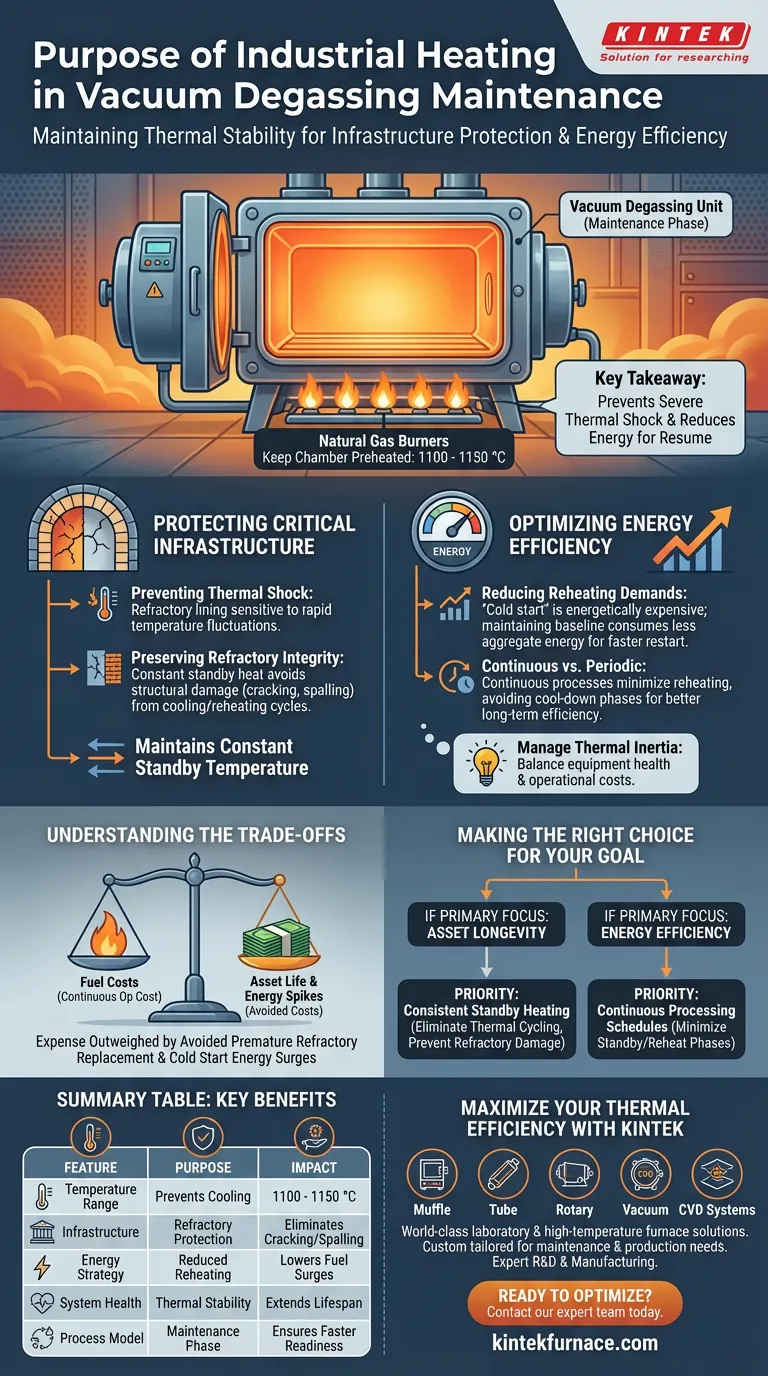

Industrial heating systems are critical for maintaining thermal stability during the non-productive phases of vacuum degassing operations. Specifically, natural gas burners are utilized during downtime to keep the vacuum chamber preheated to temperatures between 1100 and 1150 °C.

By maintaining high temperatures during standby, operators prevent severe thermal shock to the refractory lining and significantly reduce the energy required to resume production.

Protecting Critical Infrastructure

Preventing Thermal Shock

The refractory lining of a vacuum degassing unit is designed to withstand extreme heat, but it is highly sensitive to rapid temperature fluctuations.

If the unit were allowed to cool down completely during maintenance, the subsequent reheating process would create significant stress.

Preserving Refractory Integrity

Maintaing a constant standby temperature prevents this thermal shock.

By keeping the chamber between 1100 and 1150 °C, you avoid the structural damage—such as cracking or spalling—that often results from aggressive cooling and reheating cycles.

Optimizing Energy Efficiency

Reducing Reheating Demands

It may seem counterintuitive to consume fuel during a non-productive phase, but a "cold start" is energetically expensive.

Reheating a massive industrial vessel from ambient temperature to operating levels requires a tremendous surge of energy.

maintaining a steady baseline temperature ensures that the transition back to formal production is faster and consumes less aggregate energy.

Continuous vs. Periodic Processing

This thermal principle explains why continuous degassing processes are generally preferred over periodic ones.

Continuous operations minimize the frequency of reheating cycles.

By avoiding the cool-down phase entirely, continuous processes act as a more energy-efficient model for long-term production.

Understanding the Trade-offs

Balancing Fuel Costs and Asset Life

While preheating is technically superior, it does incur a continuous operational cost.

Operators must account for the consumption of natural gas or other fuels during downtime, even when no product is being improved.

However, this expense is almost always outweighed by the avoided costs of premature refractory replacement and the energy spikes associated with cold starts.

Making the Right Choice for Your Goal

To maximize the lifespan and efficiency of your vacuum degassing unit, align your heating strategy with your operational priorities.

- If your primary focus is Asset Longevity: Prioritize consistent standby heating to eliminate thermal cycling stress and prevent damage to expensive refractory linings.

- If your primary focus is Energy Efficiency: Shift towards continuous processing schedules to minimize the total number of standby or reheat phases required.

Managing thermal inertia is the key to balancing equipment health with operational costs.

Summary Table:

| Feature | Standby Heating Purpose | Impact on Operations |

|---|---|---|

| Temperature Range | 1100 - 1150 °C | Prevents refractory cooling |

| Infrastructure | Refractory Protection | Eliminates cracking and spalling |

| Energy Strategy | Reduced Reheating | Lowers fuel surges during restart |

| System Health | Thermal Stability | Extends lifespan of degassing units |

| Process Model | Maintenance Phase | Ensures faster production readiness |

Maximize Your Thermal Efficiency with KINTEK

Protect your industrial infrastructure from the costly effects of thermal shock. KINTEK provides world-class laboratory and high-temperature furnace solutions designed to maintain precision and durability. Backed by expert R&D and manufacturing, we offer customizable Muffle, Tube, Rotary, Vacuum, and CVD systems tailored to your specific maintenance and production needs.

Ready to optimize your heating strategy and safeguard your refractory assets? Contact our expert team today to discover how our high-performance systems can streamline your operations.

Visual Guide

References

- Viacheslav A. Murashov, Dmitry D. Lvov. Steel degassing in continuous steel melting units. DOI: 10.18799/24131830/2024/1/4154

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What is the primary role of a vacuum annealing furnace? Optimize AlSi10Mg LPBF Microstructure and Conductivity

- What is the role of a vacuum furnace in the solid-phase synthesis of TiC/Cu? Master High-Purity Material Engineering

- What role do vacuum furnaces play in electronic component manufacturing? Essential for Purity and Precision

- How a High-Vacuum Brazing Furnace Enhances CuMnNi Thin Film Piezoresistivity through Precision Annealing

- What are the primary advantages of using a vacuum furnace for heat treatment? Achieve Purity and Precision for Superior Components

- What is vacuum sintering and what are its advantages? Unlock Superior Material Performance

- Why is an industrial vacuum drying oven indispensable for battery assembly? Protect Your Battery Life and Safety

- What gases in the air can dissolve into molten metal and cause defects? Prevent Porosity and Embrittlement