The fundamental advantage of vacuum heat treatment is its ability to produce exceptionally clean parts with superior mechanical properties by eliminating atmospheric contamination during the process. By removing air and other gases from the furnace, the treatment prevents oxidation, decarburization, and other surface reactions that can compromise the integrity and performance of metal components.

The core value of vacuum heat treatment is not just preventing negative reactions, but enabling a level of process control that is unattainable with conventional methods. This precision translates directly into higher part quality, improved performance, and reduced need for costly post-processing.

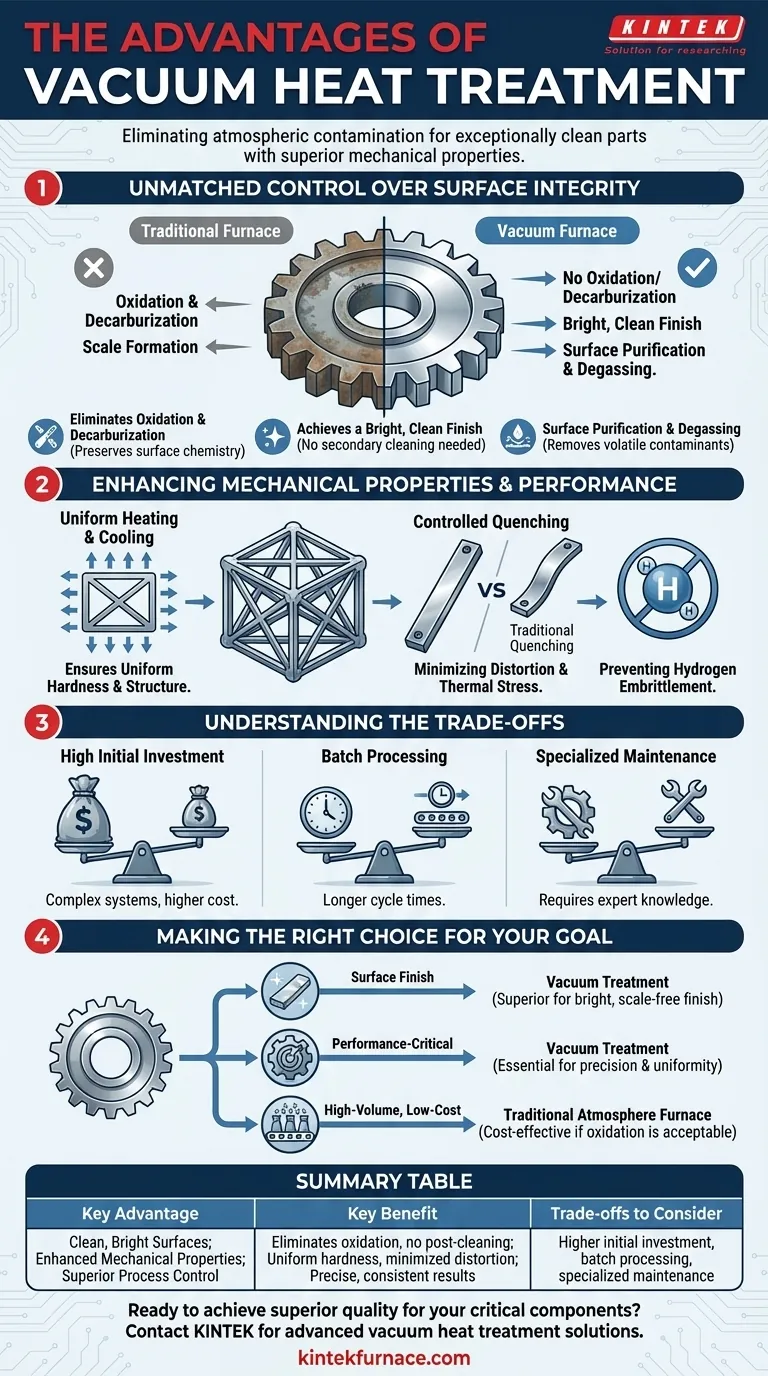

Unmatched Control Over Surface Integrity

The most visible benefit of vacuum heat treatment is its effect on the part's surface. Operating in a near-perfect vacuum fundamentally changes how the metal responds to high temperatures.

Eliminating Oxidation and Decarburization

In a traditional furnace, the oxygen present in the air reacts with the hot metal surface, forming a layer of oxide scale. This process can also lead to decarburization, where carbon is lost from the surface of the steel, softening it.

A vacuum environment is virtually free of oxygen, completely preventing oxidation and decarburization. This preserves the material's inherent surface chemistry and integrity.

Achieving a Bright, Clean Finish

Because no scale is formed, parts emerge from a vacuum furnace with a bright, clean, and often shiny surface.

This eliminates the need for secondary cleaning operations like sandblasting, chemical pickling, or grinding, which saves time, reduces cost, and avoids further mechanical stress on the part.

Surface Purification and Degassing

The vacuum not only prevents contamination but can also actively clean the part. Under vacuum, volatile contaminants and trapped gases on or within the material's surface are drawn out and removed.

This degassing effect results in a metallurgically purer surface, which is critical for applications requiring strong bonds, such as brazing or welding.

Enhancing Mechanical Properties and Performance

Control over the furnace environment translates directly to control over the final material properties. This ensures parts are not only clean but also perform to their maximum potential.

Ensuring Uniform Hardness and Structure

Vacuum furnaces provide extremely uniform heating and cooling. With no air currents to create hot or cold spots, the entire part reaches the target temperature at the same rate.

This uniformity is critical for achieving consistent metallurgical structures and predictable hardness across the entire component, from the thin sections to the thickest.

Minimizing Distortion and Thermal Stress

Controlled cooling, often using high-pressure inert gas quenching within the vacuum chamber, allows for a more uniform and less severe quench than oil or water.

This dramatically reduces thermal stress and minimizes distortion or warping, ensuring parts maintain their dimensional accuracy. This is especially vital for complex or high-precision components.

Preventing Hydrogen Embrittlement

Certain processes can introduce hydrogen into a metal's structure, causing it to become brittle and fail under stress.

Vacuum heat treatment creates a hydrogen-free environment, effectively preventing hydrogen embrittlement and ensuring the material's ductility and toughness are preserved.

Understanding the Trade-offs

While the advantages are significant, vacuum heat treatment is not a universal solution. An objective assessment requires understanding its limitations.

High Initial Capital Investment

Vacuum furnaces are complex systems that represent a significantly higher initial investment compared to conventional atmosphere or air furnaces. The cost of the chamber, pumping systems, and control instrumentation is substantial.

Batch Processing and Cycle Times

Vacuum heat treatment is inherently a batch process. Loading parts, pumping down the chamber to the required vacuum level, processing, and cooling can result in longer overall cycle times compared to continuous furnace operations.

Specialized Maintenance Requirements

The high-vacuum pumps, seals, and advanced control systems demand specialized knowledge for operation and maintenance. Keeping the system leak-free and calibrated is critical for achieving consistent results.

Making the Right Choice for Your Goal

Selecting the appropriate heat treatment method depends entirely on your project's specific requirements for cost, quality, and performance.

- If your primary focus is surface finish and component cleanliness: Vacuum treatment is the superior choice for parts that require a bright, scale-free finish with no post-processing.

- If your primary focus is performance-critical components: The process control, uniformity, and reduced distortion of vacuum treatment are essential for aerospace, medical, or high-performance tooling applications.

- If your primary focus is high-volume, low-cost production: A traditional atmosphere furnace may be more cost-effective for components where surface oxidation is acceptable or can be easily removed.

Ultimately, adopting vacuum heat treatment is an investment in process control, repeatability, and the final quality of your most critical parts.

Summary Table:

| Key Advantage | Key Benefit |

|---|---|

| Clean, Bright Surfaces | Eliminates oxidation & decarburization; no post-cleaning needed. |

| Enhanced Mechanical Properties | Uniform hardness, minimized distortion, and prevention of hydrogen embrittlement. |

| Superior Process Control | Precise, uniform heating and cooling for consistent, high-quality results. |

| Trade-offs to Consider | Higher initial investment, batch processing, and specialized maintenance. |

Ready to achieve superior quality for your critical components?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements like yours.

Contact us today to discuss how our vacuum heat treatment solutions can enhance your part performance and streamline your production.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity

- What is the heat treatment in a vacuum furnace? Achieve Superior Metallurgical Properties

- How does vacuum heat treatment improve mechanical properties of metals? Enhance Strength and Durability

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What is the process of vacuum heat treatment? Achieve Superior Metallurgical Properties