In short, the primary advantages of a vacuum carburizing furnace are superior part quality, faster processing times, and a highly controlled, clean operating environment. This technology eliminates surface oxidation common in traditional methods, resulting in components with significantly improved mechanical properties and dimensional stability right out of the furnace.

Vacuum carburizing shifts heat treatment from a brute-force process to a precise, scientific one. Its core advantage lies in using a vacuum to create a perfectly clean slate, allowing for the exact and uniform infusion of carbon, which fundamentally enhances the final component's performance and consistency.

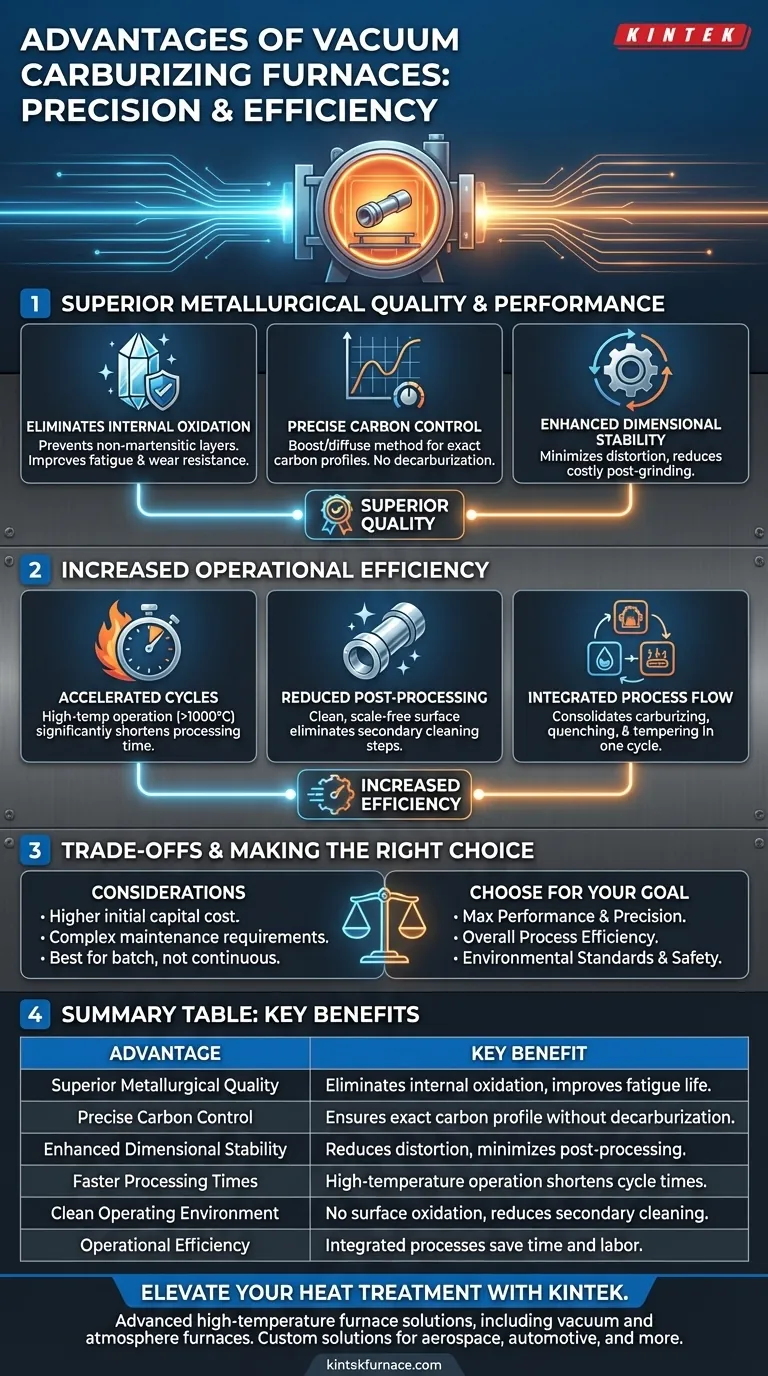

Superior Metallurgical Quality and Performance

The most significant benefit of vacuum carburizing is the dramatic improvement in the metallurgical quality of the treated component. This is achieved through an exceptionally clean and controlled processing environment.

Elimination of Internal Oxidation

In traditional atmosphere carburizing, oxygen is present and reacts with alloying elements in the steel (like chromium and manganese), creating an undesirable, non-martensitic layer at the surface. A vacuum furnace removes virtually all oxygen before the process begins, completely preventing this internal oxidation. This results in a cleaner microstructure, which directly improves the fatigue life and wear resistance of the part.

Precise Carbon Control

Vacuum carburizing uses a "boost/diffuse" method. A hydrocarbon gas (like propane or acetylene) is introduced in pulses (boost), followed by a period where the gas is cut off and the furnace is evacuated to allow the carbon to diffuse uniformly into the steel (diffuse). This process gives engineers unparalleled control over the final carbon profile, ensuring the surface has the exact carbon content desired without the risk of decarburization.

Enhanced Dimensional Stability

The combination of precise temperature management and a uniform heating and cooling environment significantly reduces part distortion. This preservation of dimensional stability is critical for high-precision components like gears, bearings, and injection molding tools, as it minimizes the need for costly and time-consuming post-heat-treat grinding.

Increased Operational Efficiency

Beyond part quality, vacuum carburizing offers tangible benefits to the manufacturing workflow, improving speed and reducing downstream labor.

Accelerated Carburizing Cycles

Because the process is free from the risk of oxidation, vacuum carburizing can be performed at much higher temperatures—often exceeding 1000°C (1832°F). This high-temperature capability significantly shortens the carburizing cycle time, increasing throughput compared to conventional methods that are limited to lower temperatures.

Reduced Post-Processing Requirements

Parts emerge from a vacuum furnace with a clean, bright, and scale-free surface. This often eliminates the need for secondary cleaning operations like shot blasting or chemical stripping, saving both time and money in the production chain.

Integrated Process Flow

Modern vacuum carburizing furnaces are often multi-functional systems. A single unit can perform low-pressure carburizing, quenching (using either high-pressure gas or oil), and tempering, consolidating multiple process steps into one automated cycle.

Understanding the Trade-offs

While powerful, vacuum carburizing is not a universal solution. Acknowledging its specific requirements is crucial for a balanced assessment.

Higher Initial Capital Investment

Vacuum furnace technology is more sophisticated than traditional atmosphere furnaces. This results in a higher upfront equipment cost, which must be weighed against the long-term gains in quality, efficiency, and reduced post-processing.

Maintenance and Operational Complexity

Maintaining the integrity of the vacuum system—including pumps, seals, and control systems—requires specialized knowledge and diligent maintenance protocols. The process requires skilled operators who understand the nuances of vacuum technology and process control.

Suitability for Batch Processing

Vacuum carburizing is fundamentally a batch process. While highly efficient for high-value components, it may not be the most cost-effective solution for extremely high-volume, low-mix production where continuous furnaces might offer a better economy of scale.

Making the Right Choice for Your Goal

Selecting the right carburizing method depends entirely on your specific manufacturing priorities and component requirements.

- If your primary focus is maximum part performance and precision: The elimination of internal oxidation and superior dimensional control make vacuum carburizing the ideal choice for critical applications like aerospace or high-performance gearing.

- If your primary focus is overall process efficiency: The combination of faster cycle times at high temperatures and the reduction or elimination of post-process cleaning provides a compelling case for improving throughput and lowering total part cost.

- If your primary focus is environmental standards and safety: The clean, contained process with no endothermic gas generators or open flames makes vacuum carburizing a definitive step toward a safer and more environmentally friendly operation.

Ultimately, adopting vacuum carburizing is an investment in control, consistency, and a higher standard of quality for your most demanding components.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Superior Metallurgical Quality | Eliminates internal oxidation, improves fatigue life and wear resistance |

| Precise Carbon Control | Ensures exact carbon profile without decarburization |

| Enhanced Dimensional Stability | Reduces distortion, minimizes post-processing |

| Faster Processing Times | High-temperature operation shortens cycle times |

| Clean Operating Environment | No surface oxidation, reduces secondary cleaning |

| Operational Efficiency | Integrated processes save time and labor |

Ready to elevate your heat treatment processes with precision and efficiency? KINTEK specializes in advanced high-temperature furnace solutions, including vacuum and atmosphere furnaces, tailored to meet your unique needs. Our expertise in R&D and in-house manufacturing ensures reliable performance for industries like aerospace and automotive. Contact us today to discuss how our custom solutions can enhance your component quality and operational workflow!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- Where are vacuum furnaces used? Critical Applications in Aerospace, Medical, and Electronics

- What is the heat treatment in a vacuum furnace? Achieve Superior Metallurgical Properties

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing