In the landscape of industrial heat treatment, drop-bottom quench furnaces distinguish themselves through their exceptional speed and precision, particularly for processes requiring rapid quenching. They uniquely combine the processing flexibility of a batch furnace with the high-performance quenching capabilities needed for developing superior material properties in sensitive alloys, setting them apart from both continuous systems and standard batch furnaces.

Choosing the right furnace is not just about reaching a target temperature; it's about controlling the entire thermal cycle. The primary advantage of a drop-bottom furnace is its ability to minimize the time between heating and quenching, which is critical for achieving maximum hardness and preventing distortion.

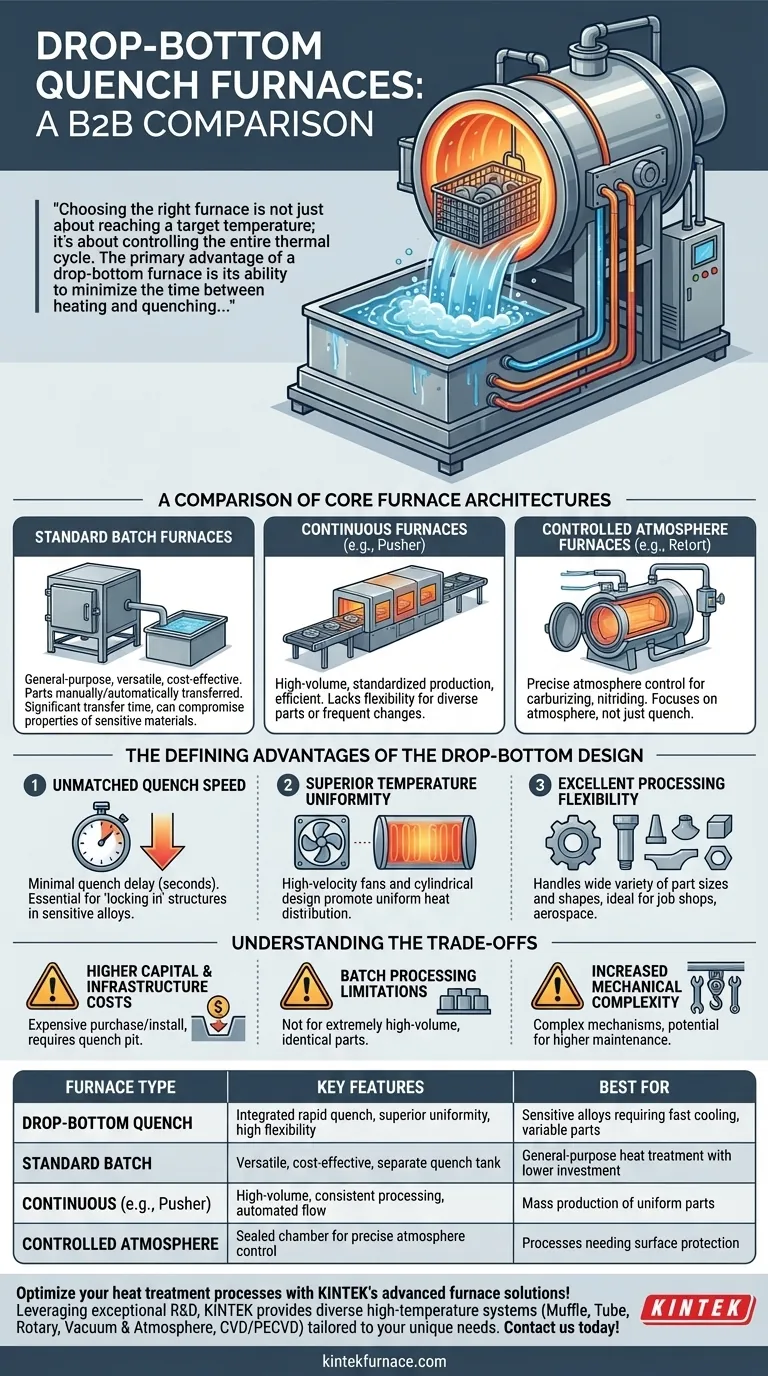

A Comparison of Core Furnace Architectures

To understand the value of a drop-bottom furnace, it is essential to first understand the alternatives. Each furnace type is designed to solve a different set of production and metallurgical challenges.

Standard Batch Furnaces

These are the general-purpose workhorses of heat treatment, often configured as a simple box or chamber. Parts are loaded, heated, and then manually or automatically transferred to a separate, external quench tank.

While versatile and cost-effective, the transfer time from furnace to quench can be significant. This delay can compromise the final properties of materials that require an extremely rapid cool-down.

Continuous Furnaces (e.g., Pusher)

Continuous furnaces are designed for high-volume, standardized production. Parts are continuously fed through different heating and cooling zones on a conveyor or are "pushed" through the furnace in trays.

Their strength is efficiency and consistency for a single, repeatable process. However, they lack the flexibility to handle diverse component sizes or frequent changes in treatment cycles.

Controlled Atmosphere Furnaces (e.g., Retort)

The defining feature of a retort furnace is its sealed inner chamber, which allows for precise control of the furnace atmosphere. This is critical for processes like carburizing, nitriding, or bright annealing where reactions with air must be prevented.

While a drop-bottom furnace can also have a controlled atmosphere, its primary design advantage is its quench mechanism, not just the atmosphere control itself.

The Defining Advantages of the Drop-Bottom Design

A drop-bottom furnace is a specialized type of batch furnace that integrates the quench tank directly beneath the heating chamber. This architecture delivers several key benefits.

Unmatched Quench Speed

This is the most significant advantage. Once the parts are at temperature, the entire bottom of the furnace opens, dropping the load directly into the quench tank below. This transfer often takes only a few seconds.

This minimal quench delay is crucial for aluminum alloys, superalloys, and certain steels, as it allows for the "locking in" of desired metallurgical structures that produce maximum strength and hardness.

Superior Temperature Uniformity

Drop-bottom furnaces are typically cylindrical and use high-velocity fans to circulate the internal atmosphere. This design promotes exceptionally uniform heat distribution throughout the entire workload.

This uniformity ensures that all parts, regardless of their position in the basket, achieve the same properties, reducing variability and improving overall quality.

Excellent Processing Flexibility

Like other batch furnaces, drop-bottoms can handle a wide variety of part sizes and shapes, including large, complex, or long components that are difficult to manage in a continuous system.

This makes them ideal for job shops or aerospace and defense applications where production runs are smaller and part geometry varies significantly.

Understanding the Trade-offs

No single solution is perfect for every application. The unique design of a drop-bottom furnace comes with specific considerations that must be weighed.

Higher Capital and Infrastructure Costs

The mechanical systems for the "drop" mechanism and the required infrastructure—namely, a pit excavated beneath the furnace for the quench tank—make these units more expensive to purchase and install than a standard box furnace.

Batch Processing Limitations

While flexible, it is still a batch process. For extremely high-volume manufacturing of identical small parts, a continuous furnace will almost always offer greater throughput and lower cost-per-part.

Increased Mechanical Complexity

The door and hoist mechanisms are more complex than those of a simple box furnace. This can translate to higher maintenance requirements over the life of the equipment.

Making the Right Choice for Your Process

Your decision should be driven by your specific priorities regarding production volume, material properties, and part geometry. Use these points as a guide.

- If your primary focus is achieving maximum hardness and minimal distortion in sensitive alloys: The rapid, integrated quench of a drop-bottom furnace is unparalleled.

- If your primary focus is high-volume, continuous production of uniform parts: A pusher or mesh belt continuous furnace will offer greater throughput and efficiency.

- If your primary focus is general-purpose heat treatment with a lower initial investment: A standard box furnace with a separate quench tank may be the most practical solution.

- If your primary focus is preventing surface reactions on parts that are not quench-sensitive: A dedicated retort furnace may be the most effective choice.

Ultimately, selecting the correct furnace is about aligning the equipment's core strengths with the non-negotiable requirements of your final product.

Summary Table:

| Furnace Type | Key Features | Best For |

|---|---|---|

| Drop-Bottom Quench | Integrated rapid quench, superior temperature uniformity, high flexibility | Sensitive alloys requiring fast cooling, variable part sizes |

| Standard Batch | Versatile, cost-effective, separate quench tank | General-purpose heat treatment with lower investment |

| Continuous (e.g., Pusher) | High-volume, consistent processing, automated flow | Mass production of uniform parts |

| Controlled Atmosphere (e.g., Retort) | Sealed chamber for precise atmosphere control | Processes needing surface protection from air reactions |

Optimize your heat treatment processes with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, enhanced by deep customization capabilities to meet unique experimental requirements. Whether you're working with sensitive alloys or need rapid quenching for superior material properties, KINTEK delivers precision and reliability. Contact us today to discuss how our furnaces can elevate your lab's performance and achieve your specific goals!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What role does a muffle furnace play in the preparation of MgO support materials? Master Catalyst Activation

- Can a muffle furnace be used for pyrolysis? Unlock Precise Thermal Decomposition

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis