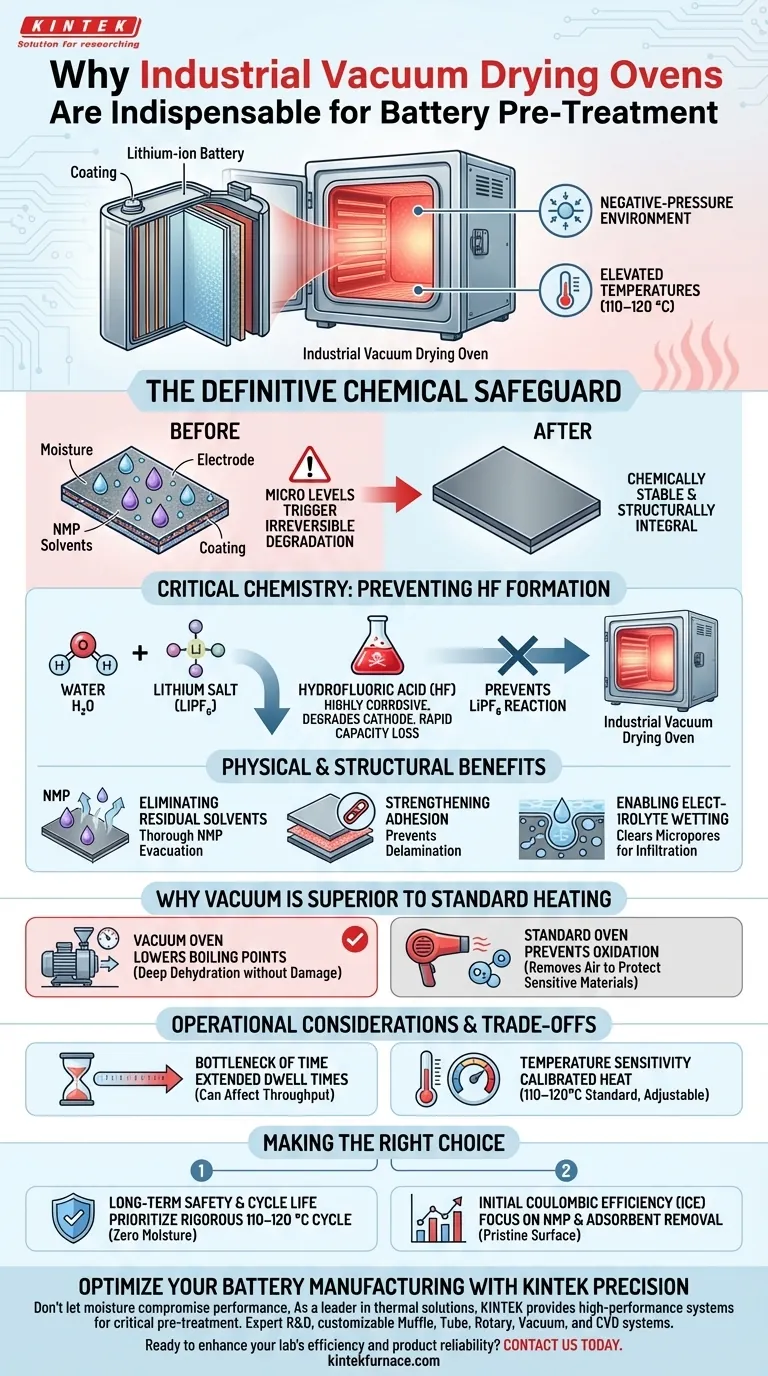

The industrial vacuum drying oven is the definitive safeguard against chemical corruption in battery manufacturing. Its primary function is to utilize a negative-pressure environment at elevated temperatures (typically 110–120 °C) to extract trace moisture and residual solvents like NMP from electrode sheets. This step is indispensable because even microscopic levels of retained water will trigger irreversible chemical degradation once the battery is sealed.

Core Takeaway: The vacuum drying oven is not merely a drying tool; it is a chemical stabilization device. By removing water molecules under vacuum, it prevents moisture from reacting with the electrolyte to produce hydrofluoric acid (HF). This ensures the structural integrity of the electrode and the long-term safety of the battery.

The Critical Chemistry: Preventing HF Formation

The Moisture-Electrolyte Reaction

Moisture is the greatest enemy of lithium-ion battery chemistry. When trace water molecules remain on the electrode, they react with lithium salts in the electrolyte, specifically LiPF6.

The Consequences of Acid Generation

This reaction produces hydrofluoric acid (HF), a highly corrosive byproduct. HF attacks the solid electrolyte interface (SEI) and degrades the cathode materials, leading to rapid capacity loss and potential safety hazards during battery cycling.

Physical and Structural Benefits

Eliminating Residual Solvents

Beyond moisture, the coating process leaves behind solvents such as N-methylpyrrolidone (NMP). The vacuum oven ensures these are thoroughly evacuated.

Strengthening Adhesion

Thorough removal of these volatile components strengthens the physical bond between the active material layer and the current collector. This prevents the electrode material from delaminating during the expansion and contraction cycles of battery use.

Enabling Electrolyte Wetting

Deep drying clears the micropores of the electrode materials. This porosity is essential for allowing the electrolyte to fully infiltrate (wet) the electrode arrays, which significantly reduces interfacial resistance and improves performance.

Why Vacuum is Superior to Standard Heating

Lowering Boiling Points

By operating under negative pressure, the oven lowers the boiling point of water and solvents. This allows for deep dehydration without requiring excessive temperatures that might damage the binder or active materials.

Preventing Oxidation

Standard ovens utilize hot air, which introduces oxygen to the material surface. Vacuum drying removes air from the chamber, preventing the oxidation of sensitive materials (such as fluoride or tin-based precursors) that can occur during conventional heating.

Operational Considerations and Trade-offs

The Bottleneck of Time

Deep dehydration is not instantaneous. To eliminate moisture trapped within the internal structure of the electrode, the process often requires extended dwell times, sometimes lasting overnight. This can create a throughput bottleneck in high-speed manufacturing lines.

Temperature Sensitivity

While 110–120 °C is a common standard, the temperature must be carefully calibrated. Some materials require lower temperatures (e.g., 80 °C) to prevent thermal degradation, while others require higher heat to ensure the purity of the final product.

Making the Right Choice for Your Goal

To maximize the effectiveness of your pre-treatment process, align your oven parameters with your specific performance targets:

- If your primary focus is long-term safety and cycle life: Prioritize a rigorous 110–120 °C cycle to ensure zero moisture remains to trigger HF production and electrolyte decomposition.

- If your primary focus is Initial Coulombic Efficiency (ICE): Focus on the thorough removal of NMP and physical adsorbents to ensure the electrode surface is pristine for optimal solid electrolyte interface (SEI) formation.

The industrial vacuum drying oven effectively transforms a coated electrode from a raw component into a chemically stable system ready for final assembly.

Summary Table:

| Feature | Benefit for Battery Manufacturing |

|---|---|

| Vacuum Environment | Lowers solvent boiling points & prevents oxidation of sensitive materials. |

| Moisture Removal | Prevents LiPF6 reaction and the formation of corrosive hydrofluoric acid (HF). |

| Solvent Evacuation | Thoroughly removes NMP to improve electrode adhesion and conductivity. |

| Enhanced Porosity | Clears micropores for superior electrolyte wetting and lower resistance. |

| Thermal Precision | Calibrated heat (110–120 °C) stabilizes chemicals without damaging binders. |

Optimize Your Battery Manufacturing with KINTEK Precision

Don't let moisture compromise your battery performance and safety. As a leader in laboratory and industrial thermal solutions, KINTEK provides the high-performance vacuum drying systems necessary for critical pre-treatment processes.

Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your specific temperature and throughput needs. Whether you are scaling up production or refining R&D, our engineering team ensures your electrodes are chemically stable and ready for assembly.

Ready to enhance your lab's efficiency and product reliability? Contact us today to discuss your custom high-temperature furnace requirements.

Visual Guide

References

- Behnoosh Bornamehr, Volker Presser. High-Performance Lithium-Ion Batteries with High Stability Derived from Titanium-Oxide- and Sulfur-Loaded Carbon Spherogels. DOI: 10.1021/acsami.3c16851

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is vacuum brazing and why is it important in modern manufacturing? Discover Superior, Clean Metal Joining

- What are the key benefits of vacuum brazing? Achieve Strong, Clean Joints for Complex Assemblies

- What are the advantages of using a vacuum carburizing furnace? Achieve Superior Quality and Efficiency

- How do argon and nitrogen protect samples in vacuum furnaces? Optimize Your Thermal Process with the Right Gas

- What is the principle behind microwave sintering furnaces? Discover Fast, Uniform Volumetric Heating

- Why is vacuum arc melting equipment used for TaC and TiC reinforced alloys? Achieving Purity and Thermal Precision

- What are the key indicators for measuring the performance of vacuum heat treatment equipment? Optimize Your Process with KINTEK

- What role does a reduction furnace play in the activation of CuO-Fe3O4 catalysts? Master Catalyst Engineering