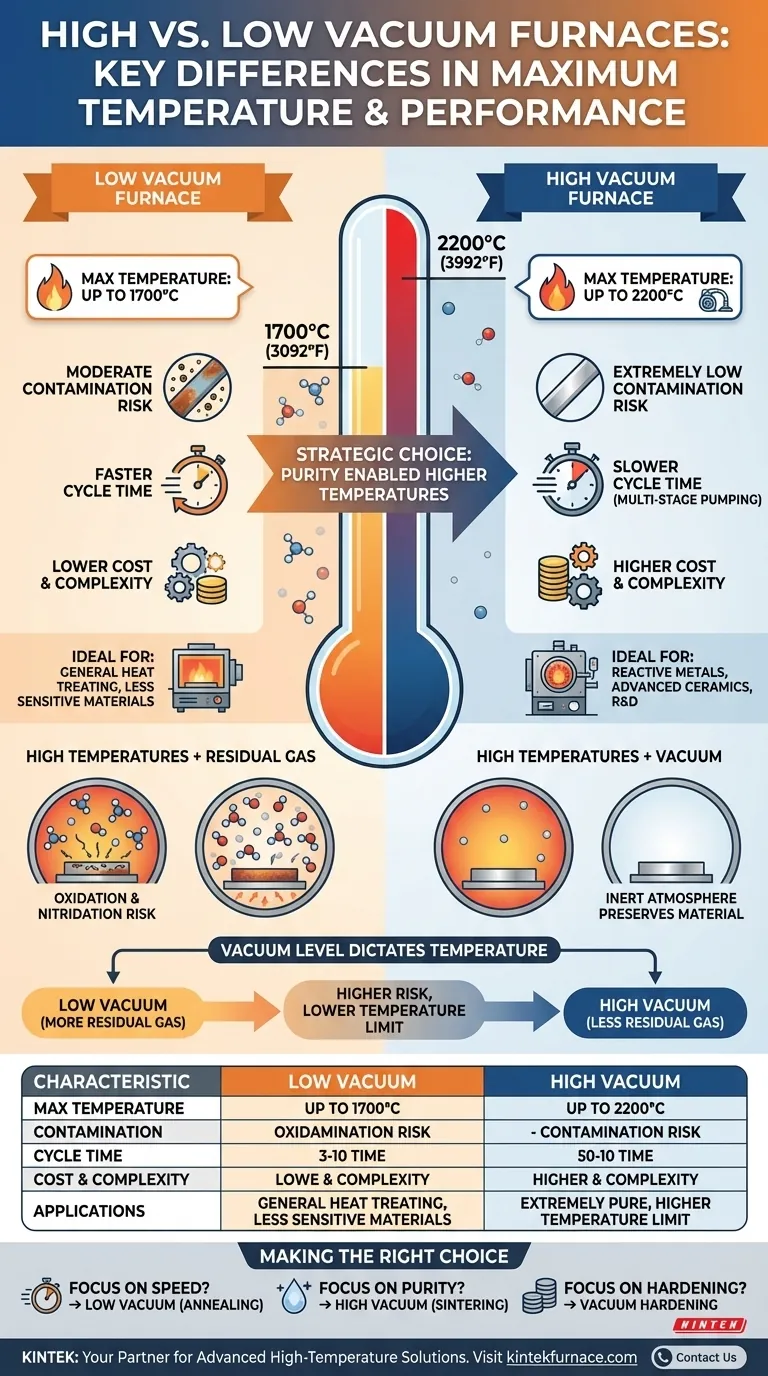

At a glance, the key difference is the maximum achievable temperature. High vacuum furnaces can operate at significantly higher temperatures, reaching up to 2200°C, whereas low vacuum furnaces are typically limited to a maximum of 1700°C. This substantial temperature gap is a direct consequence of the environment each furnace creates.

The decision between a low and high vacuum furnace is not merely about hitting a target temperature. It's a strategic choice driven by the need to control atmospheric contamination, as a higher-quality vacuum is the enabling factor for reaching higher temperatures without compromising the integrity of the material or the furnace itself.

The Role of Vacuum in High-Temperature Processing

To understand the temperature difference, you must first understand why a vacuum is necessary. At extreme temperatures, materials become highly reactive, and the components of the furnace itself are pushed to their limits.

Why a Vacuum is Essential

At high temperatures, the residual gases in a chamber—primarily oxygen and nitrogen—can aggressively react with the workload. This leads to undesirable outcomes like oxidation and nitridation, which can ruin the material's surface finish and structural properties.

A vacuum environment removes these reactive gas molecules, creating an inert atmosphere that protects the material during the heating process.

How Vacuum Level Dictates Temperature

A low vacuum (or rough vacuum) leaves a higher number of residual gas molecules in the chamber. As the temperature rises, these remaining molecules can still cause contamination or interfere with the heating elements, placing a practical ceiling on the furnace's safe operating temperature, typically around 1700°C.

A high vacuum, by contrast, removes vastly more gas molecules. This creates an extremely pure environment with minimal chance for reaction. This purity is what allows the system to be pushed to much higher temperatures—up to 2200°C—without risking damage to the workload or the furnace's internal components.

Comparing Low vs. High Vacuum Characteristics

The level of vacuum does not just affect temperature; it has a direct impact on contamination risk, cycle time, and the types of processes that can be performed.

Contamination Risk

A low vacuum furnace carries a moderate risk of contamination. It is suitable for processes where minor surface oxidation or reactions are not critical to the final product.

A high vacuum furnace provides an extremely low risk of contamination. This level of purity is essential for processing highly sensitive or reactive materials like titanium, refractory metals, and advanced ceramics.

Cycle Time and Pumping Systems

Low vacuum furnaces have faster pump-down and overall cycle times. They use simpler mechanical pumps to quickly remove the bulk of the air.

High vacuum furnaces are slower to reach their operating vacuum. They require a multi-stage pumping system, often involving a roughing pump followed by a turbomolecular or diffusion pump, to achieve the necessary low pressure. This adds significant time to each cycle.

Understanding the Trade-offs

Choosing between these furnace types involves balancing performance requirements with operational realities. There is no single "better" option; there is only the right tool for a specific job.

Speed vs. Purity

The primary trade-off is between processing speed and environmental purity. A low vacuum offers faster throughput, making it more efficient for high-volume, less-sensitive applications like basic heat treating.

High vacuum prioritizes purity above all else. The longer cycle times are a necessary compromise to ensure the material's integrity is perfectly preserved, which is critical for medical, aerospace, and R&D applications.

Cost and Complexity

Low vacuum systems are generally less expensive to purchase and maintain. Their simpler pumping systems and controls translate to lower operational complexity.

High vacuum furnaces represent a significant investment. Their sophisticated pumping systems, advanced sensors, and more robust construction demand higher capital expenditure and more specialized maintenance.

Making the Right Choice for Your Process

Your choice of furnace should be dictated entirely by the demands of your material and your final goal.

- If your primary focus is process speed for less sensitive materials: A low vacuum furnace is the more practical and cost-effective choice for applications like general-purpose annealing or tempering.

- If your primary focus is material purity and reaching extreme temperatures: A high vacuum furnace is non-negotiable for processes like brazing, sintering advanced ceramics, or treating reactive metals.

- If your primary focus is hardening steel with minimal surface change: A vacuum hardening furnace, which may operate in the low-to-medium vacuum range, provides a significant advantage over atmospheric furnaces.

Understanding these fundamental differences empowers you to select the precise tool required to achieve your material processing goals.

Summary Table:

| Characteristic | Low Vacuum Furnace | High Vacuum Furnace |

|---|---|---|

| Maximum Temperature | Up to 1700°C | Up to 2200°C |

| Contamination Risk | Moderate | Extremely Low |

| Cycle Time | Faster | Slower |

| Cost and Complexity | Lower | Higher |

| Ideal Applications | General heat treating, less sensitive materials | Reactive metals, advanced ceramics, R&D |

Need a furnace that meets your exact temperature and purity needs? At KINTEK, we specialize in high-temperature solutions tailored for your lab. Leveraging our exceptional R&D and in-house manufacturing, we offer advanced products like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, with deep customization to precisely fit your unique experimental requirements. Contact us today to discuss how we can enhance your material processing with reliable, high-performance furnaces!

Visual Guide

Related Products

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the significance of vacuum in relation to graphite components in furnaces? Prevent Oxidation for Extreme Temperatures

- Why is graphite a preferred material for heating elements in high-temperature vacuum furnaces?

- How does graphite contribute to energy efficiency in vacuum furnaces? Achieve Faster, More Uniform Heating

- What is the mechanism and effect of post-annealing NiTi thin films in a vacuum furnace? Unlock Superelasticity

- Why are vacuum furnaces used for the re-quenching of samples after a boriding treatment? Master Core Toughness