At its core, vacuum brazing is a high-temperature joining process where a filler metal is used to fuse two or more components together inside a vacuum furnace. The vacuum environment is the critical factor, as it prevents the formation of oxides and eliminates the need for corrosive chemical fluxes. This results in exceptionally clean, strong, and leak-proof joints, making it a cornerstone technique for manufacturing high-performance parts.

Vacuum brazing is more than a simple joining method; it is a controlled metallurgical process. By removing the atmosphere, it enables the creation of superior, contamination-free bonds in complex assemblies and advanced materials that are otherwise difficult or impossible to join reliably.

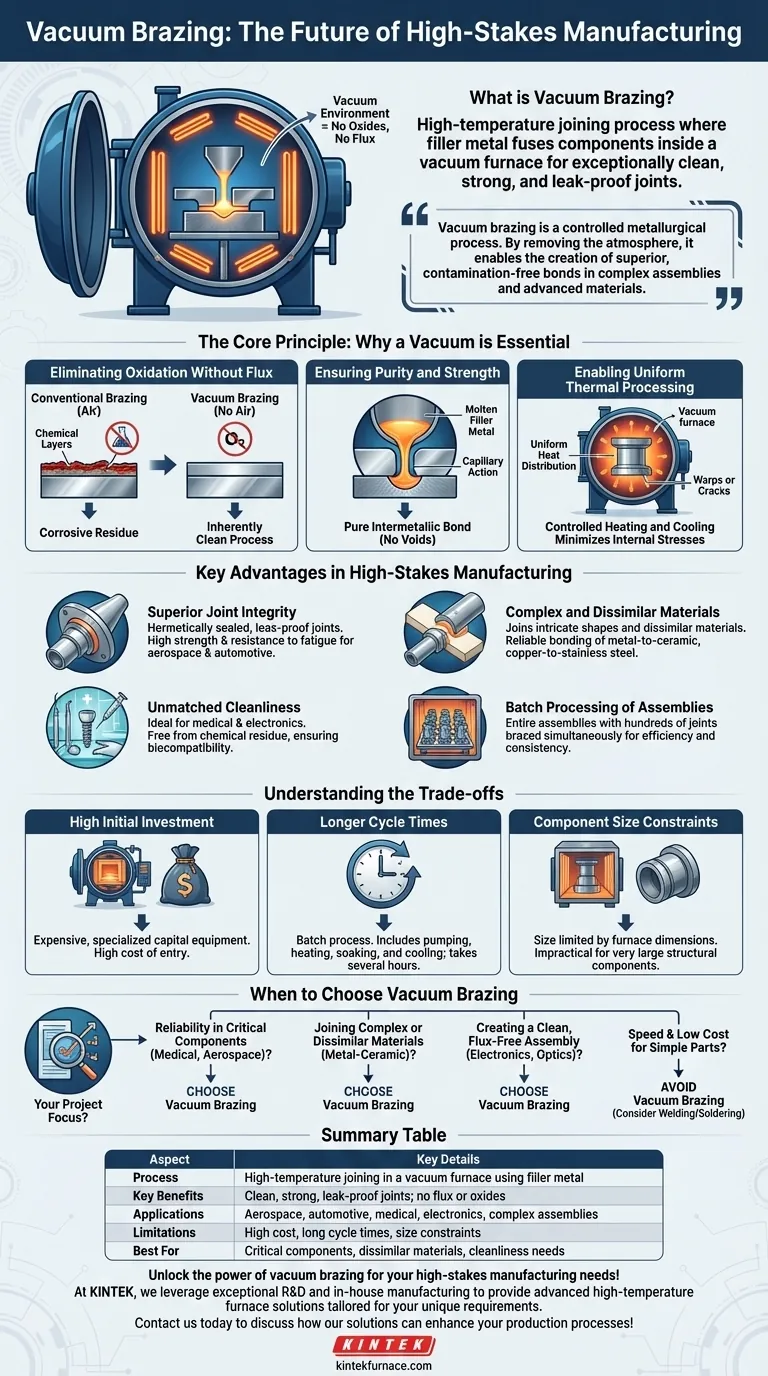

The Core Principle: Why a Vacuum is Essential

The importance of vacuum brazing lies not in the heat, but in the environment. The vacuum itself is the enabling technology that provides a level of control unattainable with other high-temperature joining methods.

Eliminating Oxidation Without Flux

All conventional brazing and welding processes must contend with oxygen in the air. At high temperatures, oxygen rapidly forms brittle oxide layers on the metal surfaces, preventing a strong bond.

Traditional methods solve this by using a chemical flux, which cleans the surfaces but leaves behind a corrosive residue that must be thoroughly removed.

Vacuum brazing solves the problem at its source. By removing the air from the furnace, there is virtually no oxygen to create oxides in the first place. This results in an inherently clean process.

Ensuring Purity and Strength

Because no oxides or flux residues are present, the molten filler metal can wet the parent materials perfectly. It flows cleanly into the joint via capillary action.

Upon cooling, this creates a pure, robust intermetallic bond between the filler and the base materials. The resulting joint is free of voids and contaminants, leading to exceptional strength and ductility.

Enabling Uniform Thermal Processing

A vacuum furnace heats components with extreme uniformity. This controlled heating and slow, even cooling cycle minimizes internal stresses and distortion in the final assembly.

This is critical for complex geometries or delicate parts that would warp or crack under the localized, intense heat of a welding torch. The entire component is strengthened, not just the joint.

Key Advantages in High-Stakes Manufacturing

The controlled, clean environment of vacuum brazing delivers tangible benefits that are essential in modern, high-tech industries.

Superior Joint Integrity

Vacuum brazed joints are hermetically sealed and leak-proof, making them ideal for systems that handle vacuums, high pressures, or sensitive fluids. Their high strength and resistance to fatigue are critical for aerospace and automotive applications.

Complex and Dissimilar Materials

The process excels at joining intricate shapes and, crucially, dissimilar materials. It is one of the few reliable methods for bonding metals to ceramics or joining metals with vastly different properties, such as copper to stainless steel.

Unmatched Cleanliness

For the medical and electronics industries, cleanliness is not optional. Vacuum brazing produces components—like surgical instruments, implants, and vacuum tubes—that are free from any chemical residue, ensuring biocompatibility and reliable performance.

Batch Processing of Assemblies

An entire assembly with dozens or even hundreds of joints can be brazed simultaneously in a single furnace cycle. This is far more efficient and consistent than joining each point individually.

Understanding the Trade-offs

While powerful, vacuum brazing is not a universal solution. Its advantages come with specific limitations that make it unsuitable for certain applications.

High Initial Investment

Vacuum furnaces are highly specialized and expensive pieces of capital equipment. The cost of entry is significant compared to standard welding or soldering setups.

Longer Cycle Times

The process is inherently a batch process. A full cycle involves pumping the vacuum, ramping up the temperature, holding (soaking) at the brazing point, and slowly cooling. This can take several hours, making it slower than continuous or instantaneous joining methods.

Component Size Constraints

The size of the parts you can braze is strictly limited by the internal dimensions of the vacuum furnace chamber. This makes it impractical for very large structural components.

When to Choose Vacuum Brazing

Your choice of joining method must align with the demands of your project. Use these guidelines to determine if vacuum brazing is the right approach.

- If your primary focus is reliability in critical components: Vacuum brazing is the standard for medical implants, aerospace engine parts, and scientific instruments where joint failure is not an option.

- If your primary focus is joining complex or dissimilar materials: This process is one of the few that can reliably create strong bonds between materials like metal and ceramic or reactive metals like titanium.

- If your primary focus is creating a clean, flux-free assembly: For electronics, optics, or food-grade equipment, the inherent cleanliness of vacuum brazing prevents contamination.

- If your primary focus is speed and low cost for simple parts: Vacuum brazing is likely overkill; conventional welding, soldering, or mechanical fastening are far more economical and faster.

Ultimately, understanding vacuum brazing is understanding how to achieve metallurgical perfection in a controlled environment.

Summary Table:

| Aspect | Key Details |

|---|---|

| Process | High-temperature joining in a vacuum furnace using filler metal |

| Key Benefits | Clean, strong, leak-proof joints; no flux or oxides |

| Applications | Aerospace, automotive, medical, electronics, complex assemblies |

| Limitations | High cost, long cycle times, size constraints |

| Best For | Critical components, dissimilar materials, cleanliness needs |

Unlock the power of vacuum brazing for your high-stakes manufacturing needs! At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for your unique requirements. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is designed to deliver precise, reliable performance with strong deep customization capabilities. Whether you're in aerospace, medical, or electronics, we can help you achieve superior joint integrity and efficiency. Contact us today to discuss how our solutions can enhance your production processes!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is a vacuum furnace and what processes can it perform? Unlock Precision Heat Treatment Solutions

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- What does the vacuum system of a vacuum furnace consist of? Essential Components for Clean Heat Processing

- Why should nitrogen not be used as a cooling gas for titanium alloys in vacuum heat treatment? Avoid Catastrophic Failures

- How does a vacuum heat treatment furnace prevent contamination? Ensure Purity in High-Temperature Processes