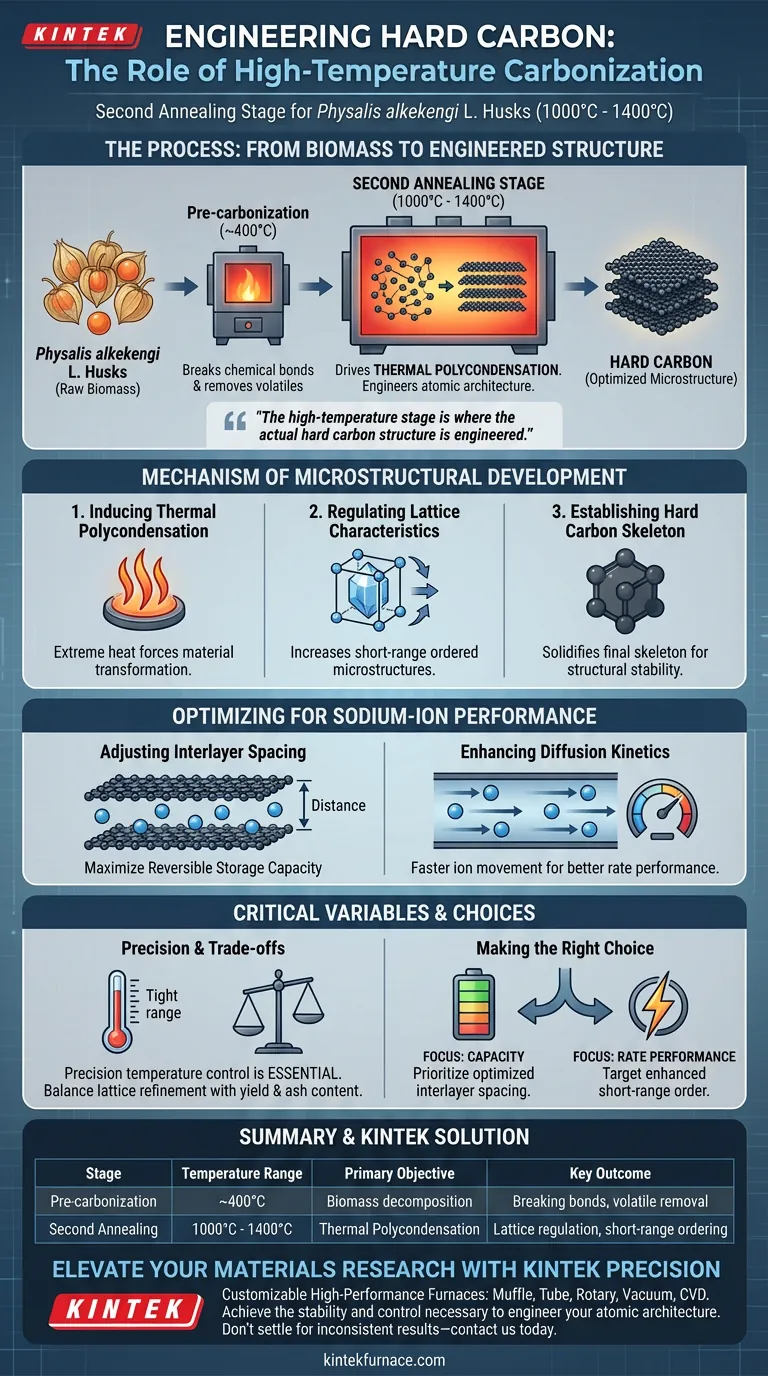

The primary objective of using a high-temperature carbonization furnace in the second annealing stage is to drive thermal polycondensation, a critical transformation that determines the final microstructure of the hard carbon. Operating typically between 1000 °C and 1400 °C, this specific thermal treatment regulates the carbon lattice to optimize the material for electrochemical applications.

The initial low-temperature stage merely breaks down raw biomass; this high-temperature stage is where the actual hard carbon structure is engineered. By precisely controlling heat, you define the atomic spacing and order required for efficient sodium-ion storage and diffusion.

The Mechanism of Microstructural Development

Inducing Thermal Polycondensation

The second annealing stage subjects the material to extreme heat, specifically within the range of 1000 °C to 1400 °C.

Unlike the initial 400 °C pre-carbonization step—which simply breaks chemical bonds in the biomass—this higher temperature forces the material to undergo thermal polycondensation.

Regulating Lattice Characteristics

The intense heat allows for the precise manipulation of the carbon layers' lattice characteristics.

This process transforms the disordered precursor into a material with increased short-range ordered microstructures.

Establishing the Hard Carbon Skeleton

While earlier stages remove volatile components, the high-temperature furnace solidifies the final material skeleton.

This structural stability is essential for determining how the material will behave during electrochemical cycling.

Optimizing for Sodium-Ion Performance

Adjusting Interlayer Spacing

The defining goal of this stage is to optimize the distance between carbon layers.

By tuning this interlayer spacing, the furnace creates an environment that maximizes the reversible storage capacity for sodium ions.

Enhancing Diffusion Kinetics

The microstructural changes induced at these temperatures directly impact how fast ions can move through the material.

Properly developed short-range order ensures that sodium-ion diffusion kinetics are efficient, leading to better rate performance in batteries.

Critical Process Variables and Trade-offs

The Necessity of Precision

Achieving the desired microstructure relies entirely on the ability to maintain precise temperature control.

As noted in broader contexts, fluctuations in temperature can alter the kinetics of volatile release and impact the consistency of the final product.

Balancing Structure and Yield

While high temperatures refine the lattice, they must be balanced against yield and ash content considerations.

Inconsistent heating rates or isothermal conditions can lead to variations in atomic ratios, compromising the material's reliability across production batches.

Making the Right Choice for Your Goal

To maximize the potential of Physalis alkekengi L. husks, you must align the furnace parameters with your specific performance targets.

- If your primary focus is Capacity: Prioritize temperatures that optimize interlayer spacing to maximize the volume of sodium ions the structure can accommodate.

- If your primary focus is Rate Performance: Target temperatures that enhance short-range order to facilitate faster diffusion kinetics for rapid charging and discharging.

Precise high-temperature regulation is not just a heating step; it is the definitive tool for engineering the atomic architecture of high-performance hard carbon.

Summary Table:

| Stage | Temperature Range | Primary Objective | Key Structural Outcome |

|---|---|---|---|

| Pre-carbonization | ~400°C | Biomass decomposition | Breaking chemical bonds & volatile removal |

| Second Annealing | 1000°C - 1400°C | Thermal Polycondensation | Lattice regulation & short-range ordering |

| Structural Goal | Variable | Interlayer Spacing | Optimized sodium-ion storage & kinetics |

Elevate Your Materials Research with KINTEK Precision

High-performance hard carbon requires more than just heat; it demands the absolute precision of engineered thermal cycles. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as other lab high-temperature furnaces, all customizable to your unique research needs.

Whether you are optimizing interlayer spacing for capacity or refining short-range order for rate performance, our systems provide the stability and control necessary to engineer your atomic architecture. Don’t settle for inconsistent results—contact us today to find the perfect furnace solution for your laboratory.

Visual Guide

References

- Liying Liu, Yang Xu. Hard carbon derived from <i>Physalis alkekengi</i> L. husks as a stable anode for sodium-ion batteries. DOI: 10.1039/d4me00007b

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What makes temperature measurement easier in a vertical vacuum furnace? Achieve Precise Thermal Control for Your Lab

- How does a high-temperature vacuum furnace facilitate the transparency of magnesium aluminum spinel ceramics?

- What is the significance of vacuum sintering in metal processing, and how do continuous vacuum furnaces facilitate it? Unlock High-Purity Metal Parts

- Why is Spark Plasma Sintering (SPS) optimal for Ti2AlN ceramics? Achieving 99.2% Purity and Maximum Density

- Why is a high vacuum system necessary when using SPS for Ti-6Al-4V composites? Ensure Material Integrity

- What is the purpose of using industrial heating during non-productive vacuum degassing phases? Protect Your Assets

- What is the burnout cycle on a vacuum furnace? A Key to High-Purity Heat Treating

- What are the key design features of a vacuum graphitizing furnace? Achieving High-Purity Graphitization