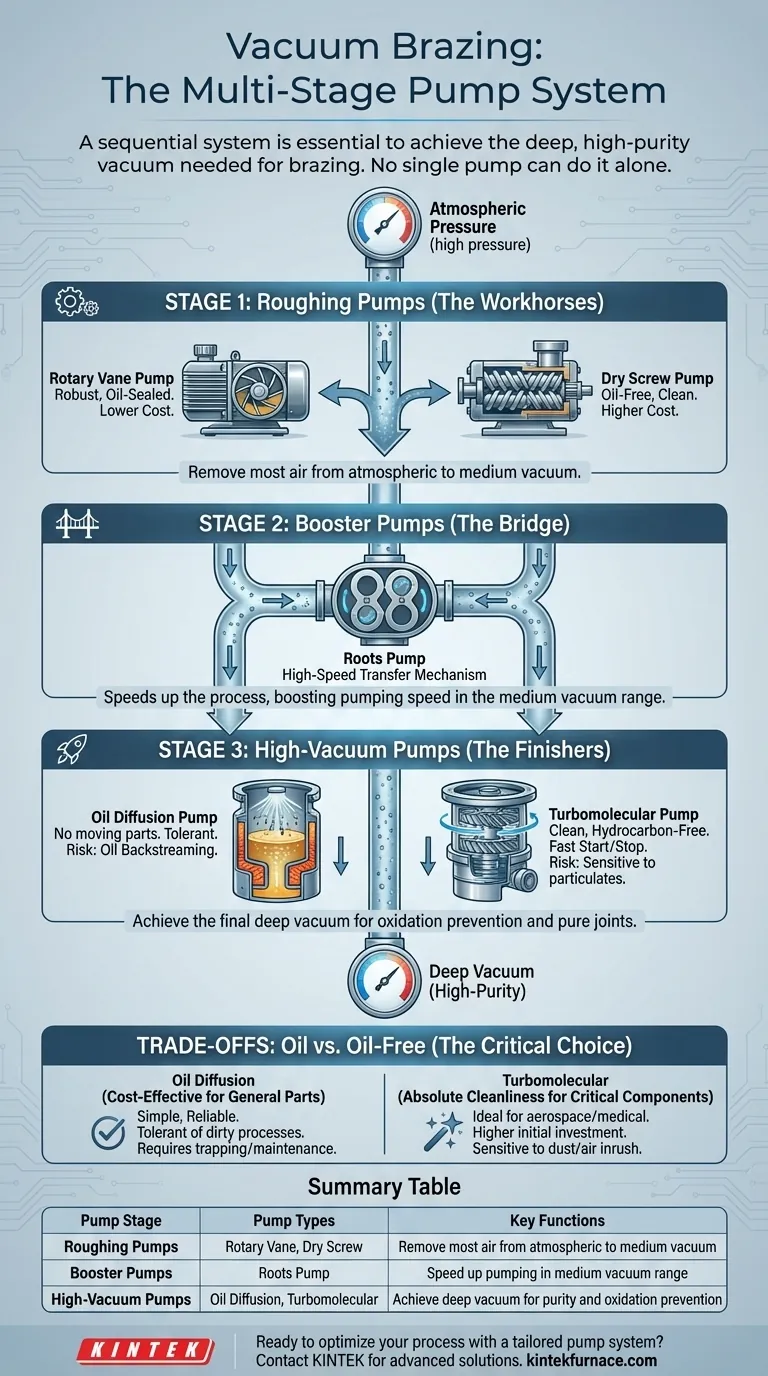

For vacuum brazing, a multi-stage system of pumps is required, not just a single type. The process typically begins with a roughing pump (like a rotary vane or dry screw pump) often paired with a Roots booster, which then hands off to a high-vacuum pump, such as an oil diffusion or turbomolecular pump, to achieve the final required vacuum level.

The core principle is that no single pump can efficiently move air from atmospheric pressure down to the deep vacuum needed for high-purity brazing. Instead, a system of specialized pumps works in successive stages, each optimized for a specific pressure range.

The Staged Approach to Creating a Vacuum

Think of creating a vacuum not as a single action, but as a journey through different pressure regimes. Each stage of the journey requires a different tool, or pump, designed to operate most effectively in that specific environment.

Stage 1: Roughing Pumps (The Workhorses)

The first step is to remove the vast majority of air molecules from the furnace chamber. This is the job of the roughing pump, which takes the pressure from atmospheric down to a medium vacuum level.

Two common types are used:

- Rotary Vane Pumps: These are traditional, oil-sealed pumps that offer robust performance at a lower initial cost.

- Dry Screw Pumps: These are oil-free pumps that eliminate the risk of oil contamination but come at a higher initial cost.

Stage 2: Booster Pumps (The Bridge)

To speed up the process and reach a deeper vacuum more quickly, a Roots pump (also called a mechanical booster) is almost always used in tandem with the roughing pump.

A Roots pump doesn't pump directly to the atmosphere. Instead, it acts as a high-speed transfer mechanism, grabbing large volumes of gas from the chamber and "boosting" them into the roughing pump, dramatically increasing the system's overall pumping speed in the medium vacuum range.

Stage 3: High-Vacuum Pumps (The Finishers)

Once the roughing and booster pumps have done their job, the high-vacuum pump takes over. This pump is what creates the extremely low-pressure environment (high vacuum) necessary to prevent oxidation and ensure a pure, strong braze joint.

The two primary choices are:

- Oil Diffusion Pumps: These pumps have no moving parts and work by boiling a special oil and directing the vapor stream to drag air molecules out of the system.

- Turbomolecular Pumps (TMPs): These work like a jet engine in reverse, using finely balanced, high-speed turbine blades to mechanically strike gas molecules and push them toward the exhaust.

Understanding the Trade-offs: Oil vs. Oil-Free

The choice between a diffusion pump and a turbomolecular pump is one of the most critical decisions, as it directly impacts process cleanliness and cost.

The Case for Oil Diffusion Pumps

Diffusion pumps are simple, highly reliable, and have a lower capital cost. They can handle high gas loads and are very tolerant of dirty processes.

However, they carry the risk of oil backstreaming, where oil vapor can travel back into the furnace and contaminate the parts. This requires careful trapping and maintenance, and they also need significant time to warm up and cool down.

The Case for Turbomolecular Pumps

Turbomolecular pumps provide a completely clean, hydrocarbon-free vacuum, making them ideal for sensitive applications like aerospace, medical, and electronics where contamination is unacceptable. They also start and stop very quickly.

The main drawbacks are a higher initial investment and a greater sensitivity to dust, particulates, and sudden air inrushes, which can damage the delicate high-speed blades.

Making the Right Choice for Your Goal

Your selection of a pump system should be dictated by the specific requirements of your brazing application.

- If your primary focus is cost-effectiveness for general industrial parts: A system using a rotary vane pump, Roots booster, and a well-trapped oil diffusion pump is a proven and economical solution.

- If your primary focus is absolute cleanliness for critical components (e.g., aerospace, medical): A fully oil-free system using a dry screw pump, Roots booster, and a turbomolecular pump is the definitive choice.

Understanding how these pump systems work together empowers you to achieve flawless, high-integrity joints every time.

Summary Table:

| Pump Stage | Pump Types | Key Functions |

|---|---|---|

| Roughing Pumps | Rotary Vane, Dry Screw | Remove most air from atmospheric to medium vacuum |

| Booster Pumps | Roots Pump | Speed up pumping in medium vacuum range |

| High-Vacuum Pumps | Oil Diffusion, Turbomolecular | Achieve deep vacuum for purity and oxidation prevention |

Ready to optimize your vacuum brazing process with a tailored pump system? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how we can enhance your brazing quality and efficiency!

Visual Guide

Related Products

- Ultra Vacuum Electrode Feedthrough Connector Flange Power Lead for High Precision Applications

- Molybdenum Vacuum Heat Treat Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 304 316 Stainless Steel High Vacuum Ball Stop Valve for Vacuum Systems

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What role do the exhaust branch pipes at the top of a vacuum chamber play? Optimize Your Pressure Control Today

- Why is a high vacuum system critical for sealing the quartz tube used in Fe3GeTe2 single crystal preparation?

- What materials are used for the heating elements in a vacuum furnace? Choose the Right Element for Your High-Temp Needs

- What design considerations are important for custom vacuum chambers? Optimize for Performance, Cost, and Application Needs

- What are the main technical requirements for vacuum pumps in vacuum sintering furnaces? Ensure Material Purity and Efficiency