In short, a vertical vacuum furnace simplifies temperature measurement primarily due to its physical configuration. The top-loading design provides direct, unobstructed overhead access to the entire workload, allowing for the easy and precise placement of thermocouple sensors in hard-to-reach areas, including the very center of the charge.

The ease of measuring temperature in a vertical furnace is more than a simple convenience. It is a fundamental design advantage that directly enables superior temperature uniformity, more accurate process control, and greater confidence in the final product quality.

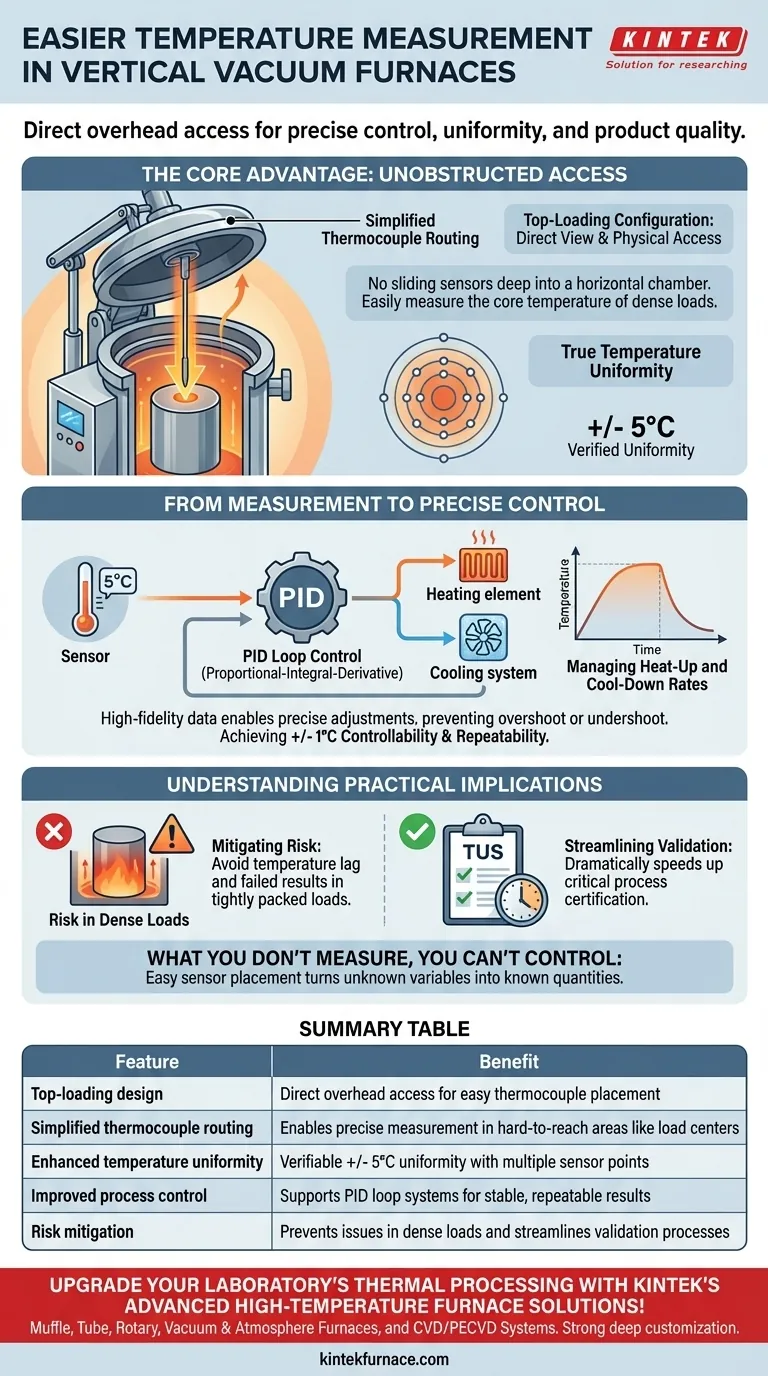

The Core Advantage: Unobstructed Access

The defining characteristic that facilitates temperature measurement in a vertical furnace is its top-down construction. Unlike horizontal furnaces where access is limited to one end, the vertical design opens up the entire chamber from above.

Top-Loading Configuration

Lifting the furnace lid provides a clear, top-down view and direct physical access to the workload below. This eliminates the challenge of trying to slide sensors deep into a horizontal chamber around or through the parts being processed.

Simplified Thermocouple Routing

With a vertical furnace, thermocouples can be strategically lowered from the top and guided directly into the most critical points of the charge. This makes it simple to measure the core temperature of a dense load, which is often the last area to reach the setpoint temperature.

Enabling True Temperature Uniformity

A furnace can be rated for high temperature uniformity, such as +/- 5°C, but this is meaningless if you cannot verify it. The ability to easily distribute multiple sensors throughout the load allows operators to confirm that the entire workload, from edge to core, is truly meeting the required temperature profile.

From Measurement to Precise Control

Accurate measurement is the foundation of effective control. The high-fidelity temperature data gathered from well-placed thermocouples allows the furnace's control system to perform optimally.

The Role of PID Loop Control

Modern furnaces use sophisticated control systems, like independent PID (Proportional-Integral-Derivative) loops, to manage heating. These systems are only as good as the data they receive. Accurate, real-time temperature feedback from the core of the load allows the controller to make precise adjustments, preventing overshoot or undershoot.

Achieving Controllability and Repeatability

Specifications like +/- 1°C controllability depend entirely on the quality of the temperature measurement. When the sensor accurately reflects the part's temperature, the control system can maintain a highly stable and repeatable thermal process, batch after batch.

Managing Heat-Up and Cool-Down Rates

For sensitive materials, the rate of temperature change is just as important as the final temperature. Placing thermocouples strategically allows the system to precisely manage these ramps, ensuring the part heats or cools evenly and preventing thermal shock.

Understanding the Practical Implications

Failing to measure temperature correctly isn't just a data error; it's a direct risk to process integrity and product quality. The vertical furnace's design inherently mitigates these risks.

Mitigating Risk in Dense Loads

In a tightly packed load, the outer parts can insulate the inner parts, creating a significant temperature lag. Without a sensor at the core, the process might finish before the center of the load has reached the required temperature, leading to inconsistent or failed results.

Streamlining Process Validation

Industries requiring certification (like aerospace) mandate regular Temperature Uniformity Surveys (TUS), which involve placing numerous thermocouples throughout the furnace's working volume. The direct access of a vertical furnace dramatically simplifies and speeds up this critical validation process.

What You Don't Measure, You Can't Control

This core engineering principle is paramount in thermal processing. If a cold spot exists but you have no sensor there, your control system is blind to the problem. Easy sensor placement turns unknown variables into known quantities.

How to Apply This to Your Process

Choosing a furnace configuration should be guided by the specific demands of your application and quality requirements.

- If your primary focus is process repeatability and quality assurance: The vertical design's superior measurement capability provides the high-fidelity data needed to guarantee consistent results.

- If you are processing dense, large, or complex-shaped parts: The ability to place thermocouples deep within the load is non-negotiable for ensuring the entire part achieves the correct metallurgical properties.

- If you require frequent process validation or certifications: A vertical furnace will simplify the setup for Temperature Uniformity Surveys, saving significant time, effort, and cost.

Ultimately, the vertical furnace's design turns temperature control from an assumption into a verifiable fact for every batch.

Summary Table:

| Feature | Benefit |

|---|---|

| Top-loading design | Direct overhead access for easy thermocouple placement |

| Simplified thermocouple routing | Enables precise measurement in hard-to-reach areas like load centers |

| Enhanced temperature uniformity | Verifiable +/- 5°C uniformity with multiple sensor points |

| Improved process control | Supports PID loop systems for stable, repeatable results |

| Risk mitigation | Prevents issues in dense loads and streamlines validation processes |

Upgrade your laboratory's thermal processing with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with strong deep customization to meet your unique experimental needs. Achieve precise temperature control and superior product quality—contact us today to discuss how our furnaces can enhance your process efficiency and reliability!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What is the process of vacuum heat treatment? Achieve Superior Metallurgical Properties

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- Where are vacuum furnaces used? Critical Applications in Aerospace, Medical, and Electronics

- What is the heat treatment in a vacuum furnace? Achieve Superior Metallurgical Properties

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing