In essence, vacuum furnaces create an ultra-pure, high-temperature environment that is free of reactive gases like oxygen and nitrogen. This control is critical for preparing special alloys, as it prevents the formation of unwanted oxides and impurities that would otherwise compromise the material's unique chemical composition, structural integrity, and performance characteristics.

The fundamental advantage of a vacuum furnace is not just the heat it provides, but the pristine environment it creates. By removing the atmosphere, it allows for the melting, sintering, and heat treatment of highly reactive metals to form alloys with properties that would be impossible to achieve otherwise.

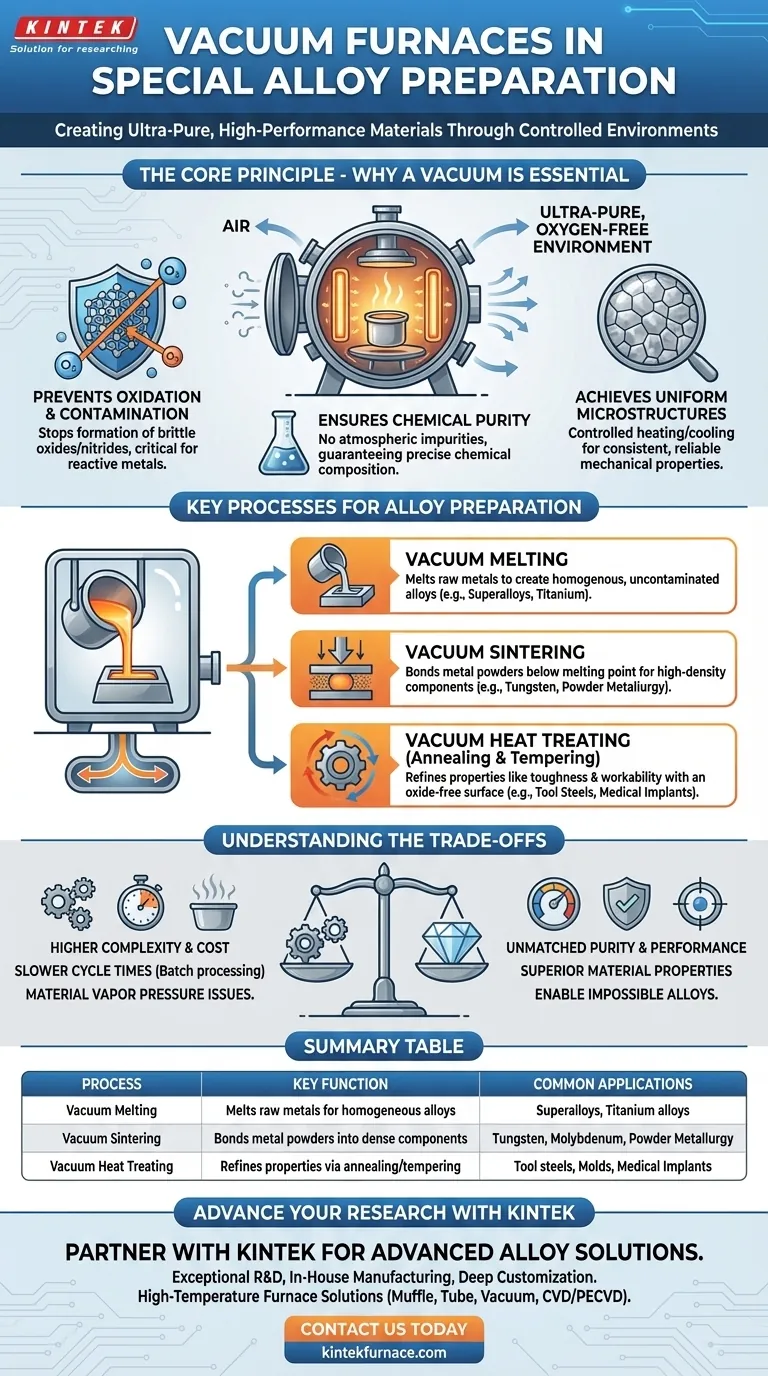

The Core Principle: Why a Vacuum is Essential

At the extreme temperatures required for alloy preparation, most metals become highly reactive. Introducing a vacuum is the key to controlling this reactivity and ensuring the final product meets precise specifications.

Preventing Oxidation and Contamination

When heated, metals readily react with oxygen and other gases in the air. This process, oxidation, forms a brittle, impure layer on the material.

A vacuum environment removes these reactive gases. This prevents the formation of oxides and nitrides, which act as contaminants and degrade the mechanical properties of the alloy. This is especially crucial for reactive materials like titanium and superalloys.

Ensuring Chemical Purity

Special alloys are defined by their precise chemical recipes. Even minor contamination can drastically alter their intended properties, such as strength, corrosion resistance, or heat tolerance.

By operating in a vacuum, furnaces ensure that no unintended elements from the atmosphere are introduced during melting or heating. This guarantees the final alloy has the exact chemical composition required for its high-performance application.

Achieving Uniform Microstructures

The controlled heating and cooling cycles within a vacuum furnace promote the formation of uniform grain structures.

This consistency throughout the material is vital for predictable and reliable mechanical properties. It eliminates weak points that can lead to premature failure in demanding environments like jet engines or medical implants.

Key Processes for Alloy Preparation

Vacuum furnaces are not a single-use tool; they are versatile platforms that enable several distinct manufacturing processes.

Vacuum Melting

This is the foundational process for creating an alloy from its constituent raw metals. The materials are heated to a liquid state inside the vacuum.

This process ensures the elements mix completely into a homogenous liquid without contamination before being cast into a solid shape, known as an ingot. It is the standard for producing superalloys and titanium alloys.

Vacuum Sintering

Sintering is used for materials with extremely high melting points, such as tungsten and molybdenum, and in powder metallurgy.

Instead of melting, fine metal powders are heated to a high temperature below their melting point. The heat and pressure cause the powder particles to bond and fuse, forming a dense, solid component with a uniform internal structure.

Vacuum Heat Treating (Annealing & Tempering)

Heat treating is a secondary process performed on an already-formed alloy to refine its properties.

Annealing involves heating and slow cooling to refine the grain structure, making the material more workable. Tempering is done after hardening to reduce internal stresses and increase toughness. Performing these treatments in a vacuum ensures an oxide-free surface, which is critical for finished components like tool steels and molds.

Understanding the Trade-offs

While indispensable, vacuum furnace technology involves clear trade-offs that are important to understand.

High Operational Complexity

Vacuum furnaces are sophisticated systems. Achieving and maintaining a high vacuum requires complex pumping systems, seals, and instrumentation, leading to higher initial costs and maintenance requirements compared to atmospheric furnaces.

Slower Cycle Times

The process of pumping down the chamber to the required vacuum level takes time. This means vacuum furnaces typically operate in batches, which can result in lower throughput compared to continuous, open-atmosphere processes.

Material Vapor Pressure

In a deep vacuum, some elements with a high vapor pressure can begin to "boil off" or outgas from the molten alloy at high temperatures. This phenomenon can slightly alter the final chemical composition and must be carefully managed.

Making the Right Choice for Your Goal

The specific vacuum process you use depends entirely on your material and desired outcome.

- If your primary focus is to create a new, high-purity alloy from raw elements: Vacuum melting is the essential first step to ensure a homogenous and uncontaminated mixture.

- If your primary focus is to form a component from difficult-to-melt metal powders: Vacuum sintering is the correct process for materials like tungsten or specialized hard metals.

- If your primary focus is to refine the properties of an existing alloy: Vacuum heat treating (annealing or tempering) is used to optimize strength, toughness, and durability without surface damage.

Ultimately, mastering vacuum furnace technology is fundamental to engineering the advanced materials that define modern high-performance industries.

Summary Table:

| Process | Key Function | Common Applications |

|---|---|---|

| Vacuum Melting | Melts raw metals in vacuum to create homogeneous alloys | Superalloys, titanium alloys |

| Vacuum Sintering | Bonds metal powders without melting for dense components | Tungsten, molybdenum, powder metallurgy |

| Vacuum Heat Treating | Refines properties via annealing/tempering in vacuum | Tool steels, molds, medical implants |

Need advanced vacuum furnace solutions for your alloy preparation? KINTEK leverages exceptional R&D and in-house manufacturing to provide diverse laboratories with high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements. Contact us today to enhance your material performance and efficiency!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control

- What is a vacuum furnace and what processes can it perform? Unlock Precision Heat Treatment Solutions

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing

- How does a vacuum heat treatment furnace prevent contamination? Ensure Purity in High-Temperature Processes