The necessity of a high vacuum system in Spark Plasma Sintering (SPS) for Ti-6Al-4V composites is driven by the alloy's extreme chemical reactivity at elevated temperatures. Without this vacuum, the titanium matrix will rapidly absorb oxygen and nitrogen from the atmosphere, causing immediate oxidation and compromising the structural integrity of the composite.

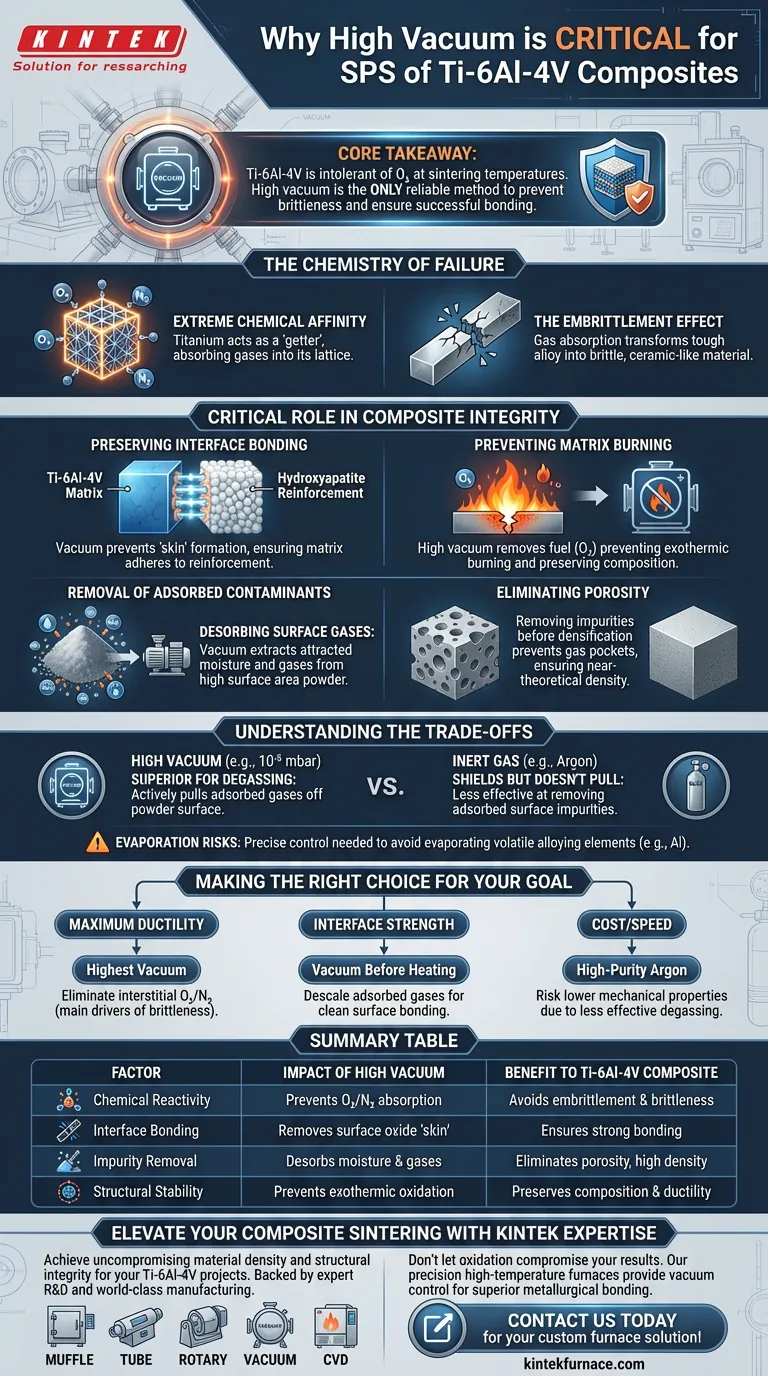

Core Takeaway Ti-6Al-4V is fundamentally intolerant of oxygen at sintering temperatures. A high vacuum environment is the only reliable method to prevent the material from becoming brittle and to ensure the titanium matrix bonds successfully with reinforcement materials like hydroxyapatite.

The Chemistry of Failure

The primary reason for utilizing high vacuum lies in the inherent behavior of titanium alloys when heated.

Extreme Chemical Affinity

Titanium is a "getter" material. At the high temperatures required for sintering, Ti-6Al-4V acts like a sponge for atmospheric gases. It does not merely react on the surface; it actively absorbs oxygen and nitrogen into its crystal lattice.

The Embrittlement Effect

When Ti-6Al-4V absorbs these gases, the material undergoes embrittlement. The presence of oxides and nitrides restricts the movement of dislocations within the metal's structure. This transforms a tough, ductile alloy into a brittle ceramic-like material that is prone to catastrophic fracture under stress.

Critical Role in Composite Integrity

When creating a composite (specifically Ti-6Al-4V combined with materials like hydroxyapatite), the vacuum serves a dual purpose beyond simple oxidation prevention.

Preserving Interface Bonding

For a composite to function, the matrix (Ti-6Al-4V) must chemically bond with the reinforcement (hydroxyapatite). Oxidation acts as a barrier. If the titanium surface oxidizes before sintering is complete, it forms an inert "skin" that prevents it from adhering to the reinforcement, resulting in a composite that falls apart under load.

Preventing Matrix Burning

In extreme cases, the reaction between hot titanium and atmospheric oxygen can be exothermic enough to cause the matrix material to effectively "burn." A high vacuum removes the fuel (oxygen) for this reaction, preserving the stoichiometry of the Ti-6Al-4V and ensuring the final chemical composition matches the design standards.

Removal of Adsorbed Contaminants

While preventing atmospheric oxidation is the primary goal, the vacuum performs a secondary, equally critical function regarding the raw powder.

Desorbing Surface Gases

Metal powders have a high surface area that naturally attracts and holds moisture and gases (adsorption). If these are not removed prior to densification, they become trapped inside the final part.

Eliminating Porosity

A high vacuum extracts these adsorbed gases as the temperature rises. By removing these impurities before the material densifies, the system prevents the formation of gas pockets (porosity) and ensures the final component achieves near-theoretical density.

Understanding the Trade-offs

While high vacuum is critical, it is important to understand the operational nuances and potential pitfalls.

Vacuum vs. Inert Gas

While some processes use inert gas (like Argon) to shield titanium, vacuum is often superior for degassing. Inert gas can shield the part from outside air, but it does not actively "pull" adsorbed gases off the powder surface as effectively as a high vacuum system (e.g., $10^{-5}$ mbar).

Evaporation Risks

High vacuum lowers the boiling point of certain elements. While Ti-6Al-4V is generally stable, extreme vacuum combined with extreme heat can potentially lead to the evaporation of volatile alloying elements (like Aluminum) if not carefully controlled. This requires precise management of heating rates, a benefit inherent to the SPS process.

Making the Right Choice for Your Goal

The specific atmosphere you choose depends on the critical requirements of your final composite.

- If your primary focus is Maximum Ductility: Prioritize the highest possible vacuum level to eliminate interstitial oxygen and nitrogen, which are the main drivers of brittleness.

- If your primary focus is Interface Strength: Ensure the vacuum is applied before heating begins to descale adsorbed gases, guaranteeing a clean surface for the Ti-6Al-4V and hydroxyapatite to bond.

- If your primary focus is Cost/Speed: You might consider high-purity Argon, but be aware that you risk lower mechanical properties due to less effective removal of adsorbed surface impurities compared to vacuum.

In summary, a high vacuum system is not just a protective measure; it is a manufacturing prerequisite for Ti-6Al-4V composites to ensure the material retains its metallic properties rather than degrading into a brittle oxide.

Summary Table:

| Factor | Impact of High Vacuum | Benefit to Ti-6Al-4V Composite |

|---|---|---|

| Chemical Reactivity | Prevents absorption of O2 and N2 | Avoids material embrittlement and brittleness |

| Interface Bonding | Removes surface oxide "skin" | Ensures strong bonding between matrix and reinforcement |

| Impurity Removal | Desorbs moisture and surface gases | Eliminates internal porosity for near-theoretical density |

| Structural Stability | Prevents exothermic oxidation | Preserves stoichiometric composition and ductility |

Elevate Your Composite Sintering with KINTEK Expertise

Achieve uncompromising material density and structural integrity for your Ti-6Al-4V projects. Backed by expert R&D and world-class manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to meet your unique laboratory or industrial requirements.

Don't let oxidation compromise your results. Whether you are developing medical implants or aerospace components, our precision high-temperature furnaces provide the vacuum control necessary for superior metallurgical bonding.

Ready to optimize your SPS process? Contact us today to discuss your custom furnace solution!

Visual Guide

References

- Reinhold Schneider, Christof Sommitsch. Partitioning Phenomena During the Heat Treatment of Martensitic Stainless Steels. DOI: 10.1515/htm-2025-0014

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What operational advantages do vacuum furnaces provide? Achieve Superior Material Quality and Process Control

- How is a laboratory vacuum drying oven utilized in the production of shape-stabilized phase change materials?

- What types of heating elements are used in vacuum sintering furnaces? Choose the Right One for High-Temp Success

- Why is vacuum-pressure treatment equipment required for deep wood impregnation? Unlock Ultimate Material Durability

- What are the advantages of using an optical floating-zone furnace for growing RCu series? Achieve High-Purity Growth

- What types of pumps are used for vacuum brazing? Master the Staged System for High-Purity Brazing

- What are the advantages of vacuum heat treatment? Achieve Superior Cleanliness and Performance for Critical Parts

- How is an ultra-high temperature furnace reaching 1,673 K utilized in PVC dechlorination? Bridging Waste to Ironmaking