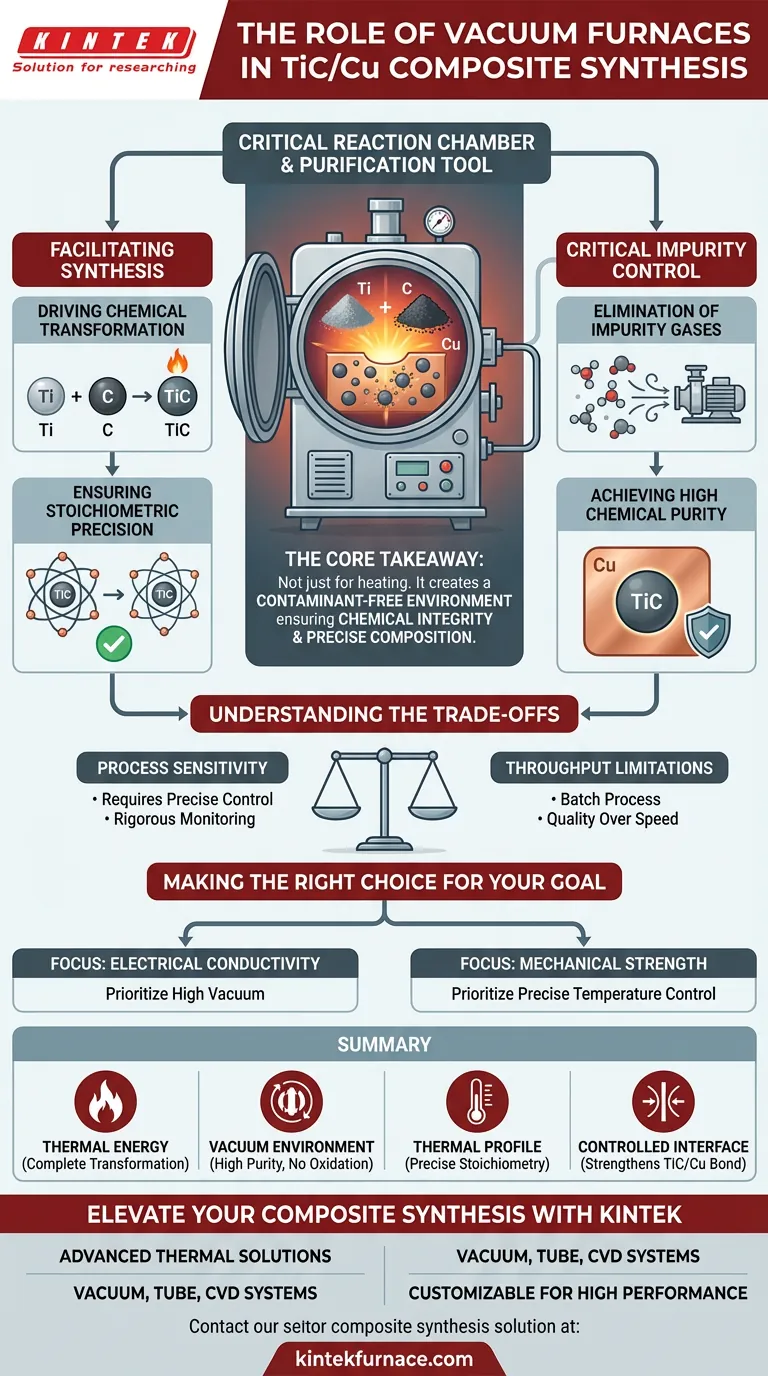

The vacuum furnace serves as the critical reaction chamber for the solid-phase synthesis of Titanium Carbide (TiC) within Copper (Cu) composite materials.

It provides a strictly controlled, high-temperature environment that drives the chemical reaction between titanium and carbon powders. By operating under a vacuum, the furnace simultaneously eliminates impurity gases, ensuring the resulting TiC particles achieve the necessary chemical purity and precise stoichiometric ratio required for high-performance composites.

The Core Takeaway The vacuum furnace does more than simply heat materials; it acts as a purification tool. Its primary value lies in creating a contaminant-free environment that ensures the chemical integrity and precise composition of the TiC reinforcement particles.

Facilitating the Synthesis Reaction

Driving the Chemical Transformation

The fundamental role of the vacuum furnace is to supply the thermal energy required to trigger the reaction between solid titanium and carbon powders.

This high-temperature environment overcomes the activation energy barrier, allowing the precursors to react chemically. The result is the generation of stable Titanium Carbide (TiC) particles.

Ensuring Stoichiometric Precision

In material synthesis, the ratio of elements (stoichiometry) dictates the material's final properties.

The vacuum furnace provides a stable thermal profile that facilitates a complete and uniform reaction. This ensures the synthesized TiC possesses a favorable stoichiometric ratio, preventing the formation of unstable or unwanted phases.

The Critical Role of Impurity Control

Elimination of Impurity Gases

One of the most distinct advantages of using a vacuum furnace over standard atmospheric furnaces is the removal of volatiles.

During the heating process, the vacuum environment actively extracts impurity gases released by the powders or present in the chamber. This prevents oxidation and other atmospheric contamination that could degrade the composite.

Achieving High Chemical Purity

The mechanical performance of a TiC/Cu composite depends heavily on the purity of the reinforcing TiC particles.

By eliminating gaseous contaminants, the vacuum furnace ensures the synthesized TiC particles maintain high chemical purity. This leads to a cleaner interface between the TiC reinforcement and the Copper matrix.

Understanding the Trade-offs

Process Sensitivity

While the vacuum furnace offers superior purity, it requires precise control over vacuum levels and heating rates.

Deviations in the vacuum pressure or temperature profile can lead to incomplete reactions or deviations in stoichiometry. The equipment demands rigorous monitoring compared to simpler atmospheric furnaces.

Throughput Limitations

Vacuum synthesis is generally a batch process involving pump-down and cool-down cycles.

This often results in lower production throughput compared to continuous processing methods, making it a choice that prioritizes quality over speed.

Making the Right Choice for Your Goal

To maximize the effectiveness of a vacuum furnace in TiC/Cu synthesis, align your process parameters with your specific material requirements:

- If your primary focus is electrical conductivity: Prioritize high vacuum levels to eliminate impurities that could scatter electrons at the TiC/Cu interface.

- If your primary focus is mechanical strength: Focus on precise temperature control to ensure the ideal stoichiometric ratio, which maximizes the hardness of the TiC particles.

The vacuum furnace is the defining instrument for converting raw powders into high-grade engineering materials through strictly controlled purification and reaction.

Summary Table:

| Feature | Role in TiC/Cu Synthesis | Impact on Final Composite |

|---|---|---|

| Thermal Energy | Overcomes activation energy barrier | Ensures complete chemical transformation to TiC |

| Vacuum Environment | Active extraction of impurity gases | Prevents oxidation and ensures high chemical purity |

| Thermal Profile | Provides stable, uniform heating | Achieves precise stoichiometric ratios for hardness |

| Controlled Interface | Eliminates atmospheric contaminants | Strengthens the bond between TiC and Copper matrix |

Elevate Your Composite Synthesis with KINTEK

Precision in TiC/Cu synthesis requires more than just heat; it demands the absolute control provided by KINTEK’s advanced thermal solutions. Backed by expert R&D and world-class manufacturing, we offer specialized Vacuum, Tube, and CVD systems tailored for the rigorous demands of solid-phase synthesis.

Whether you need to maximize electrical conductivity or mechanical strength, our customizable high-temperature furnaces ensure the chemical integrity your lab requires. Contact KINTEK today to discuss your unique project needs and discover how our expert-engineered systems can optimize your material performance.

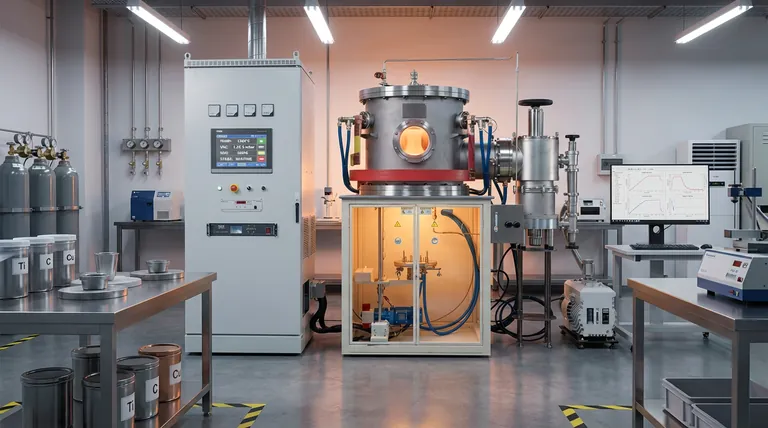

Visual Guide

References

- Zhenjie Zhai, Cong Chen. Effect of TiC Particles on the Properties of Copper Matrix Composites. DOI: 10.3390/inorganics12040120

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What critical conditions does a vacuum sintering furnace provide for cemented carbides? Ensuring Peak Material Density

- What are the advantages of vacuum furnaces? Achieve Pristine Material Processing and Control

- Why is oxidation a concern when heating metals, and how does a vacuum furnace address this? Ensure Purity and Performance

- What are the advantages of using a vacuum heat treatment furnace? Precision Solution Treatment for 17-4PH Steel

- How are vacuum furnaces used in the preparation of special alloys? Unlock Purity and Performance

- How do drop-bottom quench furnaces compare to other furnace types? Discover Their Speed and Precision Advantages

- What are the primary functions of a vacuum furnace? Achieve Superior Material Processing in a Controlled Environment

- What are the key differences in maximum temperature between low vacuum and high vacuum furnaces? Unlock Higher Heat for Purity