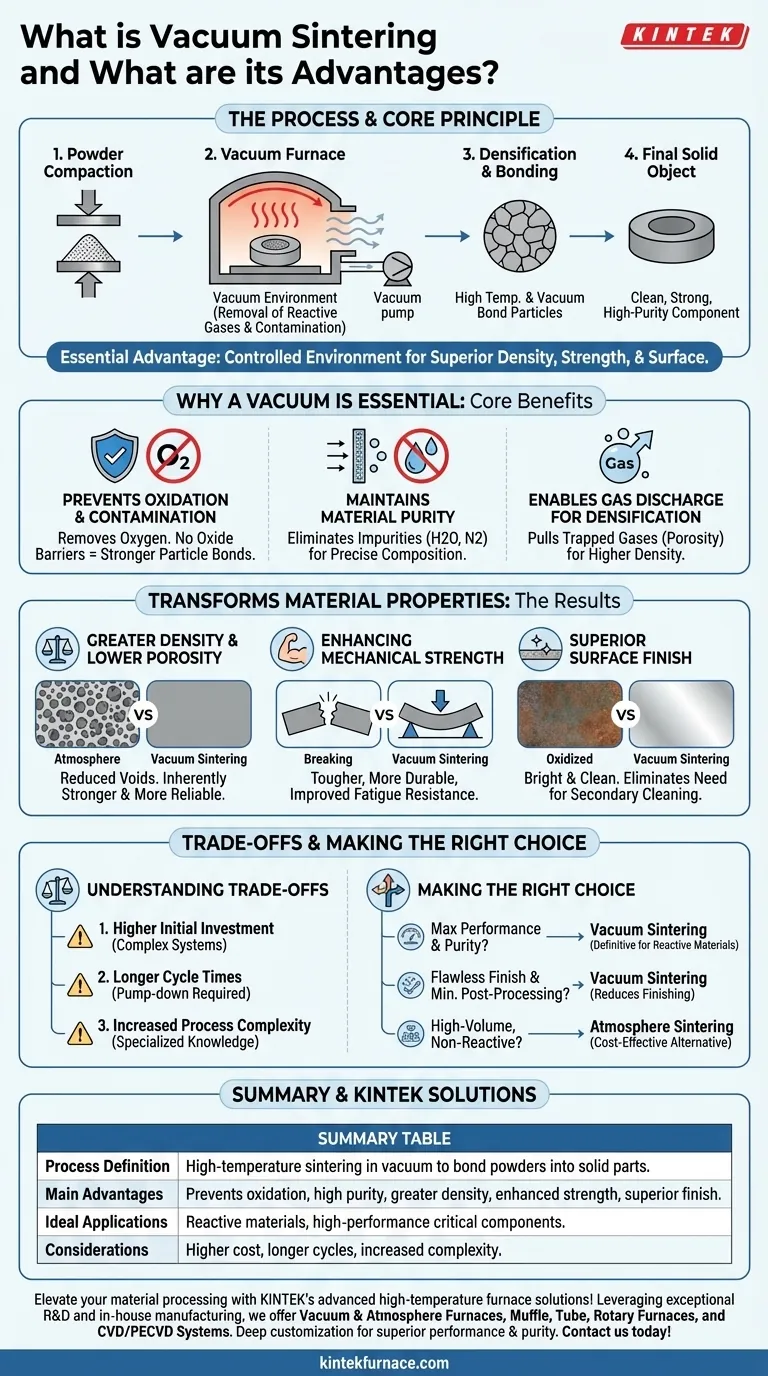

Vacuum sintering is a material processing technique that uses a high-temperature furnace under a vacuum to bond and densify powdered materials into a solid object. It is prized for creating exceptionally clean, strong, and high-purity components by preventing the oxidation and contamination that can occur in open-air or other atmospheric heating processes.

The essential advantage of vacuum sintering lies in its controlled environment. By removing reactive gases like oxygen, it allows for the formation of stronger bonds between material particles, resulting in a final part with superior density, strength, and surface quality.

The Core Principle: Why a Vacuum is Essential

The use of a vacuum is not incidental; it is the central element that delivers the process's key benefits. High temperatures accelerate chemical reactions, and the vacuum serves as a powerful shield.

Preventing Oxidation and Contamination

At sintering temperatures, most metals will readily react with oxygen in the air, forming oxides on the surface of the powder particles. These oxide layers act as a barrier, weakening the bonds between particles and compromising the integrity of the final part.

A vacuum removes virtually all oxygen, ensuring that the material surfaces remain perfectly clean, which allows for optimal metallurgical bonding.

Maintaining Material Purity

The vacuum environment also removes other potentially harmful atmospheric components, such as water vapor and nitrogen. This prevents unwanted chemical reactions that could introduce impurities or alter the material's intended composition, ensuring the final product meets strict material specifications.

Enabling Gas Discharge for Densification

During compaction, air can become trapped between powder particles. In the vacuum environment, these trapped gases are easily pulled out of the component as it heats up. This gas removal is critical for reducing internal voids (porosity), allowing the part to consolidate into a much denser final state.

How Vacuum Sintering Transforms Material Properties

The controlled environment directly translates into measurable improvements in the final component. These enhancements are the primary reason engineers and material scientists choose this process for demanding applications.

Achieving Greater Density and Lower Porosity

By facilitating the removal of trapped gases and preventing oxide formation, vacuum sintering produces parts with significantly higher density and near-zero porosity. A denser part is inherently stronger and more reliable under stress.

Enhancing Mechanical Strength

The combination of higher density and clean, strong bonds between material grains results in superior mechanical properties. Parts are tougher, more durable, and exhibit improved fatigue resistance compared to those sintered in atmosphere.

Delivering a Superior Surface Finish

Because no oxides form on the exterior of the part, components emerge from the furnace with a bright, smooth, and clean surface. This high-quality finish often eliminates the need for secondary cleaning or mechanical rework, saving both time and cost.

Understanding the Trade-offs

While powerful, vacuum sintering is not the universal solution for all applications. Understanding its limitations is key to making an informed decision.

Higher Initial Investment

Vacuum furnace systems are technologically complex and represent a greater capital investment compared to conventional atmospheric furnaces. This cost must be justified by the need for superior part quality.

Longer Cycle Times

The process of pumping the furnace down to the required vacuum level adds time to each production cycle. For very high-volume production of less demanding parts, this can be a limiting factor.

Increased Process Complexity

Operating a vacuum furnace requires specialized knowledge to manage vacuum levels, temperature profiles, and potential leak rates. It is a more technically demanding process than simple atmospheric heating.

Making the Right Choice for Your Application

Selecting the right sintering method depends entirely on the requirements of your final component and your manufacturing priorities.

- If your primary focus is maximum material performance and purity: Vacuum sintering is the definitive choice for reactive materials or when achieving the highest possible density and strength is critical.

- If your primary focus is a flawless surface finish and minimal post-processing: The bright, clean parts produced by vacuum sintering can significantly reduce or eliminate the need for secondary finishing operations.

- If your primary focus is high-volume production of non-reactive materials: Traditional atmospheric sintering may be a more cost-effective solution if the absolute highest material properties are not a strict requirement.

Ultimately, choosing vacuum sintering is a strategic decision to prioritize the ultimate quality and integrity of the final component.

Summary Table:

| Key Aspect | Details |

|---|---|

| Process Definition | High-temperature sintering in a vacuum to bond powdered materials into solid parts. |

| Main Advantages | Prevents oxidation, ensures high purity, achieves greater density, enhances mechanical strength, and provides superior surface finish. |

| Ideal Applications | Reactive materials, high-performance components where purity and strength are critical. |

| Considerations | Higher initial cost, longer cycle times, and increased process complexity. |

Elevate your material processing with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we offer a diverse product line including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements, delivering superior performance and purity for your components. Contact us today to discuss how our vacuum sintering furnaces can transform your production and achieve unparalleled results!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- What does the vacuum system of a vacuum furnace consist of? Essential Components for Clean Heat Processing

- What is a vacuum furnace and what processes can it perform? Unlock Precision Heat Treatment Solutions