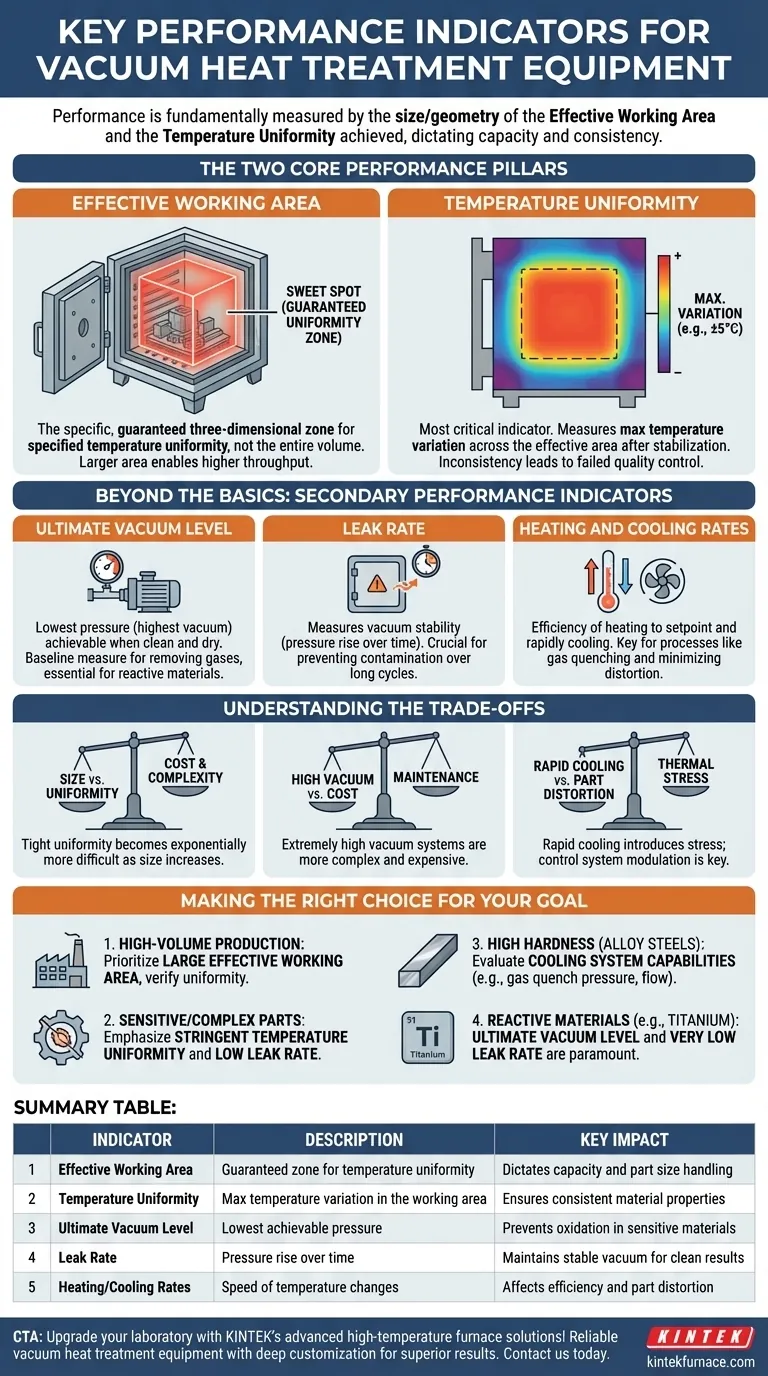

The performance of vacuum heat treatment equipment is fundamentally measured by two primary indicators: the size and geometry of its effective working area and the temperature uniformity achieved within that space. These factors directly dictate the equipment's capacity and, more importantly, its ability to produce consistent, high-quality results for the parts being treated.

While manufacturers often highlight specifications like maximum temperature or pump speed, the true measure of a vacuum furnace is its ability to deliver a predictable and repeatable thermal process. This is defined by how uniformly it can apply temperature to your parts within a stable, controlled vacuum environment.

The Two Core Performance Pillars

The quality of any vacuum heat treatment process—from simple annealing to complex gas quenching—depends almost entirely on two core characteristics of the furnace. These are the metrics that have the most direct impact on the final properties of the material.

Defining the Effective Working Area

The effective working area is not the entire internal volume of the furnace. It is the specific, guaranteed three-dimensional zone where the equipment can maintain the specified temperature uniformity.

Think of it as the "sweet spot." Parts placed outside this zone will not experience the same controlled thermal cycle, leading to inconsistent results, failed quality control, and scrapped material. A larger effective area allows for higher throughput or the processing of larger single components.

The Critical Role of Temperature Uniformity

Temperature uniformity is arguably the most critical performance indicator. It measures the maximum temperature variation (e.g., ±5°C or ±10°F) across the entire effective working area once the furnace has stabilized at its setpoint temperature.

Poor uniformity means different parts of a single component, or different components in a batch, are being treated at different temperatures. This leads directly to inconsistent hardness, grain structure, and potential distortion, completely undermining the goal of the heat treatment process.

Beyond the Basics: Secondary Performance Indicators

While the working area and temperature uniformity define the quality of the thermal process, other indicators define the quality of the vacuum environment and the efficiency of the operation.

Ultimate Vacuum Level

This is the lowest pressure (highest vacuum) the furnace's pumping system can achieve when the chamber is clean, empty, and dry. It indicates the system's theoretical capability to remove atmospheric gases.

A lower ultimate vacuum is essential for processing highly reactive materials that are sensitive to oxidation. It is a baseline measure of the pumping system's health and design, which often includes a series of pumps like a backing pump and a high-vacuum diffusion pump.

Leak Rate

In practice, the leak rate is often more important than the ultimate vacuum for day-to-day operations. It measures how well the furnace chamber maintains its vacuum, typically expressed as pressure rise over time (e.g., microns per hour).

A low leak rate ensures that the controlled vacuum environment is stable throughout the long heating cycle, preventing contamination from microscopic leaks in seals, welds, or fittings. This is crucial for achieving clean, bright surfaces and avoiding undesirable reactions.

Heating and Cooling Rates

The efficiency and capability of a furnace are also measured by how quickly it can heat a workload to the setpoint temperature and, critically, how quickly it can cool it.

For processes like vacuum gas quenching, the cooling rate is a key performance metric. A high-pressure gas quench system's ability to extract heat rapidly is what allows for the hardening of many types of steel without the use of oil or water, resulting in less distortion and a cleaner final product.

Understanding the Trade-offs

Selecting or evaluating vacuum heat treatment equipment involves balancing competing priorities. Understanding these trade-offs is key to making an informed decision.

Size vs. Uniformity

Achieving tight temperature uniformity becomes exponentially more difficult and expensive as the size of the effective working area increases. A very large furnace with poor uniformity is less useful than a smaller furnace that delivers a perfectly consistent process.

High Vacuum vs. Cost

Systems designed for extremely high vacuum levels are more complex, require more maintenance, and have a higher initial cost. It is essential to match the vacuum requirements of your material to the equipment's capability, as over-specifying the vacuum level adds unnecessary expense.

Rapid Cooling vs. Part Distortion

While rapid cooling is a key advantage of modern vacuum furnaces, it can also introduce significant thermal stress, leading to distortion or even cracking in parts with complex geometries. A high-performance system is not just about raw cooling power, but also about the control system's ability to modulate and program the cooling cycle to match the part's needs.

Making the Right Choice for Your Goal

Your specific application determines which performance indicators should be prioritized.

- If your primary focus is high-volume production: Prioritize a large effective working area, but verify that the certified temperature uniformity is met across that entire zone.

- If your primary focus is processing sensitive or complex parts: Emphasize stringent temperature uniformity (e.g., ±5°C or better) and a certified low leak rate to ensure process stability.

- If your primary focus is achieving high hardness in alloy steels: Evaluate the cooling system's capabilities, such as maximum gas quench pressure (e.g., 2 to 20 bar) and gas flow dynamics.

- If your primary focus is working with highly reactive materials (e.g., titanium): The ultimate vacuum level and a very low leak rate become paramount to prevent any oxidation or surface contamination.

By focusing on these core performance indicators, you can move beyond marketing specifications and select a system that delivers reliable and repeatable results for your specific application.

Summary Table:

| Indicator | Description | Key Impact |

|---|---|---|

| Effective Working Area | Guaranteed zone for temperature uniformity | Dictates capacity and part size handling |

| Temperature Uniformity | Max temperature variation in the working area | Ensures consistent material properties |

| Ultimate Vacuum Level | Lowest achievable pressure | Prevents oxidation in sensitive materials |

| Leak Rate | Pressure rise over time | Maintains stable vacuum for clean results |

| Heating/Cooling Rates | Speed of temperature changes | Affects efficiency and part distortion |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable vacuum heat treatment equipment, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, delivering superior temperature control, uniform heating, and efficient performance. Contact us today to discuss how we can enhance your process reliability and results!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion